Table Top Cnc Lathe Machine Gun,Xilinx Open Hardware Manager User,Best Sanding Belts For Woodworking Vessel - And More

Since the hardest thing about an OBB weapon is to get it to stop repeating, I am inclined, just this once, to agree with them. Seems to me that the minimum standard for a barrel is that one shot can be fired accurately, without hurting the shooter, and without destroying the rest of the gun.

Which is the harder problem? Obtaining steel rods suitable for barrels, or boring the barrel out, or rifling the bore? Boring, for a pistol-length barrel at least, is also not all that hard with a decent medium-small lathe. Rifle-length starts to require much more expensive machines and drill bits, naturally. Steel of all Grades and Sizes can be order from any area that still has some Machine Shops in Business, you just have to Pay for it.

It would be Cheaper and Faster in the Long Run. Who knows what the Future might bring? As others have pointed out, why not just make a manual rifling machine? We could do that, but rifling was a difficult process back then. Urban warfare is a noisy business. When it is suppressor-quieted, the quiet ones have huge advantages, perhaps enough advantage to overcome the Zombie use of sensor tech. Learning to CNC guns is, technically, something fun to do in your spare time.

Additionally, you get an unlicensed gun afterward! It is my understanding that one of the points of this is to demonstrate that making an entire gun from scratch is readably possible for someone who intends to do it. Barrel blanks are cheap. One rifle blank will make two or three pistol blanks. Even the chamber reamers are easy to replicate for someone who has a cnc lathe or novice lathe machining skills. Check out P. Not a beautiful end product, but functional. Gun control is indeed very dead.

You can make a simple blowback pistol cartridge carbine fairly easily. Just use a very heavy bolt. To make it a semi-auto, you would need to add a real firing pin to the bolt, instead of the usual SMG firing nipple on the bolt face.

Either spring load the firing pin, and use sear to prevent the pin from gong forward mauser style ignition , or put a hammer behind the bolt. If you are in the jurisdiction if the District Court of Illinois it is just as legal to make a fully automatic firearm for personal use as any other firearm.

See the Rock Island Arsenal case for more info. It can prosecute based on o , which is part of the Federal Criminal Code. All that occurred in Rock Island was that the federal prosecutors picked the wrong charge, and the courts called them on it. For improvisation of course the Phillipine Guerilla gun works just fine smoothbore. I thought that the teddy bear indistry was more regulated than the gun industry!

Bullets can be cast, cut or swaged from any appropriate metal alloy. Primers can be re-built using certain types of match heads. Rifling is almost trivial. One heavy plank for a stable spine, and a wooden cylinder with the twist cut in it is the basics of a pre or so rifling machine. Boring the barrel is a bit more complex but the Pennsylvania gunsmiths managed with wooden boring machines.

The real problem may be threading the barrel and action, since that is going to take a lathe or some really strong arm work. But the Afghans use homemade treadle lathes and files to build serviceable Lee Enfields. If you take your time and use plenty of lubricant, some of the old timers used cold stream water to cool the barrel and flush out chips, a couple of inches at yards is a reasonable expectation. Wrap your electrode with a spiral dielectric that can withstand the plating solution and is thicker than the depth of rifling you want, center the electrode in a smooth bore, hook up the leads, submerge in plating solution and apply power.

