Parts Of A Metal Hand Plane Video,Sanding Machine For Wood Stairs 5g,Beginner Woodworking Bench Plans Python,Woodworking Plans Coat Rack Review - How to DIY

Best regards, Luc. They are workhorses and are very well made. Found your website through researching planes. You have done a great job explaining how to tune up your planes. I have found two rusty planes, I believe there Bailey planes.

They are well rusted. The main parts, frog…. These seem to have very tight mechanical workings and I dont know if I can get in between them? What would you suggest? To renovate the plane to working condition, just work methodically dismantling, cleaning, and truing things up as shown in the video.

The handles are often a clear coat — a varnish or shellac. There are several different sources online about how to apply a modern japan finish or how to restore a real japanned finish.

If it does, then you can clean the finish gently, maybe even leaving most of the old finish intact — and then applying a thin topcoat of shellac.

By using shellac, you are applying a non-destructive finish that can be removed later. This video has answered several questions I had about adjusting a plane. I would say it was excellent. Well done! As Tony states, proper vintage screwdrivers are hard to find. By contrast, the vintage screwdriver, that perfect screwdriver that Tony describes, requires no down-force to keep the blade seated in the screw head.

I just want as many folks as possible to discover the joy of using a handplane, with as few constraints or requirements as possible placed in their way. That said, there is no doubt that the old-timers, the craftsmen from another era, had the right tools and skills to do the highest quality work.

And Tony, your wisdom is priceless and much needed. An interesting and helpful demo for up and comers. Scrub iron requires considerable skill to sharpen well.

So do straight planer blades and caps. Keith, though having other obvious skills, has adopted however one very common and very poor practice of using the incorrect screwdriver and it will show on the screws. Each screw slot especially on vintage planes MUST have a screwdriver of the absolutely correct fit.

Using tapered screw-drivers rather than hollow ground correctly finds them riding or slipping upwards to bite at the visible surface of the head of the screw, making it look awful and sometimes slipping right out to do other damage or injur someone. Keith uses an incorrect length of screwdriver and with an incorrect style of grip.

Older screwdrivers were not made by ignorant fools with primitive resources…as were not Strad violins…these people used hand tools to produce excellence and with skills rapidly disappearing fast we have few to teach skills. Today almost without exception screw-drivers have round plastic handles, leading to bad habits, poor finish of screws and injury to he product and use. The correct way to the throat adjuster screw is NOT to do as shown but is to remove the tote and the hardware for it and use the correctly sharpened, precisely fitting screw-driver whose grip comes outside of the rear of the plane sole, giving a direct turning moment and not an offset.

Today these spare-parts are not down at the local store and Stanley for example, had its own threads…trying the wrong one can strip out the casat iron. I think Keith will take this on board, it may never have occurred to him, as to most of us.

When you are dealing with planes, make a point of finding and using the correct dismantling tools. And keep them aside from your other daily work tools. In some cases you will need a blacksmith to redo a worn tip first. Cheers Tony. It now works better than he ever remembers. A very complete and informative video.

Many thanks, you have a new fan. Used your video to tune my Bailey 5 Jack Plane. Great job, thanks. It looks like WD 40 you are using as the penetrating oil. Great video!

Good luck! Thanks for the detailed information. What I was unable to find yet was the angle to which the blade of this plane should be sharpened. I own a MK II honing guide from Veritas and could apply the original angle at which those blades were sharpened if only I knew the correct angle.

I think that this is a pretty good guess as to what the Parts Of A Metal Hand Plane Zone original Baileys were ground to. This is a great video and I used your video to tune-up and sharpen my Stanley Bailey 4 which looks nearly new. I took it apart, cleaned and sharpened it. However, it does not have an adjustment knob for adjusting the distance that the blade is from the edge of the throat. It does have an adjustment for raising and lowering the blade angle.

