Quick Release Vise Mount Yield,Small Wooden Spindles 3d Model,Install Side Drawer Slides 4g - Try Out

The dynamic jaw explained later is designed to hang over the edge of the table. Although vises are primarily designed to hold a work pieces horizontally, the overhanging front jaw does permit the holding of objects vertically. Despite the many different types, shapes, and sizes vises most vises consist of the following major components. Casting is the most common and cost effective manufacturing process. It involves pouring hot liquid metal into molds.

Once poured into the mold the liquid steel is allowed to cool. After cooling and hardening the molds are removed leaving a finished shape. This process is used to manufacture the static and dynamic jaws. Although cost effective, there are several drawbacks to this production method including a rough final surface finish and the possibility of impure casting and thus a weaker, compromised part.

The forging production method is more costly. However the result is a superior quality product with greater tensile strength, typically expressed in pounds per square inch PSI. Unlike casting, the forging process uses solid blocks of steel that are heated and then pounded into their required shape. This production method is common in the tool industry when manufacturing wrenches and pliers.

In addition to differences in production method, the materials used to make vises also differ. Two of the most common materials used are Gray or grey and Ductile iron. The primary difference between Gray and Ductile iron is the type and structure of the carbon present within them. The carbon type and structure provides different product characteristics, which we will examine below.

As with any tool purchase, careful consideration of how the tool will be used is paramount. Before making a final decision consider the checklist list below:. Look for a bench vises with integrated pipe jaws. These extra jaws are located in the throat of the dynamic and static jaw and are serrated and curved specifically to hold pipes. Determining the max pipe diameter is important in determining the size of vise you will need.

These sizes refer to the width of the jaws. The larger and heavier the object to be held the larger the vise required. As a general rule of thumb, the maximum throat depth is typically proportionate to the jaw width. In some instances in order to accommodate an odd work piece a o swivel base is needed.

If you think you will need to adjust vise position on the bench, look for a vise that offers an optional swivel base. Otherwise, consider a speciality vise such as offset or rotating model. While a well manufactured vise should deliver years of reliable service some parts such as the jaws can simply wear out.

If you know you will use your vise heavily plan ahead and look for a brand with replaceable serrated jaws and comprehensive spare parts support program. If hammering or shaping represents a significant part of your work, consider a vise with a large rear anvil.

A forged model will likely also be worth the extra investment. Look for a vise with a quick release opening system. Vises with this feature open without the need to manual unwind the lead screw. This can be a time and frustration saver. Product successfully added to your Shopping Cart. Bench Vise Styles For the purpose of this article, we will be focusing on the metalworking vise, often referred to as the Engineer's, Mechanics, Combination, or Tradesman vises.