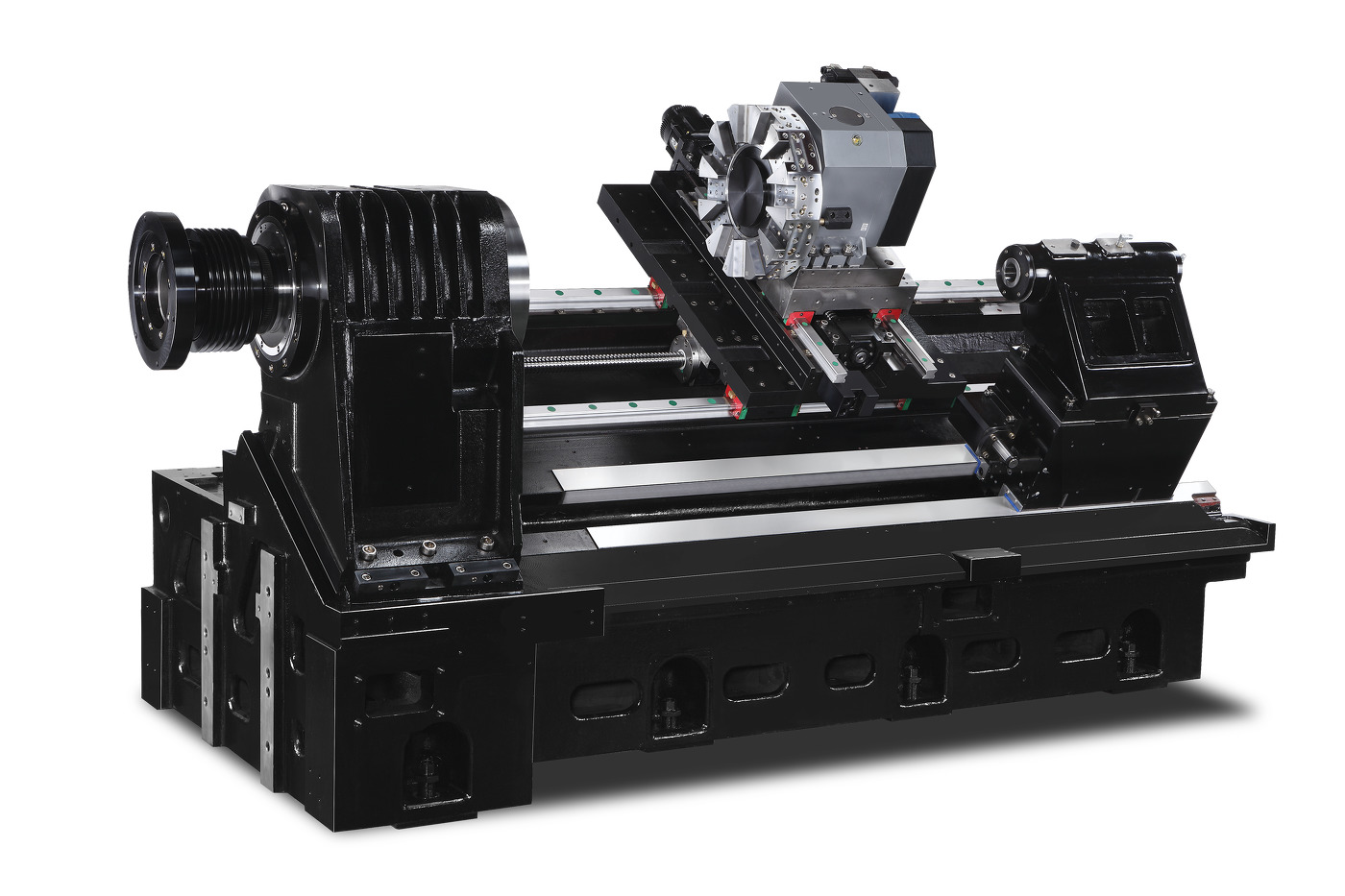

Garrett Lee says:. Mar 2, at am. Sigivald says:. Mar 2, at pm. Mar 3, at pm. Oliver Perry says:. A lathe machine consists of several parts that are attached to each other. A properly assembled lathe machine is very important since there is a lot of resistance that happens when a lathe machine is operating of heavy metals.

A lathe leg holds the machine in fixed position and they are also important for the purpose of flexibility when it comes to adjusting the working height.

This is one of the important parts of a lathe machine. A headstock comprises of three main things: spindle, speed change mechanism and gear shifts. A headstock is usually the strongest parts as it houses 3 main parts of a CNC machine and it has to bear a lot of vibrations and resistance due to the CNC machine operations.

A spindle is housed in the head box and is attached to the pipe that is then linked to the chuck. The chunk holds the workpiece and also makes it twirl around as per the requirements of the finished product. There is even a formula to decide the cutting speed of spindle, it is determined by. A gearbox is the part of CNC machine that is responsible for controlling the speed of the motors.

It is housed in the headstock and turns the chuck. The tailstock is located opposite of a spindle. It is a movable part of the CNC machine and can be changed as per the requirement of the finished product. The tailstock is made up of a barrel which can move either forward or backward. The barrel can also be used to support the material.

