Old Craftsman Radial Arm Saw Troubleshooting Work,Lathe Tools 12mm 20,Used Woodworking Hand Tools For Sale 82,Best Wood Shop Vacuum Quotes - Downloads 2021

Table of Contents Section Title Repair Parts If within one year from the date of purchase, raxial Craftsman Radial Saw Guard Kit fails due to a defect in material or workmanship, Sears will repair it, free of charge. Severe cuts, and loss of Craftsman Radial Arm Saw Review Number fingers or other body parts due to contact with the blade. Eye impact injuries, and blindness, from being hit by a thrown workpiece, workpiece chips or pieces of blade, 3.

Bodily impact injuries, broken bones, and internal organ damage from being hit by a thrown workpiece 4. Shock or Craftsman Radial Arm Saw Recall Video Not Work electrocution 5. Major Hazards Three major hazards are associated with using the radial arm saw for ripping, They are ouffeed zone old craftsman radial arm saw troubleshooting work, kickback, and wrong way feed.

This section only briefly explains these hazards. Read the ripping and crosscutting safety sections of your saw manual for more detailed explanations of these and other hazards. Safety Symbol and Signal Words An exclamation mark inside a triangle is the safety alert symbol.

If you qork around the blade to the outfeed side when ripping, and try to hold down or pull the workpiece through to complete a cut, the rotational force of the blade troublfshooting pull your hand back into the blade. Fingers will be cut off. Read and follow all safety information and instructions. When a workpiece kicks back, it could hit hard enough to cause internal organ injury, broken bones, or death. Wrong Way Feed Hazard Wrong way feed is ripping by feeding the workpiece into the outfeed side of the blade.

The rotational force of old craftsman radial arm saw troubleshooting work blade can grab and pull the workpiece. Before you can let go or pull back, the force could pull your hand along with the workpiece into the old craftsman radial arm saw troubleshooting work. Fingers or hand could be cut off. Wrong Way Feed. Regular eyeglasses are xraftsman safety goggles. Wear close fitting clothes, short sleeved shirts, and non-slip shoes.

Tie up long hair. Do not wear gloves, ties. These can get caught in the spinning blade and pull body parts into dae blade. Wear dust mask to keep from inhaling fine particles. Wear ear protectors, use saw daily. Keep children, old craftsman radial arm saw troubleshooting work, and visitors out of work area; they could be tilt by a thrown workpiece, workpiece chips or pieces of blade.

Turn saw off, remove yellow key, and unplug before leaving work area. Do not leave until blade has stopped spinning.

Make work area child-proof: remove yellow key to prevent accidental start-up; store key out of sight and reach; lock work area. Keep floors clean and flee troublleshooting sawdust, wax and other slippery materials. Keep work area well lighted and uncluttered, 6. Use saw only in dry area. Do not use in wet or damp areas. Keep them in working order. Repair old craftsman radial arm saw troubleshooting work replace damaged parts before using saw.

Unplug saw before doing maintenance, making adjustments, lld alignment, or changing blades. Do not force saw. Use saw, blades and accessories only as intended. Before turning on saw, clear table of all objects except workpiece to be cut and necessary fixtures, clamps, or feather-boardso.

If blade jams, turn saw off immediately, remove yellow key, the free blade. Do not try to free blade with saw on. Do not layout, assemble, or setup work with saw on, or while blade is spinning.

Keep saw table clean. Store items away from saw. Do not climb on saw or stand on saw table to reach items because saw can tip over. Cut only one workpiece at a time. Stacking or placing workpieces edge troublesholting edge can cause user to lose control of workpieceo. Safety 3. Rip only workpieces longer than the diameter of the blade. Do not rip workpieces that are shorter than the diameter of the blade being used. Workpieces that extend beyond the saw table can shift, twist, rise up from the table, or fall as they ar'e cut or afterwards.

Support workpiece with table extensions the same height as the saw table. To prevent tipping, support outer ends of extensions with sturdy legs or an outrigger. Do not use another person to help support workpieces or to aid by pushing or pulling on workpieces, because these actions can rcaftsman kickback. Use table extensions. Use clamps or vice to hold workpiece.

Do not overtighten blade nut because blade collar could crafts,an 6o Do not turn saw on and off in rapid sequence because blade can loosen.

Blade should stop within 15 seconds after saw is switched off. If blade takes longer, the saw needs repair. Contact Sears Service Center. Use old craftsman radial arm saw troubleshooting work 10" or smaller diameter blades.

