Lathe Turning Tools Explained 12,Pumpkin Carving Kit Home Bargains 8th,Soft Close Drawer Slides Not Working Utility,Makita Dtm51zjx7 18v Multi Tool Cordless On - Review

lathe-turning-tools-explained-12

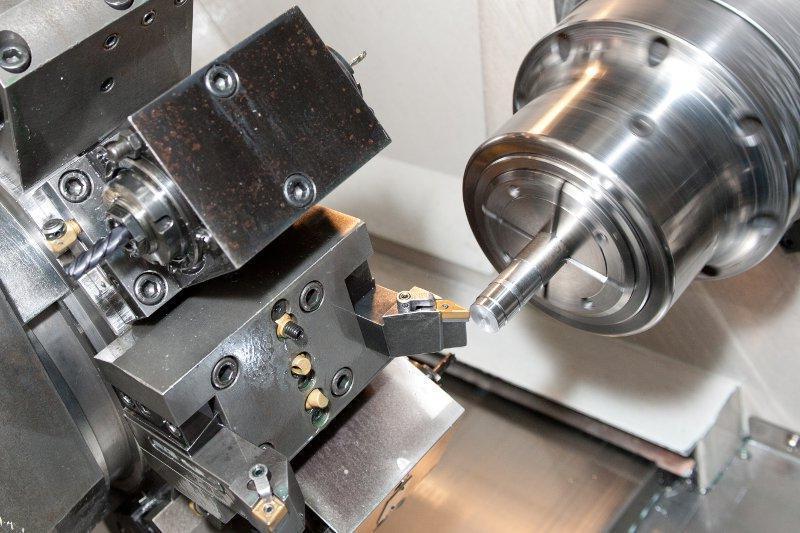

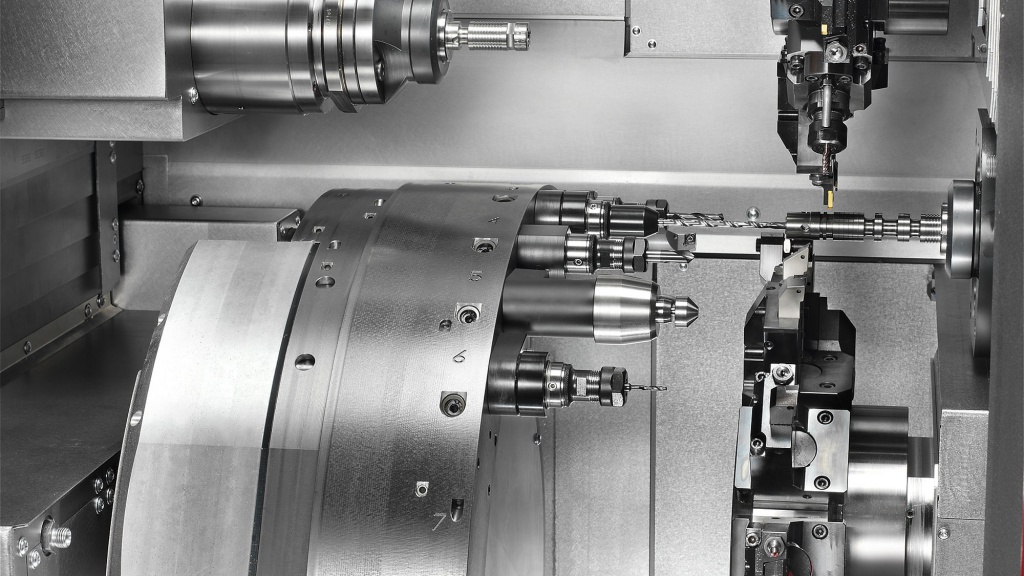

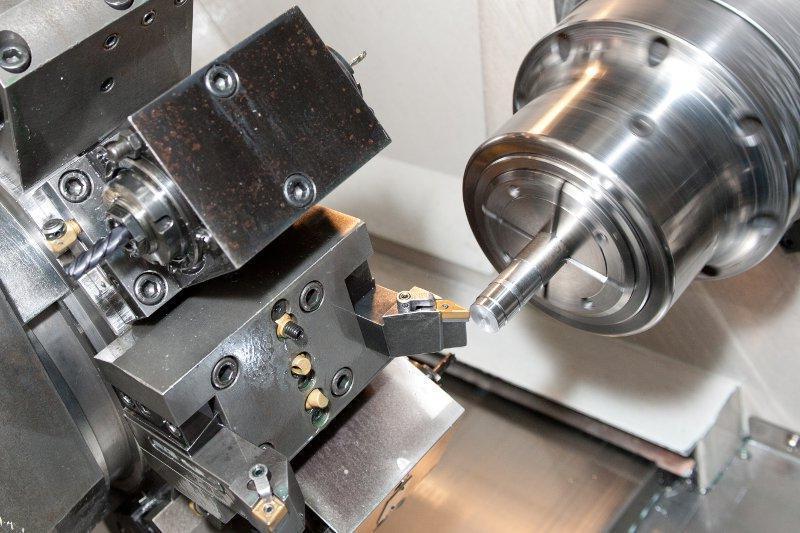

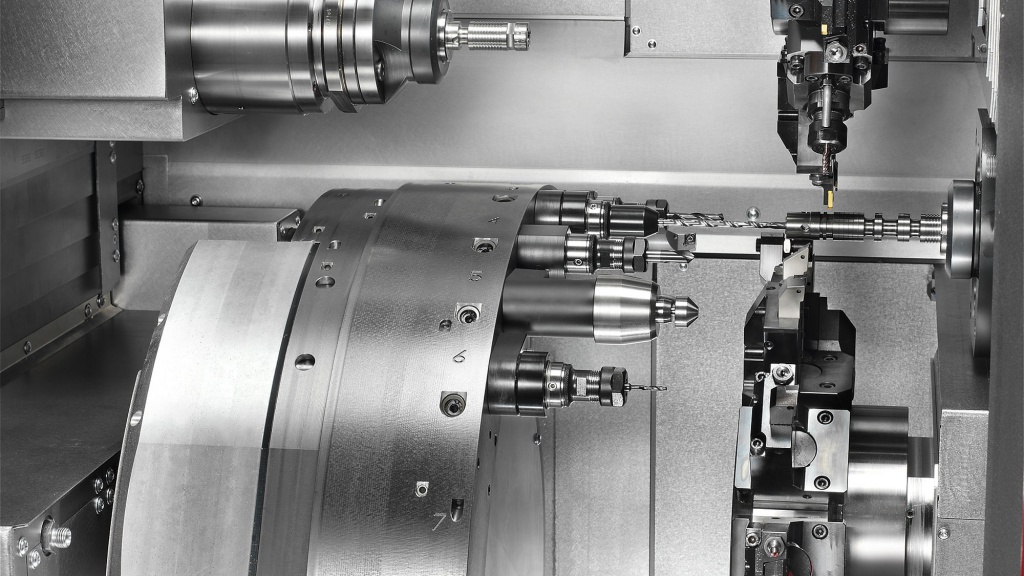

Lathe cutting tools are used to perform different operations in lathe. The tools are Turning tool, Chamfering tool, Boring tool, thread cutting tool. The work is held and rotated on its axis while the cutting tool is advanced along The lathe is one of the most versatile machine tools used in industry. Never run the machine faster than the recommended speed for the specific material. The variety of cutting tools available for modern CNC turning centers makes it imperative for machine operators to be familiar with different tool geometries and how they are applied to then mounted on the lathe turret. Example: 12 = 1/8” x 1/2". Important: The depth-of-cut for roughing should never exceed 1/2 the.

An ordinary lathe turning tool may sever the purpose where a copying attachment is used to reproduce the form of a template. The fingernail, or swept back, gouge. When you are happy that your tool rest is at the right height for you and at a distance appropriate for the blank, you should be ready to work. No gimmicks, just wood chips. Out of these cookies, some are categorized as essential for the working of basic functionalities of our websites. Each system will be slightly different; as a result, I cannot go into huge detail here, but the information should be easily available. Make sure you turn the lathe off before using the saw.

|

How To Make A Frame Without Wood Wall Pumpkin Carving Kit Morrisons Co |

Seytan_qiz

18.11.2020 at 13:37:27

Inaplanetyanka

18.11.2020 at 22:51:10

GULYA

18.11.2020 at 22:31:40

Lala

18.11.2020 at 12:19:35