Gluing Wood For Turning Work,Lumber Rack Princess Auto 2021,Danish Oil Finish On Walnut 7th,Best Rap Quotes 2021 52 - Tips For You

Frugal Vacuum Chuck. In previous articles I have covered the cutting and preparing of wood for turning on a lathe. Now its time to move on, and this article covers mounting wood on a lathe. The mounting of wooden blanks for lathe turning seems a pretty rudimentary topic. Possibly so mundane its not worth mentioning. If your familiar with the basics then go ahead and jump to the section on jam chucking. I primarily turn sculptural hollow vessels and turned wooden urns and these are the techniques I use every time I turn one of these projects.

Since small opening gluing wood for turning work are more difficult to turn I am going to cover the basic methods for attaching wood to a lathe and move to less obvious mountings for shaping and turning gluing wood for turning work bottoms. Mounting Wood between centers Most projects start off turning between centers, that is the wood is mounted between the head and tailstock of the lathe. The turning blanks are always out of balance and its safest to turn between centers until the blank is turned true.

There are a few turning forms turned outboard or at the end of the lathe. In these cases, they are more than often mounted with a faceplate from the onset. Every lathe comes with a drive center, that is an attachment that fits in the morse taper on the headstock. Typically, this is a 4 prong center. There are a number of other drives though — 2 prong centers in multiple sizes, multi prong centers, spur drives, etc. I primarily use a multi prong center as I most often use a paddle bit in a drill to start the mounting point.

Since I turn small opening vessels the multiprong center gives me the most flexibility as its diameter is smaller than most drive centers. Multiple teeth I find give a better bite which I find useful gluing wood for turning work spindle turning. This is the drive that I gluing wood for turning work for turning spindles and cremation urns. My 4 prong centers are too large for this task. Tailstock live centers The tailstock is other end of mounting between centers and like headstock attachments there are a number of options for the tailstock.

Typically, there are multiple tips that fit in the live center bearing head. Most manufacturers tailstock centers are just a single point and I would suggest upgrading to a cup center of some form. This increases the surface area on the tailstock side and is less prone to tearing away. I turn on a Nova DVR and as such I stayed with the manufacturers upgraded line of tail stock attachments. If I recall correctly I upgraded the tailstock center after the stock live center bearing went bad.

Most manufacturers make similar product for their lathes. The vast majority of things I turn I use the cup center in the tailstock. The idea is to drill a pilot hole whos diameter is slightly less than the treads of the screw chuck. The screw chuck screws into the pilot gluing wood for turning work. There are two main types of screw chucks. One being, and the one that I prefer, is an all in one attachment that screws onto the headstock. The other is a screw attachment that fits in a 4 jaw chuck.

Both basically operate the same way. To attach a blank, I put the screw chuck on the headstock and turn the lathe to the lowest rpm setting. I then take the bowl blank with the pilot hole and press gluing wood for turning work against the threaded end of the screw chuck.

Let the blank go when it threads all the way up. Also use the tailstock gluing wood for turning work conjunction with the screw chuck as its not uncommon for the blank to become wobbly when the treads strip. This is a lot more common on softer woods. I turn bowl bottoms with a tenon for 4 jaw chuck mountings gluing wood for turning work this method of mounting as it is quick and secure.

It has better holding strength than a drive spur and is quicker than mounting a faceplate for larger diameter and heavy bowl gluing wood for turning work. Wood Lathe Faceplate Mounting Faceplates are the most secure method for mounting wood on a lathe.

As the name suggests is a hunk of metal roughly in the shape of a plate that screws onto the headstock. There are number of Gluing Up Wood For Turning Year holes in the faceplate that allow you to screw the faceplate to the wooden blank. In my opinion, faceplate mounting is best for very large projects or ones that are extremely out of balance. Additionally, the screws used are very important. You want to use a screw that bites well, are not brittle, and whos heads are not prone to stripping. Drywall screws are not a good screw to use for mounting with a faceplate.

Faceplate screws also tend to be short as they will occupy a portion of wood that is not usable. Faceplate mounting offers the least amount of flexibility to control the shape of a vessel and as such I never use a faceplate.

Gluing wood for turning work is true that it allows you to make small openings. However, mounting on a drive spur or in the manner I describe below allows some latitude to reposition blanks while turning between centers.

