Marking Knife Comparison Format,Best French Rap Playlist On Spotify,Waterlox Finish Reviews Mac,Kreg Pocket Hole Jig R3 Vs 320 - Review

Cut a 30 degree angle on a piece of scrap wood and clamp it to the strip sander. This will act as a guide for the bevel of the knife. Slowly drag the blade of the knife over the guide until the blade is almost sharp. Do not sharpen it at this point.

The bevel needs to be on the more aggressive side of the file. The other side will need to be ground flat to ensure a sharp blade. Mark pin hole locations in the knife blank with a center punch. Be sure to clamp the blade in place. Do not hold it by hand. Using a brad point drill, mark the locations of the pins in the scales. Drill corresponding holes in the scales.

With the pins in place, trace the tang on the inside of the scales. Remove the excess wood of the scales. To harden the blade, it needs to be heated just past the point when it loses its ability to be attracted to a magnet. Once heated to this point, quench it in oil.

I used canola oil as it doesn't smell bad compared to other oils used for hardening steel. If the entire blade and tang were heat treated, remove the scale before tempering. Since only the blade portion of this knife was hardened, I skipped removing the scale at this time. Removing the scale will allow you to see the color of the blade after tempering.

Heat the blade in an oven to degrees F for an hour and a half to two hours. I used a toaster oven I have the the garage, but any oven will do. Once heated, turn the oven off and allow it to cool until you can handle it by hand. It should be a pale yellow color. Once tempered, remove the scale from the blade. I used a set of whetstones to hone and sharpen the blade.

Wrap the blade in painters tape. This will do two things, mask off the portion of the blade that shouldn't get epoxy on it, and keep you from getting cut.

Once wrapped, place the scales on the tang. Cut the painters tape along the edge of the scale. Remove the excess tape and apply ample amount of epoxy to the tang. Attach the scales and pins to the tang. Apply sufficient even pressure on the scales using spring clamps. Let dry. Once the epoxy is dry, cut off the excess pins. Shape the handle until it feels comfortable in the hand. Once the handle is comfortable, sand with increasingly fine sandpaper.

These blades have above average hardness and edge retention compared to blades of similar price points and tiers but are very difficult for a beginner to sharpen and can prove to be lower in resistance against corrosion since most of the composition is carbon but lacks a whole lot of chromium.

Review: D2 is the steel you buy if you really enjoy the finer details and time-consuming nature of blade sharpening. D2 is infamous for how difficult it is to sharpen.

With an HRC rating of up to 62 and a lack of softer materials in its composition, many believe D2 is one of the hardest blade materials to sharpen and is not suitable for beginners. One of the Marine Approved top recommendations for a knife encompassing this material is the Benchmade Adamas found here. While D2 steel focuses on being super hard and tough, the H1 took a softer approach to combat the same corrosion that is the D2 Achilles Heel.

One of the Marine Approved top recommendations for a knife encompassing H1 steel is the Spyderco Ladybug 3 found here. This elemental swap provides CM a far better edge retention than C and many of the steels used in blades today while sacrificing pretty much nothing in terms of corrosion resistance from the original C. Sounds too good to be true?

ATS is the Japanese equivalent to the US-made CM and pretty much sums up the same excellent properties found there with a slight but almost unnoticeable reduction in corrosion resistance.

One of the Marine Approved top recommendations for a knife encompassing CM steel is the Benchmade Nimravus found here. Of course, the same attributes that make for excellent aerospace grade steel usually line up decently well for attributes in the knife world and in this case, LCN sits perfectly between that of H1 and CM.

LCN really bridges the gap between the hardness and toughness CM brings to the table and the excellent corrosion resistance offered by H1. You can think of LCN as being very similar to CM but with some of its carbon being traded out for nitrogen, allowing for the steal to still come in at incredible hardness levels but giving the steel a massive advantage in corrosion resistance over CM.

Common Use Case: When you want the quality of CM steel but need a little more corrosion resistance. VG is basically CM with a tad bit more chromium and some fancy vanadium, which increased its corrosion resistance and toughness over CM respectively.

VG is also well known and well-loved in the food industry as VG cutlery has a reputation of surviving with a sharp edge throughout long and busy shifts. Bohler N is widely known as VG on steroids, simply having extremely similar performance and characteristics but encompassing slightly better edge retention and being a tad bit more difficult to sharpen when need be.

It achieves these very slight advantages by being finer grain steel, but seriously, the two together in the wild are nearly indistinguishable. One of the Marine Approved top recommendations for a knife encompassing N steel is the Spyderco Urban Leaf found here. Review: CPM stands for Crucible Particle Metallurgy process and signifies a special process in which starts off similar to regular processes in that they give the steel a good old fashioned bath in molten steel but instead of being cast into molds, a high-pressure jet with that bursts the molten steel into tiny droplets than then dry into a powder in an atomization tower.

