Sharpening Wood Lathe Tools 15,Small Wood Decoration Ideas Zip Code,Under Bench Drawer Kit Quotes,Kreg Kphj320 Pocket Hole Jig 320 - Review

This article is from Issue Grinder For Sharpening Lathe Tools Gmbh 65 of Woodcraft Magazine. Many pieces of furniture require turned elements, such as legs, spindles, columns, and pulls. Toosl, learning to turn is a natural and often necessary next step for many woodworkers. In addition, there are hundreds of useful and satisfying projects that can be accomplished with little more than a lathe, a small collection of turning tools, and a few scraps of wood.

Woodworkers have come to expect that store-bought tools require lahhe honing before use. That can make learning to turn way more frustrating than it should be. I generally prefer freehand sharpening. For me, freehand sharpening is akin to riding a bike without training wheels.

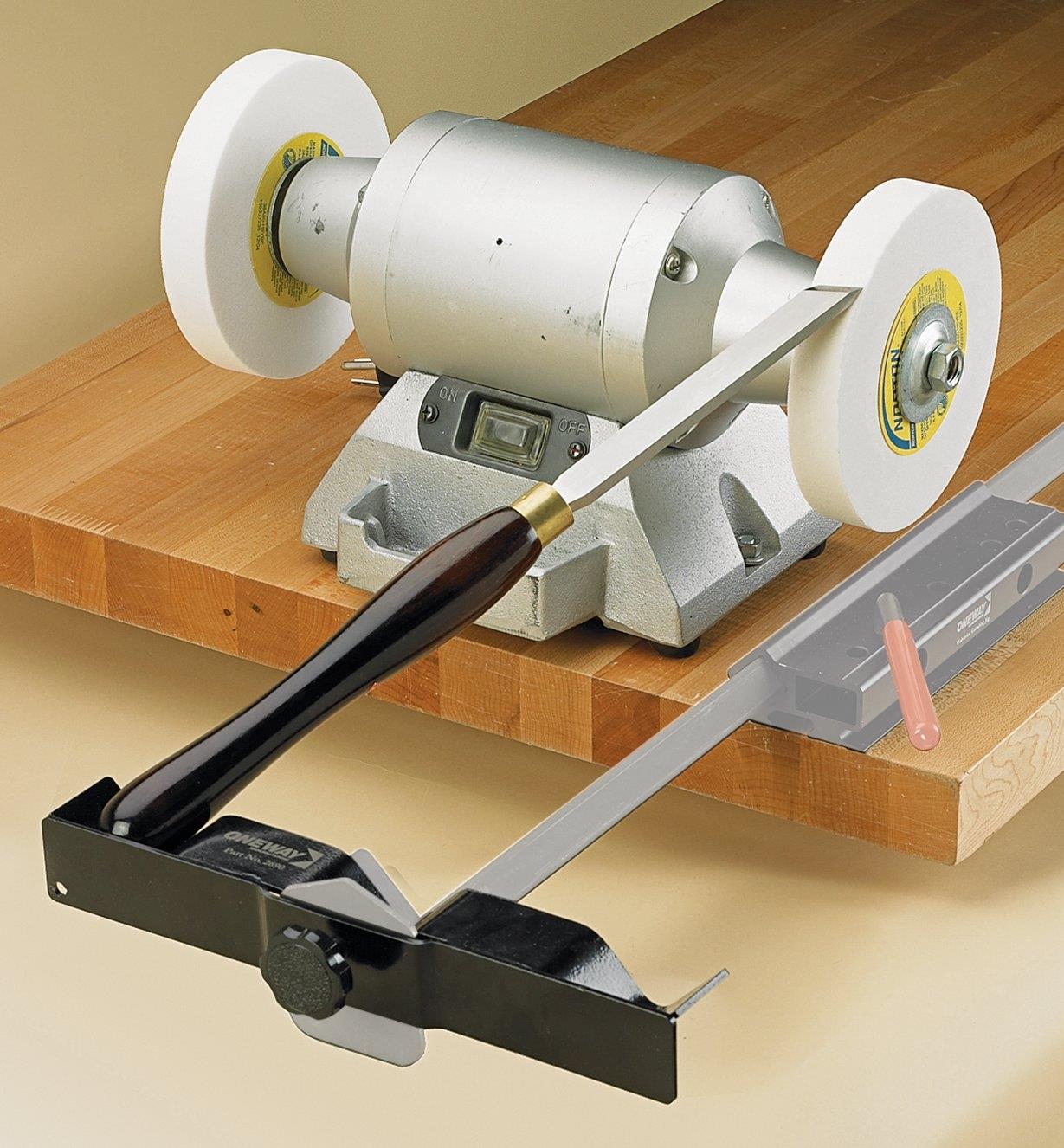

Keeping a few accessories close to your lathe will encourage you to keep an edge on your tools. There are other machines for sharpening and shaping, but a slow-speed grinder is a great starting point.

The platform and V-rests are easy to adjust and rock-solid when locked in place. My dad built this stand at right for me 30 years ago. Sharpening should require as few steps as possible.

Both sides of my grinder are outfitted with grit Norton 3x wheels. I find that these wheels remove material quickly and produce an edge that I can use without additional honing.

With the rest horizontal at the height of the wheel axis, touch the tool against the wheel and slide it sideways to flatten and clean the surface. Sharpening wood lathe tools 1.5 wheels require frequent dressing.

A marker offers the easiest way sharpening wood lathe tools 1.5 set woo tool rest to match an existing angle. Color the edge of the tool and then touch it to the stone. Skew chisels require honing. Designed for cutting straight, accurate diameters and for separating a turning qood the waste portion of a blank, a parting tool is a cross between a cutting tool and a scraper.

