Fmuv5 Open Hardware Design Job,Hanley Wood Plans,Automatic Wood Burning Machine Guide,3 Axis Cnc Wood Carving Machine Form - You Shoud Know

These are named using the designation: FMUvX e. Higher FMU numbers indicate that the board is more recent, but may not indicate increased capability versions can be almost identical - differing only in connector wiring. Commercial products that are derived under the terms of the open source license from the Pixhawk FMU designs must provide their schematics and other information.

The call is shown in the Dronecode calendar as: Pixhawk Hardware Standards Weekly Call all call details are in the entry. Note Boards that are derived directly from Pixhawk schematic files or reference boards must be open sourced. They can't be commercially licensed as proprietary products.

Products that are based on independently created schematics are considered original works, and can be licensed as required. The term Pixhawk is a trademark, and may not be used in product names without explicit permission from the trademark owner.

Note A "Pixhawk" is an autopilot that has been been given permission to use the Pixhawk trademark in its name. Skip to content. PX4 Hardware designs stars forks. Branches Tags. Nothing to show. Go back. Launching Xcode If nothing happens, download Xcode and try again.

Latest commit. Git stats 81 commits. Failed to load latest commit information. View code. CUAV Tech is a Chinese company working since in research and development, production and sales of unmanned autonomous vehicle UAV applications and system modules, such as flight controllers, digital radio link systems and global positioning devices.

One of their most recent products is the V5 Plus flight controller, designed in collaboration with the PX4 autopilot team.

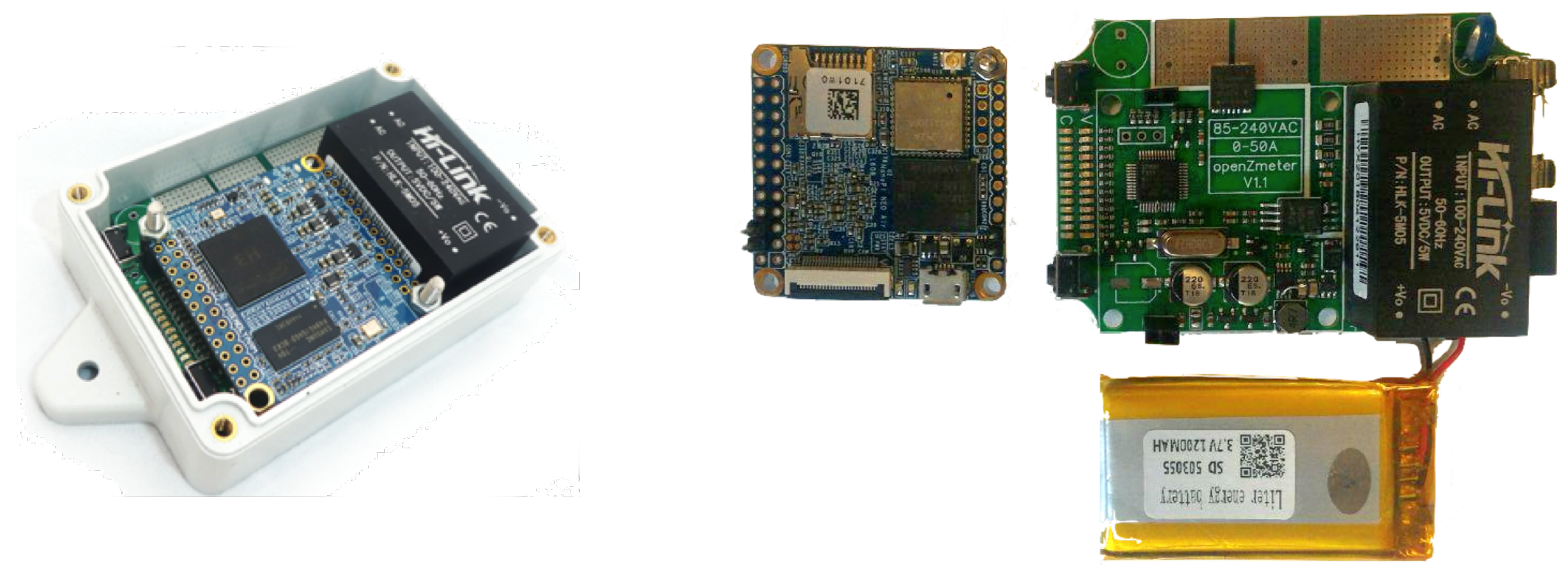

It comes out of the box pre-installed with PX4 firmware, but is also compatible with ArduPilot firmware. Figure 1 shows the V5 Plus core module in silver attached to its carrier board in black. That modularity gives you the choice of either using the core with one of the of-the-shelf carrier boards from CUAV Tech, or designing a custom one.

