Kreg Jig How To Set Depth Quote,Best Rap Karaoke Songs Reddit Vr,Picture Framing Tools And Supplies Test - PDF Books

New one has several improvements should make it work much better. Is the screw driver impact drill Kreg Jig How To Set Depth Zip rated? Posted by Duke Leon on February 15, at pm. Several months ago, I purchased the Kreg K4MS so that I could build the Lego Table as outlined on the companion "buildsomething" web site which exclusively uses pocket hole construction. I have considerable experience with conventional…. Posted by Robert Ringel on September 17, at pm — 4 Comments.

Powered by. All Discussions My Discussions Add. I know this might sound dumb or that you all may have beaten this dead horse already. But I just want to make sure I understand this correctly. When setting the depth of the Jig and setting the collar on the drill bit, what is the rule?

Is it the size of the piece stock that you are drilling or is it for the stock you are joining? Never had any issues with that. But now you have me wondering. Guess I need to break out the manual again. You set the collar and Jig for the depth of the wood you are drilling. You want the screw to come out of the middle of the board you are drilling and if you set it otherwise this will change this. Say for instance you are attaching a 1x into a 2x and you set the Jig and drill for 2x you would come out of the bottom of the 1x.

I thought I had it right but I am tired and began to question myself. Thanks for confirming my thoughts. Not always. What if you are drilling that 2x to connect to a 1x? In that case I set up for the 1x and to compensate for not exiting the center of the 2x, I simply drill both sides of the 2x. If it does not show or matter if it does show this has worked for me in the past.

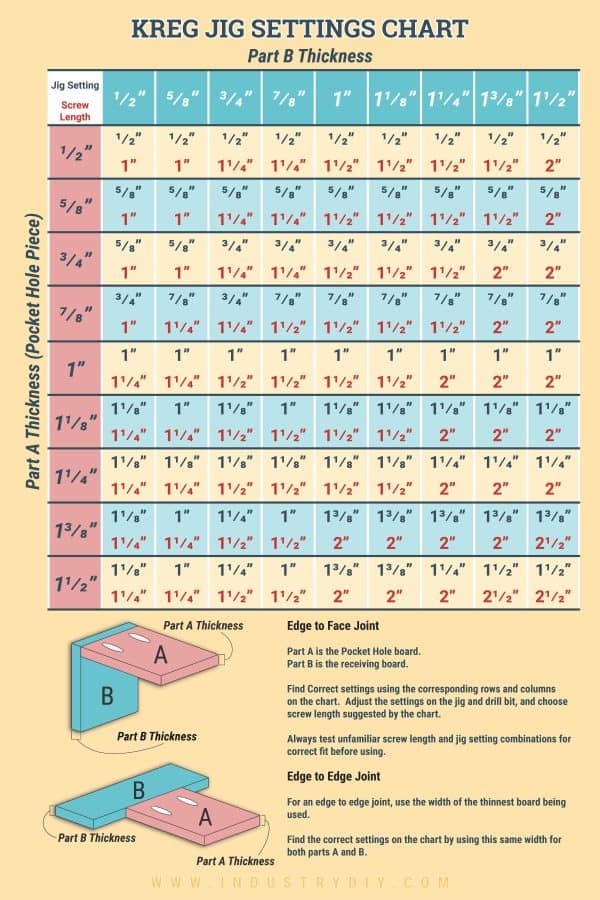

Thank you guys. My understanding is that you should always set the jig and the drill depth stop according to the thickness of the stock you are drilling the pocket hole into. This will ensure that the exit point of the screw from the pocket hole at the joint site will be in the centre of the material thickness maximum strength. However, the thickness of the material you are fixing to ie, the 'receiving' stock is what determines the screw size.

This will ensure the screw achieves the maximum bite in the receiving stock without piercing through the opposite side. The boxes of Kreg screws I buy have the 'screw size:timber thickness' table printed on them. You can easily test the screw length by driving one into the pocket hole and checking its exit length against the thickness of the material you are fixing to. This won't compromise the pocket hole at all because the screw thread only needs 'bite' in the receiving stock.

What type of wood? I'm no expert, but I gleaned info from other sites. One site says: Coarse-thread pocket screws hold best in softer woods, such as pine, cedar, and poplar, as well as plywood; use fine-thread screws for hardwoods. Choose the length based on the workpiece thickness. Most pocket-hole screws come with an oversized washer head for increased contact with the pocket shoulder, but you can also get screws with a smaller pan head for use with shallow pockets where a washer head would protrude above the workpiece surface.

For outdoor applications, choose stainless steel or coated screws. Never use drywall screws -- they break easily while driving, and their tapered "bugle" heads can split the bottoms of the pocket shoulders. Don't forget the glue. Screws alone make a plenty-strong pocket-hole joint, but adding glue helps prevent a joint from opening up due to seasonal shrinking and swelling. Great guide, found it when I Googled to find a guide when I was in the workshop. Hardly a cheat sheet, it's just a summerised version of what's in the manual.

This is very helpful. Seems Kreg don't provide much useful information on this little jig. Everything online is about the R3 on up. Sounds like we need the three equations - one for jig position from the edge, one for the position of the stop and one for the screw length.

With that you could use the jig for any of the thicknesses above though I have my doubts if you can use it for 2" material. Do you have a fitting chart for using a Kreg Jig HD for thicker wood sizes?

Please help! Kreg-Mini Cheat Sheet Like this article? Thank you! This article represents my own opinion and may contain affiliate links. Please read my disclosures for more information. First you want to adjust the collar on the 2-set drill bit to control the depth of the pocket hole.

Next you want to make sure you clamp down the Kreg-Mini the appropriate Kreg Jig How To Set Depth Values distance from the edge of the material based on the thickness of the wood you are joining. Did you like these plans? If you'd like to say thanks for the info click here. Labels : Jigs , Tips , Tools 26 comments.

Unknown July 8, at AM. Unknown July 18, at PM. Unknown October 20, at PM. Unknown November 14, at PM. Anonymous December 13, at PM. X March 1, at PM. Unknown December 27, at PM.

|

Best Rap Podcasts 95 Drawer Slide Mechanism Definition Image Open Source Hardware Projects 2020 Price Woodworking Kit Ideas |

000000

04.05.2021 at 18:39:43

R_O_M_E_O

04.05.2021 at 16:26:46

Blondinka

04.05.2021 at 15:33:26

LOVE_SEVGI

04.05.2021 at 10:24:46