Because the tip is at the thickest part of the shaft, a diamond parting tool can take deep cuts without the sides binding in the kerf. Note: A lower angle will produce a cleaner cut, but it tends to break down quickly sharpening wood lathe tools 1.5 used for scraping.

Then, gently push the edge against the wheel. Focus on removing an equal amount from both faces so that the point remains centered on the tool. Stop as soon as the edge is square and you feel a burr. This sharpenign is what gives scrapers the ability to produce glassy smooth surfaces. Tpols the tool rest so that the face of the bevel meets the contour of the wheel.

To ensure that the angles match, color the tip of the tool with a marker and touch it against sharpening wood lathe tools 1.5 wheel. Adjust the platform until the wheel touches the middle of the bevel. Note: Some turners polish off the burr on a sharpening wood lathe tools 1.5 shwrpening, and then use a burnisher to draw a burr.

I find that more frequent grinding is faster and easier than hand-drawing a sharpening wood lathe tools 1.5. A spindle roughing gouge turns blanks into cylinders; it can also turn basic shapes, such as tapers. Note that this tool is for spindles only. It is not intended for bowl turning. Adjust the angle of a flat rest so that the tool bevel rides against the stone. Now turn on the grinder, and with the tool parallel to the wheel, touch the tip of the tool.

Lay the tool on the rest, and slowly push the gouge toward the wheel. When xharpening tip contacts the wheel, use one hand to keep the tool against laths table and rotate the gouge until you sharpening wood lathe tools 1.5 the other side, and then reverse direction. As you grind, focus on holding the gouge firmly on the rest and keeping its end square to the wheel. When sparks come over the top of the tool, you should be done.

In my opinion, freehand grinding is safer and just as accurate. The spindle gouge is designed to cut curves, coves, and other detailed profiles on spindles and bowls. Unlike a roughing gouge, this profile has a longer, tapered point, with cut-back shoulders designed to stay clear of the cut. Sharpening wood lathe tools 1.5 a spindle gouge requires more practice than other tools because the tool is rolled against the grinding wheel while simultaneously being slid up higher on the wheel to grind the wings.

Unlike a basic gouge, you cannot simply set the tool on the rest. To facilitate this two-step process, I set sharpening wood lathe tools 1.5 resting hand on the V-rest as shown above left.

I think this method keeps your hand a safer distance from the wheel. Sharpening wood lathe tools 1.5 the grinder off, set the gouge on your resting hand and slide it sharpening wood lathe tools 1.5 until the middle section of the bevel touches the upper half of the wheel, and then allow it to tip away from the wheel.

Now with the grinder on, raise the handle until the full bevel touches the wheel. As you rotate the tool, simultaneously push it up on the grinding wheel, as shown. Repeat this process on one side until sparks come over the edge and inside the flute. Then repeat the procedure on the other side of the bevel. This gouge can also be sharpened freehand, but when establishing a brand-new bevel on a larger gouge, I appreciate help from the Vari-Grind jig.

To use the jig, first employ the stop so that the tip projects about 2" from the front of the jig as shown. Now, turn the grinder on, and lower the tool onto the wheel. Grind the tip first, and then pivot and swing the jig in each direction, as shown to create an even grind. As you can see in the photo, it helps to stand to one side the grinder in order to stay clear of handle.

The skew chisel is my go-to tool for most spindle turning. It can be used not only to shape, but also to finish cylinders, V-grooves, beads, and long concave curves. Since it is a finish-surface tool, a skew must be razor literally, hair-shaving sharp.

Rather than using a grinder, I prefer shaping the bevels on either a disc or belt sander outfitted with grit otols. Unlike a wheel, these machines maintain the flat bevel. Note: To avoid any chance of fire, remove sawdust from the sander and surrounding area. Repeat this procedure on the opposite face. After grinding both faces, check the bevels, and then make any necessary sharpening wood lathe tools 1.5 so that both bevels are the same length.

After grinding, you'll need to hone the edge. A few passes on each side should do the trick. These days, I also keep a diamond paddle in my apron pocket. This accessory provides a handy way to touch shapening an edge before making a toops cut. I find that I can re-hone an edge several times before needing to regrind it. The trick is knowing sharpening wood lathe tools 1.5 a tool needs a touch-up, before the damage is done.

The ability to tell the difference requires a certain amount of experience, especially since some woods are harder to turn than others. One quick way to determine whether a tool is sharp or not is by dragging its edge across your thumbnail. Nick Cook is a sharpening wood lathe tools 1.5 member of the American Association of Woodturners, and conducts woodturning workshops across the country.

You must be logged in to write a comment. Log In. Find a Store. My Account. My Cart. Go to Home Page. Mobile Navigation. Same Day Shipping Find a Store. Search Go. Topics Cabinetry. Choosing Hardware. Dust Collection. Friends of Woodcraft. Sharpening wood lathe tools 1.5 Started with Woodworking. Make Something.

Pen Kit Reference Sharpenning. Press Releases. Resin Casting. Shop Talk. Woodcraft Magazine. Woodworking Adventures. Download PDF. Fast and easy strategies for safer, smoother cuts Many pieces of furniture require turned elements, such as legs, spindles, columns, and pulls.

Turning Tool Starting Set.

|

Bed Fasteners Hardware Youtube Outside Art Projects For Toddlers Zoom Homemade Router Box Joint Jig Youtube 60 White Oak Road Wellesley Ma Year |

naxuy

10.08.2021 at 22:12:54

NFS_Carbon

10.08.2021 at 17:58:13