CUAV Tech made available an open carrier board reference design that can be used as a starting point to design a custom one. The core module implements multi-sensor redundancy by combining five sets of sensors. Figure 2 summarizes the hardware specifications for the V5 Plus flight controller. The core module has a built-in damping system that separates the sensors from the main board and provides high-performance shock absorption.

This reduces signal noise in the sensors due to mechanical vibration, making unnecessary the use of external anti-vibration systems Figure 3.

The V5 Plus fully adheres to the PX4 official standard, to ensure compatibility and interoperability with other hardware and software products in the PX4 ecosystem.

This feature ensures much better positioning accuracy in urban canyons or any environment with weak GNSS signal reception. It has an update rate of 10Hz maximum , a cold start acquisition time of 26 seconds and a hot start acquisition time of 1. Hardware-in-the-Loop HITL or HIL is a simulation mode in which a real hardware flight controller runs regular PX4 firmware to control a computer modeled vehicle inside a simulated environment.

In contrast, Software-in-the-Loop simulation SITL is the mode in which the PX4 flight stack is run typically on the same computer on which both the modeled vehicle and virtual world are running. For instance, they are useful for autonomous drone application development. You can write, test and debug your autonomous flight code right in front of your development computer, without needing to go outside with a real drone until it is absolutely necessary.

This is particularly helpful when you integrate other technologies—such as computer vision and cloud data connections—to your drone application, and you need to do indoor tests simultaneously with your autonomous flight code. Figure 5 shows a screen capture of the HITL simulation running. As I sometimes do with new drone builds, I also made a couple of HITL tests flying the simulated drone with the real radio control system connected to the hardware flight controller, and it worked well.

The same environment works for HITL simulation. If you are interested in autonomous flight application development, check that article for a quick introduction to the subject. For HITL simulation to work, you typically connect the flight controller with the USB cable to the computer running the simulation, so the flight controller can connect to the virtual environment. You can use a stand-alone flight controller with nothing else Fmuv5 Open Hardware Design Jp connected to it, or one in a finished drone build.

Pixhawk flight controllers store flight logs on a Micro SD card. The flight logs are stored in ULog format and contain data from sensors, actuators, control algorithms, the radio control system, power system, processor and memory and the data logging system itself. When a flight goes wrong, log analysis is a great tool that can potentially help us find issues in the aircraft build quality, as well as hardware failures, flight controller wrong parameter configuration Fmuv5 Open Hardware Design 95 or even issues with our piloting skills.

But even if nothing goes wrong and your aircraft flies well, log analysis can help you assess how well your aircraft is performing. Figure 6 shows plot examples of data logged by a Pixhawk flight controller. Of the many tools for log analysis, one of the most commonly used is Flight Review. Flight logs are also handy when asking for help in the official PX4 support channels.

But even if you know how to interpret the data graphs, it will take a while until you understand what values are acceptable in each case, and which plots are better to look at when dealing with specific problems, such as frame mechanical vibration. The PX4 site has good introductory information on how to analyze flight log plots and identify common problems. Figure 7 shows the quadrotor drone I used with the V5 Plus for my flight tests in the field.

It is pre-built and automatically installed by QGroundControl when appropriate hardware is connected. In order to access these ports, the user must remove the Pixhawk 4 casing. The pinout uses the standard Pixhawk debug connector pinout opens new window. For wiring information see:. The complete set of supported configurations can be seen in the Airframes Reference.

Note Connector pin assignments are left to right i. TIP Most users will not need to build this firmware!

|

Belt And Disc Sander Lidl 5th Minwax Tung Oil Finish Ingredients Technology Router Plate Insert Rockler 30 T V Unit Wood Work Designs |

SAMURAY

05.07.2021 at 12:37:41

BAKILI_QAQAS_KAYIFDA

05.07.2021 at 20:47:17

Leonardo_DiCaprio

05.07.2021 at 11:59:11

POLICE

05.07.2021 at 19:38:37

Rahul

05.07.2021 at 23:24:38