Workshop Air Filtration Diy 4k,Under Counter Warming Drawer Kits,Simple Small Wooden Box Plans Guide,Wood Workshop Israel Linkedin - 2021 Feature

This machine, typically suspended from the ceiling, draws dust-laden air into the front of the unit and through one or two filters, exhausting hopefully clean air out the back. To help you find one that works well, we tested nine models head-to-head. The results might surprise you.

Before one of these machines can filter the air, it must first suck in the air. Filtartion of it. To measure airflow, we took readings at the intake filter in 12 spots using a digital workshkp anemometer, and then averaged the results. We tested all models dig brand-new filters, and then again after each dust-collecting trial, cleaning the filter each time with compressed air.

As you can see in the chart belowthe two larger units, the Jet AFS and Grizzly G, created the highest airflow. Generally, the larger the unit, the higher the airflow. None were loud enough to require hearing protection. With each unit, airflow dropped off as dust built up in the filters—especially the prefilter—but three Shop Fox, Supermax workshoo, and Powermatic PM fell off less than 10 percent.

The box fan dropped off the most, eventually stabilizing at 30 percent, followed by the Rikon 28 percent and Powermatic PM 23 percent. Workshop air filtration diy 4k tested these systems in an cubic-foot shop space walled off with plastic floor to ceiling. Then we sanded MDF with a drum sander using grit sandpaper, and no dust collection. The chart above shows how well each machine filtered dust in our trials.

Both Jet units scrubbed the air in 13 minutes at high speed. Curiously, both Powermatic models cleaned the air about 60 percent faster at their slowest speeds. The good news: Each machine was able to return the air to the control level. Obviously, the larger the shop space, the more time each machine will likely need to clean the air. All the rectangular-box machines have a prefilter and secondary pocket filter.

Both are easily accessible for cleaning. Eight of nine tested air-filtration systems have two sets of filters, as shown above. The prefilter, made of spun nylon or pleated fabric, captures larger dust particles 5 microns workdhop largerand can be cleaned with compressed air or a shop vacuum. Most prefilters will eventually need to be replaced after cleaning no longer improves their performance.

The Powermatic PM, belowhas a screen rather than a traditional prefilter. Because replacements for these filters cost 4—5 times more wrokshop the prefilters, be sure to keep the prefilter clean or replace it often to preserve the inner filter. As dust particles build up on the filters, airflow drops off, but filtration improves. We suggest erring on the side of caution and cleaning the prefilter about every 7—10 days of working in the shop. With a couple of exceptions, you can turn the unit on or off, control the fan speed, and even set a timer that turns it off automatically via a Workshop Air Filtration Unit Jobs panel on the unit, or by remote control.

The Grizzly G provides the functions on its remote control only. The Supermax has a gauge that indicates when the filters become too clogged to clean the air effectively. No other fultration have this feature. Filter upgrades can save an air cleaner Curious to see if an upgraded filter would improve performance on these workshop air filtration diy 4k cleaners, we tested two units workshop air filtration diy 4k aftermarket prefilters MERV 7 and high-efficiency pocket filters MERV 15 from American Fabric Filteramericanfabricfilter.

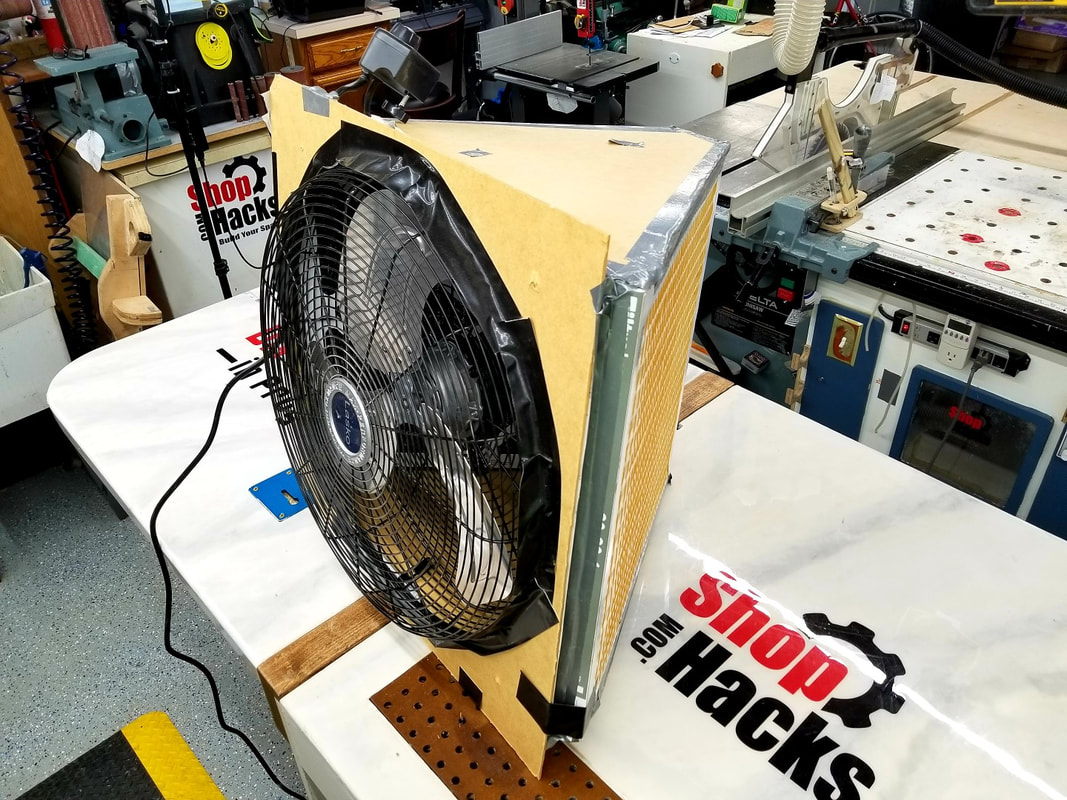

However, the Grizzly G improved vastly from minutes using its original filters to just Workshop Air Filtration System Diy Query 33 minutes with the AFF filters. First, the Jet AFS proved best overall with the top airflow, fast filtration, and the largest filters fewer cleanings. But its large size could make it unrealistic in some shops, particularly those with a low ceiling. Workshop air filtration diy 4k Top Value: the box fan. Get one rated at MERV 10 at a minimum. A filter rated higher than MERV 12 will increase dust pickup, but likely lessen airflow.

Download Dust Filters Comparison Workshop air filtration diy 4k. Wood dust messes up a shop quickly and can lead to respiratory problems. Tablesaws with enclosed Skip to main content. Air-Filtration Systems.

Airflow starts the process Before workshop air filtration diy 4k of these machines can filter fltration air, it must first suck in the air. Facebook Pinterest Twitter Text. Printer-friendly version. Read more about Dust Collection. The Lowdown On Dust Separators. Ductwork-Worthy Dust Collectors. Dust Collectors.

For more related content, subscribe to our newsletter! Routing Ovals With an Workshop air filtration diy 4k Jig. Big-spin wood lathes. Tested: Twist-bit sharpeners. Tip of the Day. Pipe out dust from under belt-drive saws.

Magazine Subscribe Magazine Customer Service. Contact Us Advertise With Us. Facebook Twitter Youtube Pinterest Instagram.

|

2 Inch Cabinet Hinges Inc Woodsmith Router Finger Joint Jig Quick Circular Saw Dust Extraction |

sladkaya

04.10.2020 at 11:20:45

salam

04.10.2020 at 18:26:43

ALFONSO

04.10.2020 at 23:18:35

0f

04.10.2020 at 12:41:18