A carriage rotates in either right or left direction and is made up of saddle, composite support, traverse slide and top glide. It is an important tool which helps mount the tool post. A saddle is located over the carriage of a CNC lathe and it helps the cross slide to move backward of forward on a lathe machine. It is usually in H shape. The composite gives support to tool post and is a helpful component used when you are working materials that required sharp angles.

It is located over a cross slide and helps in swivelling. Similar to composite glide, traverse slide is located over the carriage and moves in backward and forward direction on saddle. You can use the traverse slide to engrave on hard metals using the hand wheel. The tool post is located over the composite rest and is used to clamp your engraving tool. A lead screw is a long shaped rod that has threads and is located on machine bed. This is a very helpful part of the CNC lathe machine which helps do automatic feed to the carriage from the stock head till its tail.

The apron is located in front of the saddle and has quite a few parts attached to it like hand wheel and lever systems which help you adjust the carriage rotation on the bed.

The bed is one of the most important parts of a lathe machine and is one of those parts which rarely moves. It is usually fixed in a position and supports other parts of the CNC machine such as headstock, tailstock, carriage and many others. Usually there are quite a fixed number of operations that are conducted using a lathe machine. Some of them are turning, cutting, sanding, grooving etc. Even before you conduct any operation on a CNC lathe machine.

You should be aware about terms like cutting speed, depth of the cut and feeds. Once you know the nature of the operation and are fully aware about the input details then only you should go ahead with any operations since any small mistake can prove to be fatal. This is one of the easiest lathe operations where the material of metal is sheared from the end so that it can fit in the right angle of the axis and get rid of any marks.

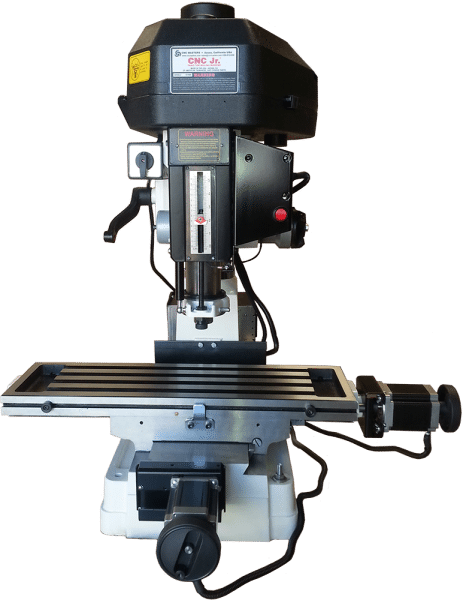

This is an operation where you simply narrow the shape of a metal to a cone shape using some compound slide. In order to change the angle of the operation , you can do so by adjusting compound slide. Whenever you have to cut a material parallel to the axis then you use this operation. This allows you to decrease the diameter of the metal. Some tools which help in conducting different lathe operations are:. In a vertical lathe machine, the workpiece rotates in an upright position pretty much like you would see when a potter moves the pottery wheel, it allows the spindle to cut at hard to reach angles and positions.

A CNC vertical lathe machine is used to operate on large and heavy materials, so huge that they are loaded with cranes.

Another advantage of a vertical lathe machine is that gravity always favours its operations which means throughout the operation of the machine, the workpiece is always stable.

This allows for better spindle movements and accurate cutting. On the price point, such machines are very expensive. The CNC horizontal lathe is the one that you mostly see in workshops.

These machines rotate a particular piece of metal in a cylindrical manner and while the entity rotates, CNC horizontal lathe machine operates on the material using tools to give it the desired form and shape.

Such machines also tend to have larger footprint than vertical CNC lathe machines. Even the chuck in horizontal CNC machines hold the object vertically. These types of machines are usually used for lighter materials.

Choosing the right CNC lathe machine can be a hectic task. There are quite a few factors you need to consider like the quality of clamps since they hold the workpiece steady.

|

Merillat Cabinet Drawer Slide Parts Maloof Oil Australia |

Bad_GIRL

14.01.2021 at 17:29:19

8

14.01.2021 at 19:11:44

qeroy

14.01.2021 at 16:38:38