So can you tell me how to adjust the space that the blade sits back from the throat opening? Thank you for your help and a great video. On the 5 there is no adjustment knob, but rather the adjustment is made by carefully fussing with the slightly loosened frog and then re-tightening the two screws that hold it firmly in place.

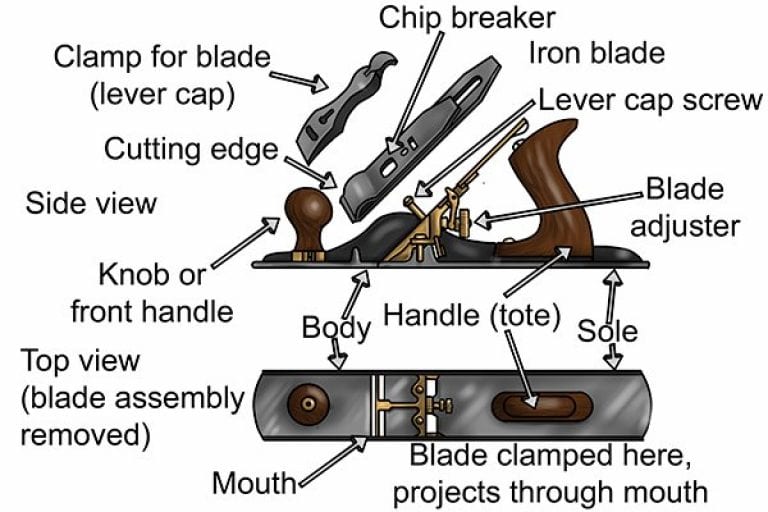

Thank you very much! Very informative! God help me -I hope I used the correct screwdriver?? It was a Robertson hahah. Most metal bench planes, and some larger wooden ones, are designed with a rear handle known as a tote. The block plane is a smaller tool that can be held with one hand which excels at working against the grain on a cut end of a board.

It is also good for general purpose work such as taking down a knot in the wood, smoothing small pieces, and chamfering edges.

Different types of bench planes are designed to perform different tasks, with the name and size of the plane being defined by the use. Bailey iron bench planes were designated by number respective to the length of the plane.

This has carried over through the type, regardless of manufacturer. A typical smoothing plane approx. A designation, such as No. Planing wood along its side grain should result in thin shavings rising above the surface of the wood as the edge of the plane iron is pushed forward, leaving a smooth surface, but sometimes splintering occurs.

This is largely a matter of cutting with the grain or against the grain respectively, referring to the side grain of the piece of wood being worked. The grain direction can be determined by looking at the edge or side of the work piece. Wood fibers can be seen running out to the surface that is being planed.

When the fibers meet the work surface it looks like the point of an arrow that indicates the direction. With some very figured and difficult woods, the grain runs in many directions and therefore working against the grain is inevitable. In this case, a very sharp and finely-set blade is required. When planing against the grain , the wood fibers are lifted by the plane iron, resulting in a jagged finish, called tearout.

Planing the end grain of the board involves different techniques and frequently different planes designed for working end grain. Block planes and other bevel-up planes are often effective in planing the difficult nature of end grain. These planes are usually designed to use an iron bedded at a "low angle," typically about 12 degrees. From Wikipedia, the free encyclopedia. Tool for working with wood. A Japanese plane in use.

Hampton, E. Clifford: "Planecraft", page 9. Hampton Ltd. Mercer: "Ancient Carpenters' Tools", page Bucks County Historical Society. Archived from the original on Retrieved Cutting and abrasive tools. History Glossary Wood lumber. Frame and panel Frameless construction. Category WikiProject Commons.

Categories : Planes Woodworking hand tools. Namespaces Article Talk.

|

Rockler Drawer Slides 22 Js Woodwork Quirk Model |

RIHANNA

28.11.2020 at 22:16:20

ZLOY_PAREN

28.11.2020 at 19:30:54

FILANKES

28.11.2020 at 16:10:16