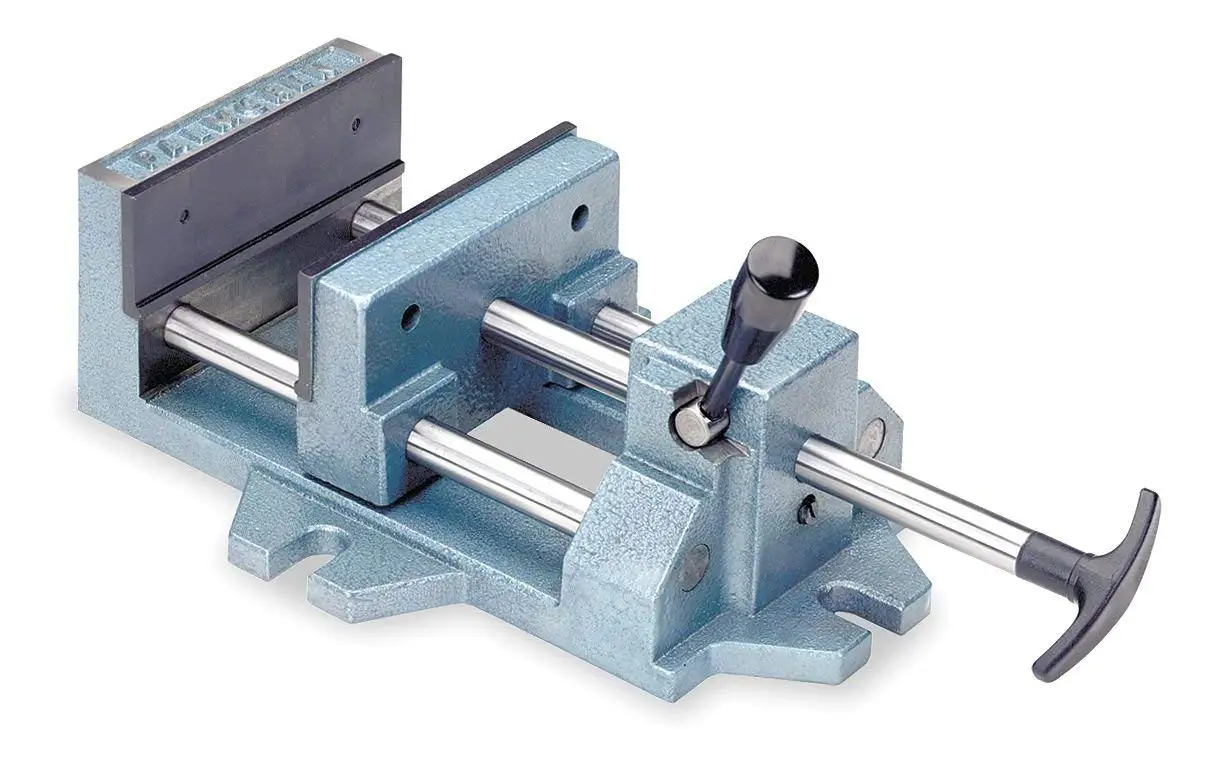

In terms of shape and design, metalworking vises can vary in many ways, as seen below: Despite the many different types, shapes, and sizes vises most vises consist of the following major components. Anatomy of a Bench Vise Sliding or Dynamic Jaw — the jaw closest to the operator that has the handle protruding through it.

It is referred to as the dynamic jaw as it is the jaw that moves open and closed. The dynamic jaw applies or relieves clamping pressure. Fixed Body or Static Jaw — the static jaw is typically the heavier of the two jaws and, as its name implies, remains stationary during operation. I wanted to add that I've seen a number of people complaining about the quick release not working even though the vise is brand new. I had the same issue and I realized that I actually had the quick release nut in backwards.

Once I reversed it, the problem was solved. I wonder how many people have returned a perfectly good vise because they didn't realize this had happened. I mentioned in my other review that you also need to drill bigger holes than what seems necessary or you'll have a really hard time with this.

Apart from poor installation instructions, this seems like a good buy so far. I've been a professional woodworker since , I've dealt with all kinds of woodworking tools and such in the past 40 years. There is nothing wrong with this vice, if installed and cared for properly. A little patience, a little bit of quality lubricant appropriate for the screw, and this vise is really hard to beat.

Mine works easily and perfectly. I highly recommend this vise, and give it 5 stars. I got this on a whim when I just suddenly became fed up with trying to use clamps. Even when considering to buy it I was worried about the quick release mechanism, turns out I was right.

Mine came with no instructions and no information what so ever. After quite a bit of doing I installed it on my bench and it worked okay for a 2 to 3 years usually holding tight when needed. Before long it would release randomly when clamping something small now it will just release when the slightest tension has been added.

I don't think I have to tell you that a vise that doesn't hold work is just worthless. Don't bother with the quick release, go with reliability instead. The quick release mechanism is so poorly machined that the vise can only be opened and closed by an elaborate fiddling procedure. Each time I tighten it moderately, avoiding wracking I fear it will entirely fail. Saving money on cheap vises that compromise your workbench is a big mistake.

Dont waste your money on this. The quick release is useless. The vise come loose easily. Poor quality steel on the threaded rod. This is an update from my January review. While doing some light testing after install, the cam snapped just like an earlier review. I contacted Woodcraft, and since it was within the 90 guarnantee window, they sent me out a new cam the next day.

Well, I took my bench apart to install the new cam and have been using the vise on and off for 5 months, being incredibly careful about clamping distribution and torque. Yesterday, the exact same piece snapped in the exact same spot. This is a major fault, and I would not buy this product until WoodRiver can re-design the cam mechanism. Woodcraft, however, has been very helpful through the whole process. Added it to my new work bench.

So far no problems. Grips well. I am still getting the hang of the quick release mechanism but then I am a slow learner. For those anoyed with the factory handle just go out and buy a 12" pipe nipple and two end caps. Works great half the price. Used the same handle in my Wood River end vice.

Have been using my vise for a month now with no problems, and no racking. Vise is very sturdy and holds objects tightly, however, the vise does not come with mounting instructions, templates, or hardware.

Installed vise a year ago and used it intermittently since then. Just started to do some real work with it recently and on the first use, the quick-release cam mechanism snapped Pressure applied at the time was significant and balanced, but not more than one would expect to hold a piece of wood firmly. You get what you pay for I've got two of them The instructions, although not written for 8th grade reading like Military Field Manuals, were just doable.

The handle you guys sell is too small like Dave O says, about 1. The hardware i.

|

Kreg Pocket Hole Jig 2x2 Full Berkshire Products Lumber Education Cheap Woodworking Projects Review |

Lihon

27.07.2020 at 13:58:39

LORD_RINGS

27.07.2020 at 13:15:44