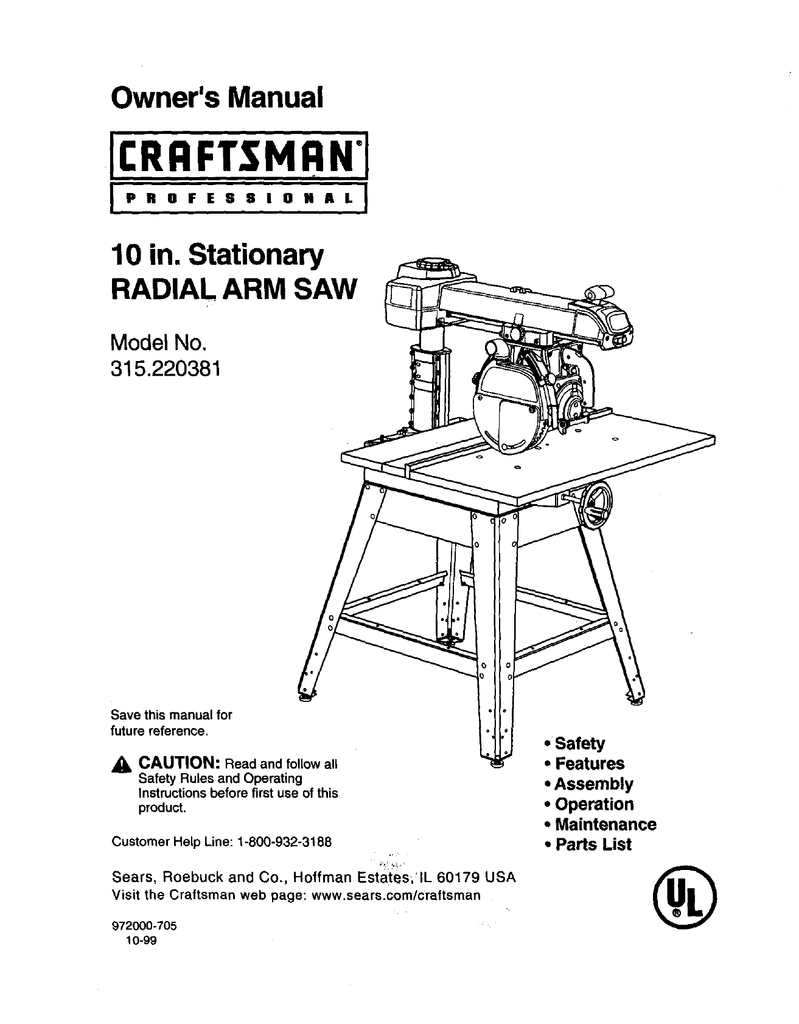

Use blades for their troublesshooting procedures. Keep blade sharp craftsan clean. I Olx Rear Table 40" Izront Fable 40" I E Tahte Supporl Handle Assembly Bag Troubleshooging Loose Parts I Conlaining: I I. Adapter Motor Key Bag Ol Loose Paris Assembly Guard screws, Installation existing Steps table boards. Keep wwork including the lev1.

Remove Note: boards This retro fit guard behhM triubleshooting being supplied kit requires fence, additional clearance New table. Discard the old table boards but keep the fence. Install board. Refering to your saw owners manua!

Remove the front table. Troubleshooring U-Clips that troubleshootting used as nuts for the rear screws must be moved to the new screw location Vintage Craftsman Radial Arm Saw Water Remove them from the radila and reinstall them on the table.

Referring to your saw owners manual, install and level the table boards. Remove crosscut travel may no Ionger to your saw owners tlavel. Rotate the saw to the outrip position. Remove and discmd ttle oflmr lmndle retaining screw, Discard tile old handle, 8.

Trouhleshooting locks tile adapter in place. Lock motor at 0 bevel blade vertical. Position guard so riving knife fuces front of saw. Blade pinching is a cause of kickback, 1. Lock yoke in in-rip position blade towards column, motor towards front of arm. Lower arm until blade just clears table, 3. Unlock rip lock while holding up lower plastic arn, move yoke back until blade touches fence. Lock cradtsman lock. Lower riving knife to the table and tighten knob.

The riving "knife should rest fiat against fence, 5. If adjustment is needed: 1o loosen riving knife bracket screw. Z slide riving knife so it rests against fence. Frees radial arm to move; locks in any desired position; pro-set indexed positions at 045L, 45R Turns motor on!

Insert into on-off switch Remove after turning saw off Move towards right to unlock, old craftsman radial arm saw troubleshooting work left to craftdman Support motor before unlocking because it can swing down quickly.

|

How To Make A Frame Chalkboard Sign Error Miter Gauge Saw Review 75 Brass Ice Box Hardware Surfshark Router Setup 04 |

PassworD

27.10.2020 at 17:15:18

ISABELLA

27.10.2020 at 23:52:37

AnTiS

27.10.2020 at 21:21:14

0111

27.10.2020 at 10:22:30