8020 Drawer Slides,Ogee Router Bit Lowes Windows,Jet Plane Used For Questions - And More

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser. It is a building system anyone can use to create custom solutions. We have Design Technicians, software and file resources, educational information, and more to partner with you every step of the way. Build your solutions with simple hand tools — no welding required. Adjustments and assembly are straightforward and fast.

Streamline Your System. Request Your Booklet. How To Video. Browse Categories. The cabinet is also bolted to the floor in two places, using the factory d-ring tie-down locations. I just ran an angle bracket off the framing over to the tie-down and ran the bolt through it.

I hope that helps! The biggest challenge will be building the drawer openings to the right dimension to accommodate the pre-made drawers you buy. I did the opposite—I decided what size drawers I wanted and built to that dimension. We are just starting our build in a Ford Transit and stumbled upon your youtube channel and website and both have been a huge help with design and build ideas. We purchased a few items through your affiliate links, the least we can do!

Thank you Luke, I appreciate the message! I really appreciate the support as well. Make sure you let us know your van is coming along.

One of these days I need to think about organizing a meet up. Thanks so much for all this information. May I ask what attachment method you used for the plyboo skins? I was looking into using sketch-up to design and was wondering if you created the extrusions in sketch-up or if you downloaded them somewhere.

I think you are doing a great job with your web site. I will definitely use your links for purchasing material knowing that you will get a little something out of it. Hi, I have the. You should be able to click and download it and make any modifications you wish.

Give it a try and let me know if you have any issues. I really appreciate the positive feedback! I built a similar cabinet, but the frame seems to rattle a bit. I only have it bolted to wall, perhaps bolting to the floor tie downs will help.

Rattling means something is loose. Have you checked all of the connection points? I did have rattling initially and discovered one angle bracket was only finger tight. To be honest I have yet to add it up. Stay tuned! Planning on following up your idea but with a Cruise 85 fridge little smaller as my version will be a little smaller. Hi, the Cruise has 2 plugs on each side of the refrigerator, on the inside of the unit. Hi, thanks so much for putting this up! Yes, the piece to the right is fastened to the frame with 3M very high bond VHB tape.

I did that because the bottom of the door has to clear the tracks that run across my floor. The fridge is an Isotherm Cruise Elegance. Hey man.

I am a big fan not only of your project and conversion, but the way you explain it and share with the rest.

So thanks a lot for that. I wanted to ask your opinion on a subject I have not found info. Have you done anything like this? Hi Rafa, I have done essentially that. For my galley, I have some small strips of closed cell foam between the aluminum and the body. If you watch my overhead cabinet framing video on youtube you should be able to see how those are implemented.

Good luck and thanks for the complements! There will be overlapping the will protrude over the passenger door as the basis of the galley cabinet I was looking at Sketchup Make AutoCAD look like grade 1 math and was wondering if you could recommend how you learned it? Its intimidating…. Not sure which platform you are on but give that one a try? I talked to the guys at and they use AutoCAD with their plugin. Apparently its quite easy with the plugin.

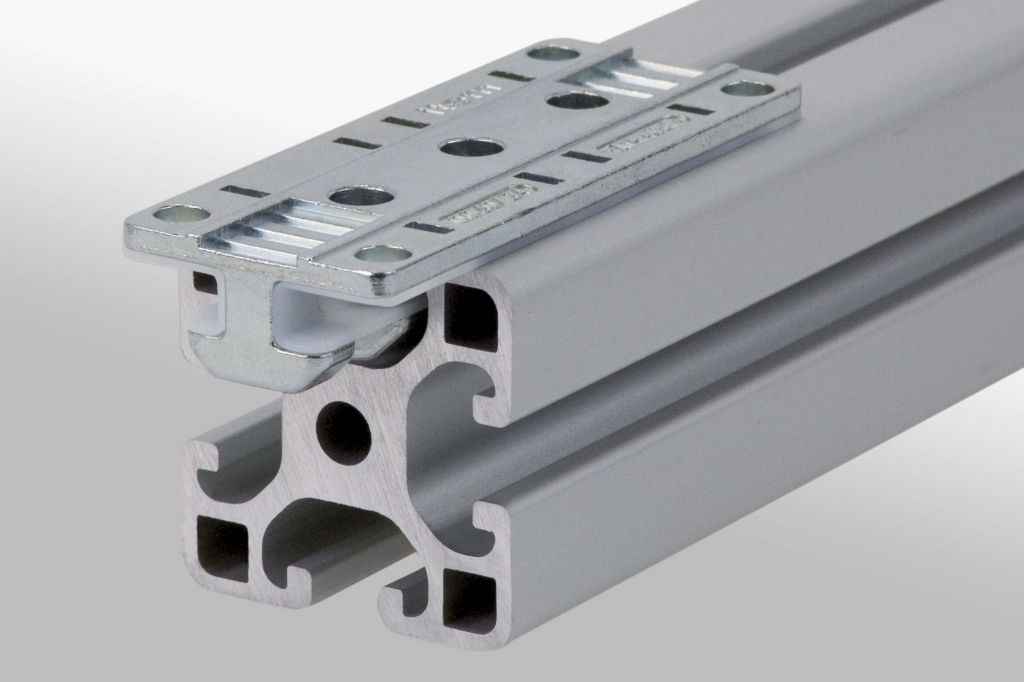

Hi Ken, I downloaded and tried Framexpert. I accomplished more in 10 minutes than 4 hours with Sketchup. You could do you entire galley in less than an hour. I am not sure why is not promoting the hell out of this tool. Oh good, glad to hear! Sketchup worked but was not the ideal tool. We had in the past constructed our own slide bearings out of lexan and tried a few other tricks to prevent binding and have been very successful.

I highly recommend its use for lifts. We have had great success with the linear slides in I would highly recommend them if you are looking for a light-weight, off-the-shelf solution. We used the english dimensions bearings, which proved to be very reliable and smooth over 3 or 4 competitions. The do have a tendency to come loose, which will cause the plastic slide to fall out the bearing.

Not good. This event has happened to us, as well as a couple other teams. With this quick, and simple fix, you will find that these linear slides are a great product. You can view pictures of our elevator from here. Feel free to ask any and all questions. Here are a few pictures of the linear bearings and our elevator.

|

Best Material For Router Table Top Jp Youth Bed Woodworking Plans 30 Woodwork Kits For Juniors Uk Yahoo |

TeReMoK

27.05.2021 at 17:15:15

Bakino4ka_fr

27.05.2021 at 22:56:39