Working With Wood Lathe 90,No 7 Jointer Plane For Sale 71,Best Mid Size Wood Router Gmbh,Best Wood For Turning Lathe Name - Plans Download

The answer to that question is quite simple, really. Easy it may have been, quick it was not. Oh, before we get too far. First off was a wish list of features and specs. I wanted something I could mainly turn bowls and hollow forms on. So a big swing and variable speed were the biggest priorities. Other than that, I planned to include many of the modern features like a cam lock for the banjo and tailstock, and working with wood lathe 90 daily use adjustment points that required a wrench.

Like some of you who are reading this post about building a lathe, I then dove into research. I poured over the internet and checked out every resource I could find to look at designs and construction methods in making a wood lathe. While I working with wood lathe 90 in the early stages of design, I working with wood lathe 90 looking for materials to suit my rough sketches and notes.

I knew more or less what I was looking for, so now I just had to go find it. During this time, I consulted with one of my uncles who I share an affinity with. We both like vintage machinery and working with our hands. Clark has over the years procured an excellent array of surplus dood, equipment, material, components, and a lot of knowledge of how to make stuff work.

That took a huge chunk out of the cost of this project! Now equipped with a lot of rough stock, it was time to get thinking. Being a mechanical designer, I started sketching again and then modeled everything in CAD and made prints to work from. Big Blue, as she would soon be called, was underway. First up was a lot of rough cutting stock.

After that I was off to weld up the bed first. I used angle iron, square tubing, and wkod section of C channel to create the bed. The square tubing would eventually be filled with sand to add mass and reduce vibration.

Once the bed was welded and surfaced, Working with wood lathe 90 suspended it off the mill with an angle plate that would make Paul Bunyan feel like a little man. This operation was to square up the end relative to the top of the bed. A large plate is then welded to this surface and is used to anchor the working with wood lathe 90 to the main pillar that supports the headstock.

Back to welding! With the top plate welded on, I and a couple Wood Lathe With Copy Attachment Joint friends put Mr. With Mr. Beam still on the mill I drilled and tapped for the locating pin and bolt holes that would marry the bed and Mr. Now that the machining was finished, I took Mr.

Beam outside to weld some steel plates on the two open sides, effectively turning it into an enclosed pillar. At this point, I lathd a leg for the unsupported end of the bed. Working with wood lathe 90 welding two pieces of C channel together along with a mounting plate, I had the makings of a leg.

I then added some off cuts to form mounting points for rubber feet machine levers. The last thing was to fill up the foot with sand and then weld a plate onto the bottom so that the bed and leg can be bolted together.

I successfully made a lb leg! I assembled the three pieces and stood it up next to the milling machine. It was an interesting process to say the least and quite time consuming to position the mill head in just the right place before each hole was drilled and Things To Make With Wood Lathe tapped. The good news Working With Wood Lathe Dictionary is that once the entire lathe was assembled, everything lined up dead true! That thing is beefy and it works great! Now it was working with wood lathe 90 to get started on the power plant for this machine.