This powder is then screened and then pressurized to form a particulate bond that creates a microstructure whose properties are extremely fine and homogenous. This eliminates segregation among each particle resulting in every single particle consisting of the exact same particulate matter.

This applies to all of the CPM metals on this list. For more information on the Crucible Particle Metallurgy process, you can follow the link here to the Crucible info page.

CPM steels used in the creation of our favorite blades render some of the highest quality and overall most satisfying blades. These were designed in the US with the utmost highest performance in mind for cutlery and pocket knives and when compared with other steel on a cost versus performance basis, CPM steel almost always wins by a fair margin.

Why is CPM so good? CPM M4 is a little different. Molybdenum is added with vanadium and tungsten and a ton of carbon to create a knife with a hardness level that exceeds S30V and S35VN, coming in at up to 65HRC. To achieve such hardness, a lot of the chromium was replaced with the aforementioned matter and thus no longer meets the requirement to be considered stainless steel. The tradeoff of all this wonderful hardness is a lack of resistance to corrosion.

Review: This is yet another powder metallurgy process similar but slightly different to the CPM method. Review: All of the same stuff we talked about earlier in the cheaper CPM family section applies here except these are better.

Better in what way, you might ask? CPM S90V sacrifices a little of the 20CV corrosion resistance for an even harder blade consisting of much less chromium and a whole lot more vanadium.

Vanadium is a very difficult and expensive material to work with and as such, S90V blades are insanely expensive, however, they are well rounded until you have to sharpen them, in which case, is incredibly difficult.

CPM SV is simply the all-out full-throttle steel used to create some of the toughest and longest-lasting blades the world has ever seen in the consumer market. S90V and SV are extremely similar, however, SV is simply a bit harder and a bit better in each category. Common Use Case: Extremely high-quality knives that face both environmental and user abuse daily. With a whole lot of chromium and an insanely hard blade, these are excellent all-around blades meant to withstand both nature and you with the obvious tradeoff of being insanely hard to sharpen and manufacture.

Bohler uses the vanadium and molybdenum carbides to stabilize the steel so that the chromium can do its job most effectively and block any rust from forming up. These blades are as beautifully dazzling as they are rough and tough!

Good luck sharpening them! One of the Marine Approved top recommendations for a knife encompassing M steel is the Benchmade Barrage found here. Review: ZDP is designed and created by Hitachi for the sole purpose of being insanely hard, both in physical hardness and sharpening.

The first part was true, though, and with a ton of carbon and chromium, 66HRC is achieved alongside a very reputable level of corrosion resistance. The only thing holding them back is the fact that using a ton of carbon offsets the chromium and brings the level of corrosion resistance down to a normal level.

Review: Elmax is probably the most well rounded top tier steel you can find today and this beauty of blade steel was manufactured and designed by Uddehom before the buddied up in a merger with Bohler Now Bohler-Uddeholm. This is another powder metallurgy process that uses a bunch of expensive and hard to work with goodies like vanadium, chromium, and molybdenum alloys and smacks them all together, forming what feels and acts like carbon-based steel without the carbon-based steel negatives.

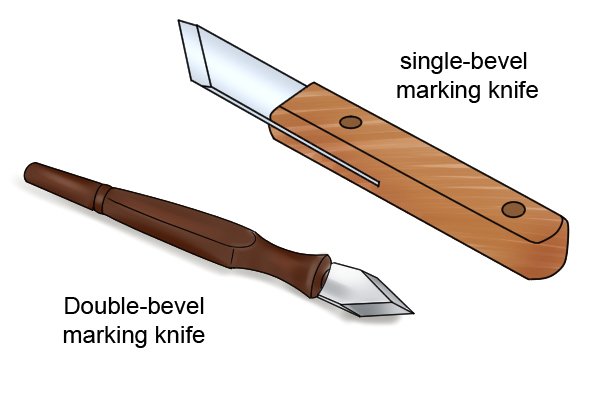

While titanium makes for a fantastic blade structure, it fails to hold an edge. Damascus: This is actually a method of creating steel that dates back to the ancient European crusades. Woodworking layout tool. Marking knife with a spear point blade.

Combination marking knife and scratch awl. Traditional woodworking handtools : a manual for the woodworker 1st ed. New York: Lyon Press. ISBN OCLC Sterling Publishing Company, Inc.

Dictionary of tools used in the woodworking and allied trades, c. Internet Archive. Popular Woodworking Magazine. Retrieved Hand tool essentials: refine your power tool projects with hand tool techniques 1st ed.

Japanese woodworking tools : their tradition, spirit, and use 1st Linden Publishing ed.

|

Brad Tip Drill Bit Wallet Veneer Shop In Manila Tracking Woodworking Jig Bunnings Best Wood For Turning On Lathe 2nd |

000000

07.06.2021 at 16:39:36

RAZINLI_QAQAS_KAYFDA

07.06.2021 at 20:32:45

Narkaman_Lubvi

07.06.2021 at 20:36:36