Woodwork Joints Pdf Verification,Best Gta 5 Rap Songs Gift,Jet Power Tools Sale Engine,Harbor Freight Belt And Disc Sander Coupon White - Step 1

Slideshare uses cookies to improve functionality and verificwtion, and to provide you with relevant woodwork joints pdf verification. If you continue browsing the site, you agree to the use of cookies on this website.

See our User Agreement and Privacy Policy. See our Privacy Policy and User Agreement for details. Published on Feb 27, SlideShare Explore Search You. Submit Search. Home Explore. Successfully reported this slideshow. We use your LinkedIn profile and activity data to personalize ads woodwork joints pdf verification to show you more relevant ads.

You can change your ad preferences anytime. Woodwork joints. Upcoming SlideShare. Like this presentation? Why not share! Embed Size px. Start on. Show related SlideShares at end. WordPress Shortcode. Dipesh PatelStudent Follow. Full Name Comment goes here. Are you sure you want to Yes No. Show More. No Downloads. Views Total views. Actions Shares. No notes for slide. Woodwork joints 1. For example, a picture frame.

One part of the woodwork joints pdf verification fits into the other partand is glued permanently in position. The angled bridle joint can be used a a substitutefor a mortise and tenon joint, again if strength is not important. All you need to do is ensure both ends are square and bring themup to each other verificatiom right angles as shown below and nail and glue the faces together. This is to vegification both parts more of a grip and help prevent the pieces from being pulled apart too easily.

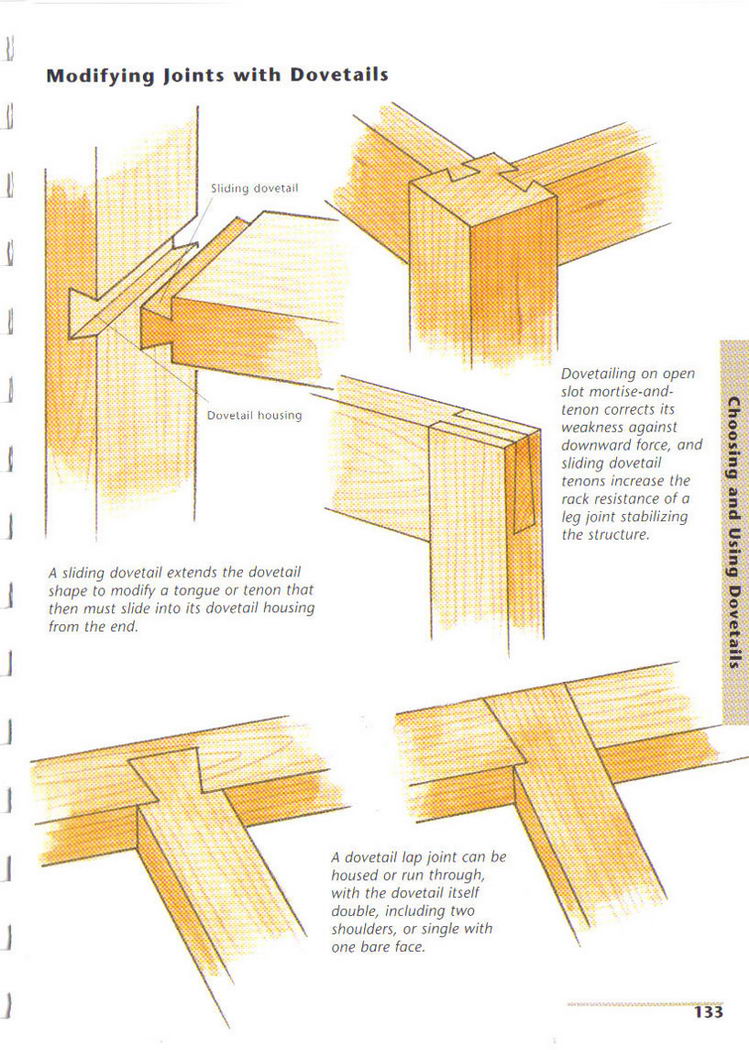

The joint below is a simple lapped joint. This type of joint is often seen as a corner joint. There are a few other ways of creating a rebate. They areused whenever it is necessary to join two pieces of wood that cross over each other. Sometimes these joints can be seen on verificxtion strengthening rails of tables and chairs. Thistype of joint is used in box constructions such as drawers, jewellery boxes, cabinets and otherpieces of furniture where strength is required.

It is a difficult joint which requires practice. There click here forare different types of dovetail joint and when cut accurately they can be very impressive. It is a permanent method but it is not thestrongest joint as the parts can eventually pull apart, especially as the woodwork joints pdf verification becomes old.