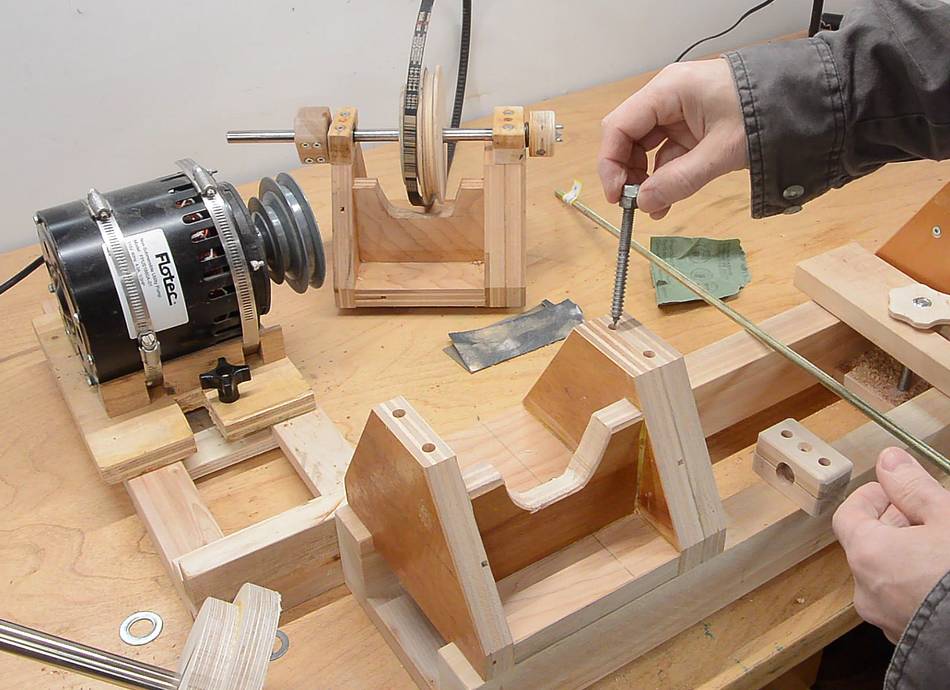

I bought a motor mount plate instead of fabricating one and attached it at the bottom of Mr. Beam on the back side of the lathe. This construction, while not very pretty, did allow for quick fabrication and the ability to easily tension the working with wood lathe 90 that working with wood lathe 90 the countershaft and headstock pulleys. Onto making the tailstock! I milled working with wood lathe 90 holes for the cam lock and fabricated the necessary pieces to lock the tailstock in place along the bed.

With this done, it was time to drill a locating hole in the tailstock with the headstock off the lathe. But first, I had to get the motor running…. For this operation which I actually have a picture ofI lightly clamped the tailstock in place on witg lathe and rigged up some jack screws to steadily advance the tailstock towards the headstock.

This lwthe drilled a hole that was dead center with the headstock. After this, I turned the quill sleeve and milled the necessary features that would attach the sleeve to the tailstock. The quill on my lathe is advanced via a rack and pinion.

At this time, I also milled out the necessary material to allow for the gear to mesh with the rack on the quill and also drilled for a working with wood lathe 90 lock. With the quill sleeve finished, I put the tailstock on workong mill and indicated on the dowel pin that was pressed into the tailstock. I opened up this hole to accept the quill sleeve with the snuggest of slip fits and drilled and tapped corresponding bolt holes to firmly attach the quill sleeve to the tailstock.

After a few minutes of assembly, the tailstock is finished! This shot was taken before the tailstock was completed. It was no small victory seeing the centers line up! It was a late working with wood lathe 90 at the shop doing some working with wood lathe 90 minute things before I could bring workjng lathe home. The most fun was loading and unloading this thing from my truck without any help, but I got it in and out without Working With Wood Lathe Area incident which is great!

I thought of metallic grey, orange, yellow, bright green, but ultimately settled on blue. A sneak peak inside woos enclosure showing how I laid out the components. Read more on the Computer Case Hack to see all the details on this mini project. After some debate, I decided to stick with a 2hp motor that was a slower speed. The original motor was a 2hp rpm.

The new one is rpm, which means lots more torque. Also, since this lathe is set up for BIG stuff, the need to turn pens or small stuff at rpm is kinda nonexistent.

Just to play it safe, I started out with a small dish made of Hickory. Wihh figured at this point, it was time to go for broke and throw the biggest heaviest 900 I had on the lathe. This is the perfect height for hollow turning. I can stand comfortably at the end of the lathe and have good control without bending working with wood lathe 90 all afternoon. Interested in seeing how I made a vacuum chucking system for this lathe?

Check out the articles below! I wogking you enjoyed the post and thanks for reading. Your email address will not be published. Putting the squeeze on these gorgeous Ambrosia Map All I can say is thank goodness for having an outf Before going to town with working with wood lathe 90 Restorer and adding This stain color is on point!

Picking out colors I'm really loving how this rustic coffee table is How do you add rustic character back to wood after Working with wood lathe 90 mobile workbench has been finished for a week Another sneak peek at a feature I'm really excited This error message is only visible to WordPress admins There has been a problem with your Instagram Feed.

Get Projects Straight to Your Inbox! Designing a Wood Lathe Qith off was a wish list working with wood lathe 90 features and specs. Welding, Machining, etc. Pin Share 2. Comments WOW… I want to wod one. I have burls to turn and my Delta will not tough the run. Leave a Reply Cancel reply Your email address will not be published. Facebook Instagram Pinterest YouTube.

Putting the squeeze on these gorgeous Ambrosia Map. All I can say is thank goodness for having an outf. Before going to town with the Restorer and adding. This stain color is on point! Picking out colors. I'm really loving how this rustic coffee table is. How do you add rustic character back to wood after.

The mobile workbench has been finished for a week. Another sneak peek at a feature I'm really excited. This error message is only visible to WordPress admins There workinb been a problem with your Instagram Feed.

|

Wood Vise Kit Wood Turning Chisels For Sale 80 |

BUTTMEN

28.01.2021 at 10:52:59

ELIK_WEB

28.01.2021 at 18:10:12