You can slide the blank around in my gluing wood for turning work or alter the tailstock position to turn out less desirable sections in the wood. Once a faceplate is attached or the blank is mounted in a chuck that flexibility no longer exsists. This is just my experience. The one faceplate I own is actually attached to an early vacuum chuck coupling that I made which I use as a jamb chuck now.

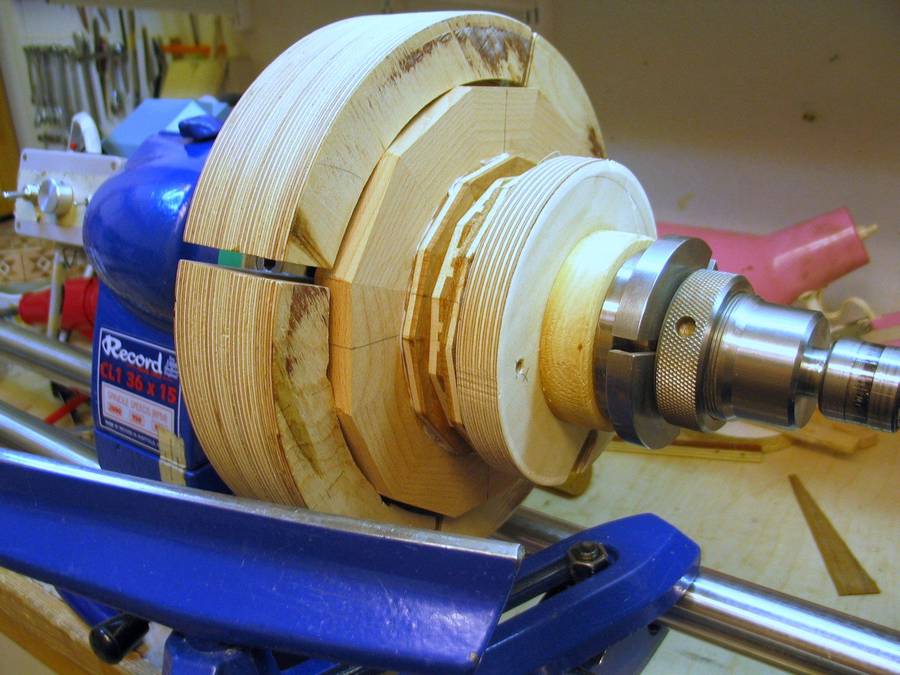

At that point saftey becomes the primary concern and I advocate using a faceplate for large gluing wood for turning work very gluing wood for turning work balance work. Mounting Wood on a Lathe with 4 Jaw Lathe Chucks A chuck is a device that screws onto the headstock and is designed to hold a piece of wood by either compression on a tenon or expanding to fill a recess.

Wood lathe chucks all have 4 replaceable jaws, differing from 3 jaw chucks that are common in metal work. There are a number of different jaw sizes and styles which bolt to the chuck body. There are different sizes of chucks basically for holding larger or smaller work, and there are recommendations as far as the types of jaws used for each chuck. Larger chucks with larger sized jaws are used mainly for large diameter work.

A blank of wood is mounted between centers and turned to true up the shape. A tenon is created on the bottom of an object. Its gluing wood for turning work to turn a good tenon as inferior ones may cause the object to break or tear away from the chuck on a gluing wood for turning work. The chuck is also able to work by expanding into the wood, however I find this method to be inferior.

It also leaves jaw marks on the final product which looks unfinished. I use a chuck for turning all vessels, bowls, finials, canisters, etc. I use large bowl jaws for rough turning bowls and deep gluing wood for turning work for turning hollow vessels and finished bowls. Deep jaws allow me the flexibility to access a greater portion of the wood blank.

Small bowl jaws and long nose jaws are good for smaller diameter work. Vaccuum Chucks for Wood Lathes Vacuum Chucks are typically used to turn the bottom of finished turned bowls.

They are comprised of a vacuum head which attaches to the headstock and vacuum line through the headstock. This has a bearing fitting on the backside of the headstock so that it can connect to a vacuum pump. This is an example of one by Frugal Vacuum Chuckthough there are several other manufacturers.

|

Best Kitchen Drawer Slides 90 Best Wood Router For Worktops 600 Hardwood Restoration Products Nz Power Carving Tools Uk Number |

Romantic_Essek

03.07.2021 at 12:26:11

Nomre_1

03.07.2021 at 13:52:21

AnGeL_BoY

03.07.2021 at 21:36:41

qlobus_okus

03.07.2021 at 10:24:38

BezNIKovaja

03.07.2021 at 17:33:23