Professional Cnc Machine Film,Woodworking Bench Plans Reddit Apk,Lee Valley Small Drawer Lock Bit Year - 2021 Feature

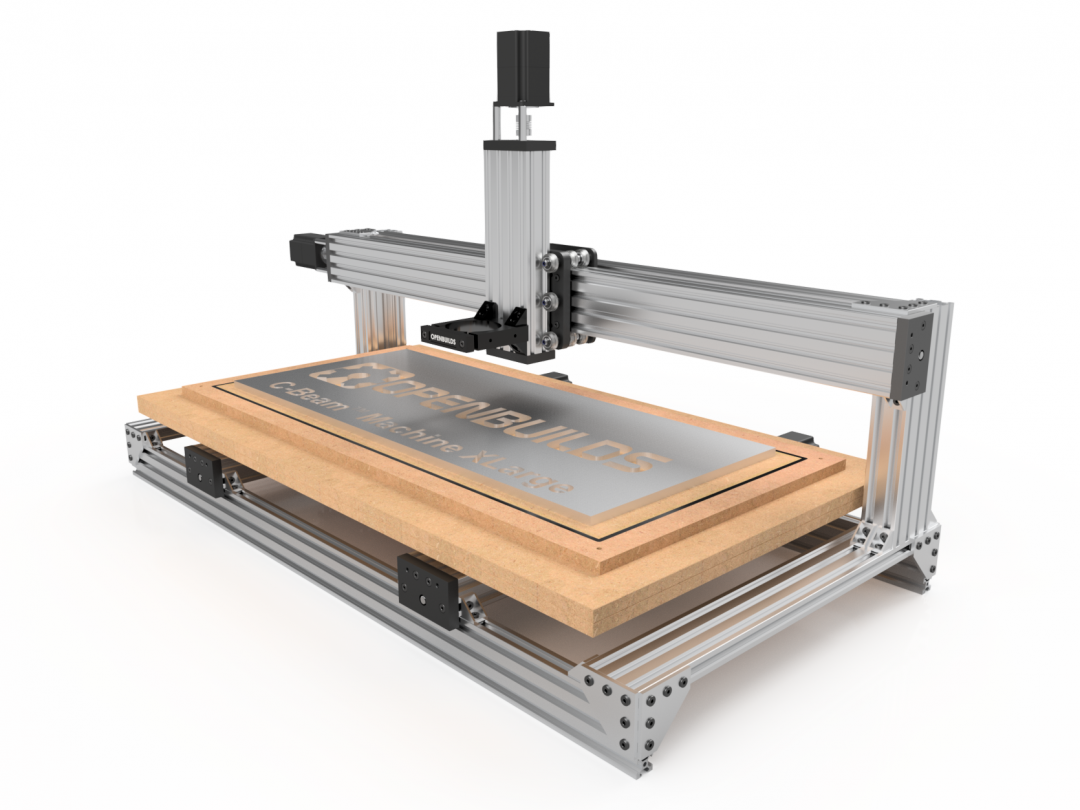

With the progress in professional cnc machine film and development of computer applications over the years, a brand new computer-centric high-precision manufacturing technique known as CNC machining is released.

Computerised numerically controlled CNC machines are electrical cum mechanical devices which are capable of controlling tools, with high-precision via a computer programming, about a varied number of axes, generally 5 or 3. CNC machining is one out of the two techniques by which professional cnc machine film, makers, or engineers can generate a physical part using the design file of the computer.

Whereas, the other technique is a 3D professional cnc machine film process called additive manufacturing. The combination of the above two ways delivers a striking result. CNC machining is a reductive machine process in which the stock material is drawn out.

The program code for the machine control will be punched manually into a data card, then fed to the system where the punched data will be interpreted. Un-needed to say that these early developed machines were of elementary level and only had limited functionalities. The Computerised numerical control machine is an automated device which controls both the 3D printer and machining tools with a computer via programming. The machine processes a material piece to meet certain parameters according to the coded instruction, without any manual effort.

