Jet Air Filtration System Australia Usa,Hand Plane Brands Quotes,Wood Projects Cricut Maker 90 - Plans Download

T Petrol Soff-Cut 97 Easy and efficient filter cleaning Easy and intuitive controls Efficient filtration system Clean and simple bag change. S 36 Propane 80 S 36 66 Efficient filtration system Easy and efficient filter cleaning Durable design Easy to transport.

S 26 66 S 13 66 S 11 46 Container capacity. High productivity Excellent mobility Efficient filtration system Auxiliary outlet. DC 62 DC 19 Efficient dust containment Efficient vacuum units Robust machine Comprehensively tried and tested. HTC D80 83 HTC D60 83 C 66 Durable design Increased productivity Clean and simple bag change.

Durable design Easy to transport Increased productivity Clean and simple bag change. Slurry vacuums. W P 70 Renowned durability Reliable overfill shut-off High pumping pressure Integral stainless steel strainer. W 70 P 66 Renowned durability Reliable overfill shut-off Extreme pumping pressure Easy to transport. W 70 70 Renowned durability Reliable overfill shut-off Easy to transport Multipurpose use.

Air scrubbers. A 66 A 67 Compare products. Recommended work methods for safe and efficient dust control. One of the best ways to control dust is by using water. A slurry collector can be attached to a slurry vac to keep the workplace clean. This device should be connected to a dust extractor with the appropriate airflow and capacity for the application and also equipped with HEPA filters. When cleaning the work area, use a scraper instead of a broom to sweep the floor.

Always use a dust extractor equipped with HEPA filters when vacuum-cleaning. Wet drilling The slurry collector connected to a slurry vac keeps the workplace clean. Dry drilling A dust extractor with the appropriate airflow and capacity for the application, also equipped with HEPA filters, takes care of the dust. Handling the smallest dust particles is the biggest challenge. Dust particles hovering in the air at construction sites contain a number of different substances. Some of them can be harmful or irritating if inhaled, such as asbestos fibres, crystalline silica, mold,, soot, PCB and certain microbes.

Dust from cutting, drilling or grinding concrete, brick and similar building materials contain crystalline silica, which is hazardous when very small respirable particles are inhaled. These respirable dust particles can penetrate deep into the lungs and cause disabling and sometimes fatal lung diseases.

These respirable dust particles are so small that they can hover in the air for hours, invisible to the naked eye. Using high-quality professional dust control equipment, along with personal protective equipment that is efficient enough to catch even the smallest silica particles are some of the best ways to handle dust. Governmental rules and regulations. Since respirable dust can be a threat to occupational health, most countries have implemented rules and regulations for permittable exposure limits.

These regulations vary from country to country. Consult your local authorities for more information. This standard requires employers to limit worker exposures to respirable crystalline silica and to take steps to protect workers. The standard provides flexible alternatives, especially useful for small businesses. Small entity compliance guide. What is table 1? Table 1 matches common construction tasks like concrete cutting, drilling, and grinding with recommended dust control methods, therefore employers know exactly what they need to do to limit worker exposure to silica.

For wet applications, Table 1 typically specifies equipment with an integrated water delivery system for continuous water feed to the cutting tool. In some operations, respirators may also be needed.

Designate a competent person to implement the written exposure control plan. Restrict housekeeping practices that expose workers to silica where feasible alternatives are available. Offer medical exams — including chest X-rays and lung function tests — every three years for workers who are required by the standard to wear a respirator for 30 or more days per year.

Train workers on work operations that result in silica exposure and ways to limit exposure. Complete systems including best-in-class dust and slurry management. With Husqvarna, you get access to guidance, knowledge and a broad range of powerful equipment and diamond tools for almost any type of job, all available in one place.

You get a choice of systems designed around you, to help you work smarter and finish any job as quickly, efficiently and profitably as possible. Our complete offering also includes a fully integrated range of highly efficient equipment for dust and slurry management, enabling you to comply with any rules and regulations without compromising your productivity. By combining our expertise in concrete cutting, drilling and grinding with the foremost Jet Air Filtration System Model Afs 2000 Gen technology in dust and slurry management, Husqvarna has a unique ability to provide you with easy-to-use solutions.

Handling the dust and slurry more efficiently means a better way of working. Husqvarna T-line. The Husqvarna T-line is developed for large-scale projects that demand substantial dust extraction. The machines can deal with materials that are difficult to handle, such as grinding dust and demolition materials in a wide variety of applications.

The powerful motors deliver airflow efficiently for all types of floor grinding machines as well as for local or central vacuum systems in construction work. The heavy-duty filter system collects the dust in three separate stages, from the heaviest to the finest dust particles, providing a large collecting capacity and a long filter life.

Individually tested and certified HEPA filters required for respirable silica dust are fitted as standard. Husqvarna W-line. High performance slurry vacuums. The Husqvarna W-Line of slurry vacs are designed for the toughest jobs a slurry vacuum cleaner can handle. The renowned quality, durability, efficiency and long, trouble-free service life has earned the W-Line the status of a modern classic.

