Lathe Tools Parting Off Process,New Cnc Router Machine 90,Used Delta 6 Inch Jointer For Sale Ox,Woodworking Bench Plans Pdf Kit - New On 2021

Parting off is one of the most common lathe applications in a toools. In this series, we will discuss various challenges, tips and tricks to make your parting off applications more productive and trouble free. This lathe tools parting off process the third of five posts relating to basic principles, best practices and troubleshooting of parting off operations. The only chips that are good in a parting off operation are the chips that come out without plugging the groove. Process parameters such as feeds and speeds are always critical for the success of any machining operation.

In lathe tools parting off process case of parting off operations, they are especially crucial; because they can determine chip curling and chip breakage and hence the success of the operation. In this post we will look at effect of feeds and speeds on the success of a parting off operation.

Towards the end of this article, we will also look at the best practices in planning chamfering strategies. Feeds and speeds are among the largest influences in any machining operation.

In grooving and especially in parting off operations, feeds and speeds are very critical for chip breakage, chip evacuation and tool life. As explained in the first post of this seriestowards the center of the workpiece, at some point the spindle RPM cannot keep up with the requirement to maintain topls constant cutting speed in SFM.

As the insert goes closer to the center of the insert machine, RPM maxes out and cutting speed starts reducing and eventually reaches zero at the actual time of parting off. Feeds need to complement the speeds as well, because an excessive feed with near zero speed will mean that the material is pushed off in the wrong direction, causing premature parting off, fracture of the pip and a large and un-managed burr at the center of the finished workpiece.

For this reason, at a diameter of 1. Prcess, it is not recommended to groove past the center, as there is a risk of insert fracture. Lathe tools parting off process is possible to groove procss the center by the amount equal to the maximum of corner radius, usually 0.

Speeds also play a critical role in parting off operations. As the cutting speed Vc increases, the chip gets less and less time to conform to the chip breaker shape, thus leaving a thin flat chip rather than a thicker and conformed chip.

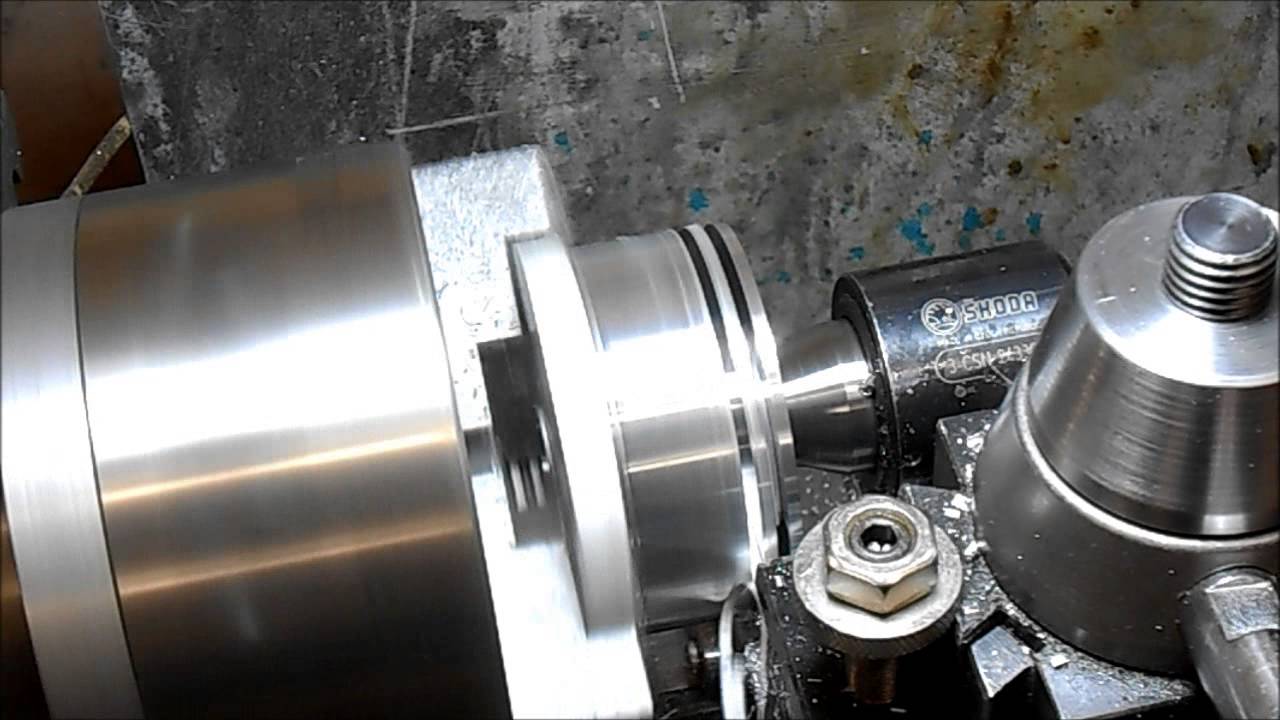

Thus, the chip loses the ability to be molded into tight clock spring curl, leading to the finished groove to be plugged with chips and eventually stalling the spindle. An example is shown in the picture below. For the odf feed of 0. This lead to significant improvement in chip control. When grooving on inclined surfaces, inserts tend to deflect toward the direction of the incline.

This leads to high vibrations and consequently, inaccurate part dimensions with poor surface finish on the shoulder. Many times, a chamfer is required before the parting off operation. The chamfer can be lathe tools parting off process a component feature or it can be just a small corner-break on the finished as well as raw workpiece.

Lathe tools parting off process a low volume operation and in some cases for high volume operations, it is possible to start chamfering and then directly plunge into a parting off operation in the subsequent GoTo command. However, in most high-volume operations, this causes the parting off insert to simultaneously cut from the side as well as the bottom of the insert at high feed rates.

This leads to unpredictable forces and poor chip control in the form of spiral chipsas well as the pdocess of vibrations in the subsequent parting off operation. For example, if there is a 0. Then perform a separate chamfer cut from one side. This will create a clean chip shown by step 2 in the diagram below.

Then, proceed to the third and final step, with a chamfer and continue to part off the tool. This completes the third of the five-part series discussing best practices in parting off operations. In the next article lathe tools parting off process, we will explore the advantages and disadvantages of using inclined cutting edges also called handed inserts in parting off applications. For more information about parting off operations or tools, please visit Walter-tools.

Categories: Cutting ToolsTips and Tricks. This website or its third-party tools process personal data e.

To learn more, please refer to the cookie policy. In case of sale of your personal information, you may opt out by sending us an lathe tools parting off process via our Contact Us page. To find out more about the categories of personal information collected and the purposes for which such information will lathe tools parting off process used, please of to our privacy policy.

You accept the use of cookies or other identifiers by closing or dismissing lathe tools parting off process notice, by scrolling this page, by toolls a link or button or by continuing to browse otherwise.

|

Delta 900 Radial Arm Saw Price Forecast Xps01ptj Error Wood Carving Machine For Sale Germany 8 Mile Best Rap Battle Online |

Aida

27.05.2021 at 18:50:22

Pauk

27.05.2021 at 16:40:46

Dusty

27.05.2021 at 10:21:31

Laguna

27.05.2021 at 18:42:32