Setting Up A Kreg Jig Reviewer,Wood Shop Vacuum Setup Tool,Pdc Machines Stock Warehouse - Plans On 2021

Standard guides work for anything up to four inches wide. After that, you just keep adding holes six inches apart until you're done. Thickness: Most jigs work with a minimum thickness of Kreg Jig Setting For 2x6 Zone one-half inch.

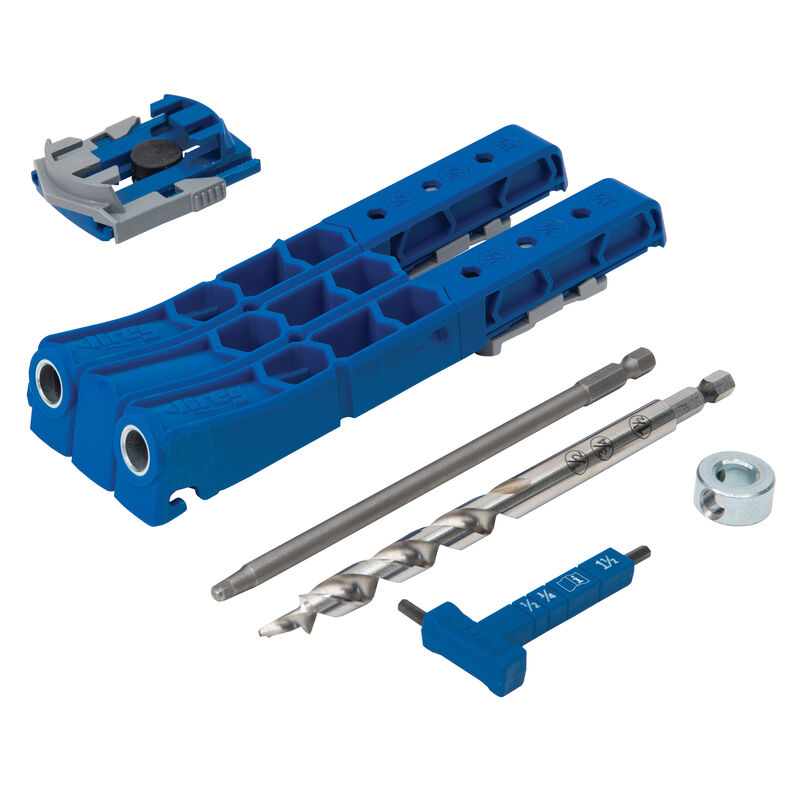

Maximum thickness is approximately one and one-half inches, which is the actual size of all 2x posts and boards such as 2 x 4s and 2 x 6s. Pocket-hole jigs have three basic components:. Drill bit with adjustable collar to set correct depth; Too shallow and the joint won't be strong. Too deep and the point of the screw might go through the joint, marring the outer surface. The Kreg Tool Company doesn't just make pocket-hole jigs.

There is also a handy decking jig so you can fix your boards without ugly nail heads showing , a specialist drawer-side jig of particular interest to cabinetmakers , and several other additions. However, they are all variations of the pocket-hole idea, so that's what we're focusing on here. The accuracy of the drill guide is vital.

Some manufacturers use aluminum. It's light, so it's easy to move around, but it's prone to wear, particularly from a high-speed steel drill bit.

Kreg Jigs are made from a nylon material reinforced with fiberglass. The tough composite then has hardened steel drill guides inserted, which come with a lifetime warranty. This ensures precision and repeatability. Clamping the workpiece firmly in the jig is another important aspect. Wood is soft, so the clamp can't be too aggressive or it will mark the surface. Some makers use a threaded version. Kreg favors a toggle clamp which has more positive closure or, on the top-end K5, an adjustable ratchet.

If the material is too large to move to the jig, Kreg drill guides are all demountable, and each has its own specific clamping point. This gives unrestricted mobility, and it means you can often carry out furniture repairs in situ. If you buy a full Kreg Jig system, you'll find a clamp included the K5 model is even self-adjusting.

Many DIY woodworkers, as well as professionals, already own C-clamps that will do the job. Setting up the jig has to be clear and simple. Measurements on Kreg Jigs are molded into the body so there's no mistake. Hole depth and screw size charts are also provided. Nothing is left to chance. You have a choice of jig systems. You can buy a comprehensive system like the K5, or start smaller and add components as you need them. Kreg will even sell you a case to keep them all in!

Waste always presents challenges to woodworkers. The bench-mounting Kreg jigs have expanded recesses for better chip clearance. Some have dust extraction ports. We looked at a number of cheaper pocket-hole jigs that compete with Kreg. The main problems with them are excessive play in the components which makes accuracy very hit-and-miss and less robust construction.

In general, they aren't as versatile, and most are two-hole rather than three-hole systems. Kit contents can appear impressive, but the numbers are often padded with small items like screws or dowels. A Kreg Jig is an investment, though it doesn't have to be a large one. That's not a great deal extra for the long-term accuracy and durability that has made Kreg the market leader.

With any jig, setup is key. Don't rush things, particularly when you first get your jig. The old woodworker's adage of "measure twice, cut once" is true here, too. The most common mistake comes when setting the jig and drill collar to the thickness of your wood.

Check twice, drill once. Although pretty straightforward, initial testing with a few pieces of scrap wood is a good idea to get used to the way the jig works. You can fix errors. If you do make a mistake, you can make almost invisible repairs with a Kreg pocket-hole plug cutter. This cuts wooden plugs the same size as your hole. Glue in the plug, sand it down, and nobody will be any the wiser! In theory, no. In practice, many professionals recommend it.

Wood — even plywood — will expand and contract as humidity changes. So it's possible screwed joints can work loose over time. A little wood glue will ensure your joints remain solid. Kreg Jigs are designed to allow you to make strong joints, regardless of material widths. For instance, if you have boards two to three inches wide, you would use guide holes A and B. For narrower material, you would use B and C, and so on. Instructions are included with your jig, including recommendations when fixing much wider panels.

Lots of places. Besides the Kreg website kregtool. Both have clear tutorials, dozens of tips and tricks for using a Kreg Jig, and literally hundreds of interesting projects, too. Beware, though — Kreg joinery can get a bit addictive! It will also tell you what length screw works best for your wood thicknesses. Make sure to choose the correct joint type for your joint. Always test unfamiliar screw and jig setting combinations before using on your actual project.

Do your edge to edge calculations work for my frame? Thanks for all your efforts. Hi Robert, yes the calculations should remain the same even for a corner miter joint. Hi, using the thinnest board to set your jig is a good rule of thumb, but the calculator is meant to give more precise results. Pin 15K. Share Inches Metric.

|

Woodworking Cnc Tools Market 65 Under Drawer Runners Editor |

BAKU_OGLANI

07.09.2020 at 23:32:47

AuReLiUs

07.09.2020 at 16:37:55

ayka012

07.09.2020 at 19:28:59

sex_ledi

07.09.2020 at 17:35:33