By using high quality stainless steel components, a unique combination of 3-stage filter system and a large-volume slurry float together with well-considered pump solutions, the W-line delivers uninterrupted, high capacity slurry evacuation all day long. W-Line can also handle occasional collecting of dry dust and can be equipped with an optional HEPA filter. Husqvarna S-line. Single-phase hepa dust extractors.

The Husqvarna S-line consists of professional dust extractors designed to meet strict demands. These compact, lightweight machines are equipped with one, two or three powerful single-phase electric motors with separate cooling, capable of running continuously all workday. This makes them suitable for all construction, abatement and restoration jobs, as well as electric power tools.

The Jet Pulse cleaning of the conical main filter ensures that the dust is continuously collected throughout a full work day. All of the machines have been designed specifically for HEPA filters which are individually tested and certified.

This results in superior and safe dust collection, even on fine sanding and gypsum dust. Husqvarna A-line.

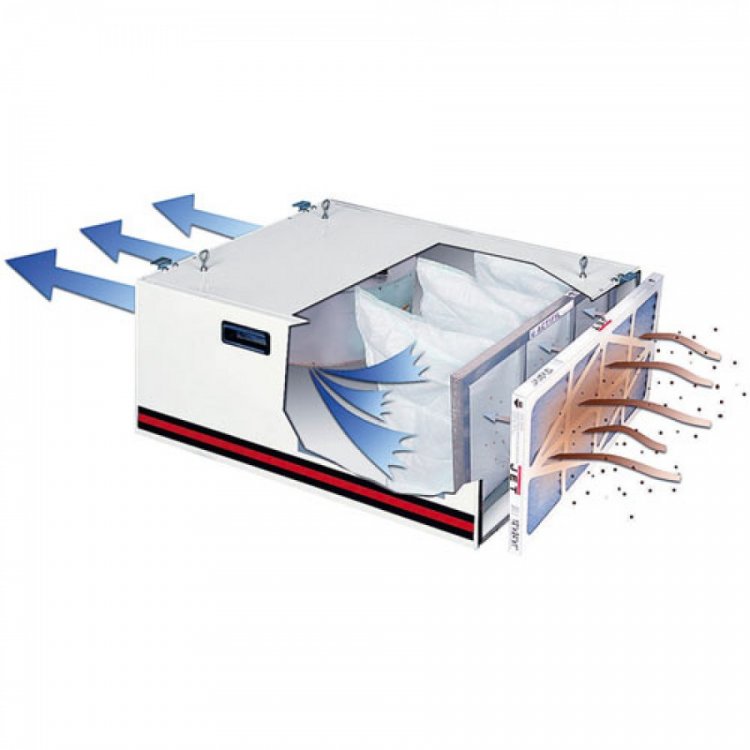

The Husqvarna A-line includes some of the most advanced portable air scrubbers available on the market. They are tested and certified for use as both Air Scrubbers and Negative Air Machines, making them the ideal complement to your dust and slurry management equipment.

They provide added workplace safety and aid in legal compliance. The compact design makes the units easy to move and transport.

Due to the safe filter system and a design that is perfectly matched to operation with HEPA filters, these air cleaners put out ISO 5 Class Air, providing superior air quality — no matter if dealing with concrete dust, fine sanding dust or gypsum dust. Fast and correct service and repairs are essential for professional users. To make the service process smooth and seamless, all authorized Husqvarna service and parts staff have access to an on-line Service Tool, which supports all service and repair functions, enabling shorter lead times and higher service quality.

Surface preparation user guide. Go to guide. We make drilling specialists more efficient. Alternatively, you can view our range and shop online. About Equipco — Leading Fuel Equipment Specialists As one of the best fuel equipment suppliers and distributors in Australia, you can rely on Equipco when you need fuel handling equipment specially made for industry use. Discover a Comprehensive Range of Fuel Handling Equipment Whether you need fuel dispensing equipment or fuel storage solutions, we have no shortage of options for sale to choose from.

Browse our range of fuel handling equipment online to discover: Fuel transfer equipment Fuel storage tanks Fuel tank fittings Fuel management systems Filters for tanks or pumps Level gauges Diesel equipment Petrol equipment Oil equipment Grease equipment Adblue equipment Aviation equipment Why Buy from Equipco? Read More. Date: 13 Dec The plastic moulde Read Full Story.

Date: 15 Oct Australian Standards set out the guidelines and regulations to be followed for safe sto I ordered a part from you online. It was despatched that day and I received it next day. I would just like to say thank you. It is refreshing I wanted to give you some statistical feedback on the savings our business has made since we investe Firstly, thank you for your terrific service; it has been a pleasure to deal with you throughout our time working with Equipco.

|

Best Rap Battle Lyrics Music Wood Projects Using Tree Stumps New |

Rashad

04.08.2020 at 21:48:17

Romantic_Essek

04.08.2020 at 12:17:48

anceli

04.08.2020 at 16:52:36

PoranoiA

04.08.2020 at 13:32:13