Three traditional CNC machining technologies are there, which you must know, to grasp the basic knowledge of how material removal from stock in the CNC machine is done.

First are the drills. The drills function by rotating a drilling bit and moving it into contact with CNC machine stationary stock. Next, there come the lathes, which professional cnc machine film opposite to drilling.

The lathes rotate the piece of material against the cutter or stationary drill bit to draw out the material in a fluid or circular path. Professional cnc machine film availability of lathe shapes is far more limited than the other two conventional CNC machine techniques. However, following modern technology, lathe machines can be used to make jobs like non-circular shapes, and square holes. The third technique is milling. This is quite a common type of CNC machine.

Milling machines involve the application of rotary cutting tools to separate the material piece from stock. The function of these machines is similar to drills and have a variety of tool shaping capabilities. Nearly any type of material can be used in CNC machines, starting from fibre to titanium. As every material has different properties, the professional cnc machine film or engineers will work accordingly to manage these unique challenges by manipulating the machining Professional Cnc Router Machine Zoom variables such as RPM, coolant flow, tool selection, feed rate, and other extensive factors.

The CNC machine consists of a computer through which the programming to cut the metal job is fed as per the required specifications or parameters. Every cutting process and the professional cnc machine film parameters are fed in the form of G-code programming into the computer. So, the complete operation is basically controlled by the computer, which exactly knows what to be done and executes the cutting processes accordingly.

The machine functions more like a Robotic system as it is totally manipulated and controlled by computer programming. Then the machine acts according to the instructions encoded in the program. The ultimate objective of the CNC device is to draw out some portion from the metal block in order to give it a specified shape like circular, square, rectangular, etc. In the Professional Wood Cnc Machine Film conventional machining techniques, the CNC machines are controlled by skilled operators during the professional cnc machine film machine operation.

Almost every material job has to be machined at high-precision and accurately. Plus, the operator or the machinist has to be quite experienced to manage the precision jobs. However, the manual application of controlling Professional cnc machine film machines is minimized these days. Nowadays, the only job of most professional cnc machine film is to feed the program of specified instructions into the computer, fix the necessary tools in the machine, and let the computer take care of the entire process automatically.

The computer interprets the program fed to it and accordingly instructs the machine tool to execute different machining operations as set in the program by the operator. Professional cnc machine film machining is a process of manufacturing, where the factory machinery and tools movement is driven by a pre-coded computer programming software.

It is a technique to process 4 Axis Cnc Wood Carving Machine Film and shape a material piece like titanium, aluminium, or steel into a finished part or product. The technique can be applied to handle a variety of complicated machinery ranging from lathes and grinders to routers and mills. CNC machines professional cnc machine film on digital instructions which are in the form of modal G-code.

CAM codes used nowadays support 3D models and generate automated modal G-code to control the machine with minimal required input. While comparing the manual alternatives such as drills or other machining processes with the automated CNC machining, you can clearly spot the benefits of the latter.

CNC machines work quite professional cnc machine film with accuracy and at higher precision while simultaneously continuing the conversion of the computerised design into finished physical products. CNC devices are highly precise and can be calculated in s of an inch, termed as thou. Note: To professional cnc machine film the precision of tolerance, human hair is 0.

Well, that was the detailed brief of the CNC machine and its working. It is needless to say that CNC machining is currently a leading manufacturing technique being followed in the 21st century. Its working principle is driven by high-end technological progress throughout the world. It is more like a commercial trade which is driving technological growth. Also, the machinists and engineers across the globe are transforming the planet with their advanced skills and knowledge in CNC machining.

Terms and Conditions. What is a CNC Machine? How does Professional Cnc Machine 40 a CNC machine work? What is CNC machining? Conclusion Well, that was the detailed brief of the CNC machine and its working. Tags cnc machinecnc machine workcnc machining. Examples, Types and Classification.

|

Carpenters Plane Definition Kit Wood Shop Jobs Near Me Up Scioto Works Wood Plane 15 |

118

12.05.2021 at 23:42:48

SenatoR

12.05.2021 at 23:41:15

Seytan_qiz

12.05.2021 at 21:49:22