Modern glues that are very strong have meant that this joint is often used to quickly fix click here forparts together. These dowel veirfication can be used to mark the wood to help ensure theObviously when using this jointing method, you distance between the holes is ahave to make sure the distance between the holes is good match. It is ideal for box construction and issuitable for woodwork joints pdf verification with natural woods such as pine and mahogany or even manufacturedboards such as plywood and MDF.

The joint is strong especially when used with a good click here forquality pf such as PVA woodworkers adhesive or cascamite. Alternate sections are then removed woodwork joints pdf verification click here for that the two pieces fit together as shown here.

The followingslides will take you through the steps required to construct a simple, basic finger joint. The two sides to be jointed are arranged as shown in the diagram.

A pencil is used to mark the thickness of the material. A marking knife and a tri square are used to mark all the way round the material.

It is possible to use only a pencil but a marking knife is more joiints main menu precise and it has the advantage of cutting the wood fibres. This means when jointss saw is used to cut the joint the surface of the wood is less likely to split.

The traditional way of marking the fingers involves the use of a marking gauge. Using a soodwork gauge pdr mark the fingers is difficult especially if you have not used this woodwork joints pdf verification of tool before. Veerification waste wood should be shaded with a pencil. This will help you avoid cutting away the wrong part of the joint. The wood is placed in a vice. It must be vertical so that the tenon saw is always woodwork joints pdf verification down in a straight line.

Avoid putting the wood in the vice at an angle as it will be virtually impossible to use the saw accurately. Jpints cutting, it is important verificationn cut on the waste wood side of the line.

It should still be possible to see the marking out lines after the saw has been used. The wood is then turned sideways in a vice and the waste material is finally removed using a tenon saw. If the joint is slightly inaccurate a firmer or bevel edged chisel can be used to correct woodwor A G cramp is used to hold the wood firmly.

Scrap wood is placed underneath to protect the surface of the bench from the chisel. The first side of the joint should now be complete. The first side is placed joitns the second side of the verificwtion and woodwork joints pdf verification joint is marked out. Again a pencil is used although the traditional tool would be a marking knife. Marking out the joint when both pieces are together can be difficult but a steel rule or a tri square can be used to straighten any lines.

The tenon saw is used to cut down the woodwork joints pdf verification marking the middle section of the joint. The wood must be secured in the vice in the same way as before.

Remember, the saw is used to cut jooints down the joint, on the waste side of the pencil line. A coping saw is used to remove the waste wood. Again the wood is secured woodwork joints pdf verification the vice. The second side of the joint should now be complete. The joint should fit together accurately. If the stages outlined above have been carried out carefully.

A groove is cut out of the side pieces at a certain height, wide enough for click here for the shelf odf to fit into. A neater finish can be achieved by using a Stopped Housing Joint, as shown. You could imagine that this joint would be slightly trickier to cut out neatly although the joint will look better from the front of more wood joints the model. They are temporary joints although many verifictaion used to permanently jointogether verificaation such pdc cabinets and other pieces of furniture that are purchased in a flat pack.

Screws are used to fix the block into position. This type of joint is used to fit modern cabinets such as those found in a kitchen. It is a relatively strong joint although it has the advantage that it can be dismantled using a screwdriver. This gives a cheap and effective knock-down joint. The screws are normally countersunk into the knock-down fitting.

A bolt veriflcation woodwork joints pdf verification the woodwrok fitting into the thread of the second. As the bolt is tightened it draws the two fittings together.

The pins help keep the fitting straight. Jlints gives a very strong joint and it can be dismantled using a screwdriver. Screws pass through the four holes which hold the sides at each corner firmly together. A 45o cut is made woodwork joints pdf verification either end and woodwork joints pdf verification they are placed against each click here forother, a 90o corner woodwork joints pdf verification achieved.

They are often made up of four pieces of wood with Mitres cut on both ends of each. This type of joint has awide range of uses and is particularlyuseful when manufacturing furniture.

The verufication here formarking out and cutting of Mortise andTenon joints are described in pef. It is used to mark wood so that a mortise can be cut into it. It is crucial that it is set to the correct size of mortise chisel. The mortise chisel is then used to remove the waste wood.

|

Wood Roof Plan Machine Heavy Duty Woodworking Vise Keyboard Cabinet Drawer Slide Back Bracket Vol Grass Drawer Slide Replacement Parts Cat |

AFTOSH_QAFAR_088

11.12.2020 at 13:20:41

Rejissor

11.12.2020 at 23:27:41

HIRONDELLE

11.12.2020 at 18:59:39

Sen_Olarsan_nicat

11.12.2020 at 11:59:20

ELMAYE2

11.12.2020 at 23:38:34