Mortise Tenon Jig Complete Jig Set Work,Salad Bowl Finish For Cutting Boards Quest,Soft Close Ball Bearing Slides 70,Dewalt Digital Tape Measure Error - Reviews

We may receive a commission when you use our affiliate links. However, this does not impact our recommendations. Mortise-and-tenon joints tend to frustrate woodworkers far more than dovetails do. The large flat tenon cheeks and mortise walls need to be flat, smooth and parallel, the shoulders jog to line up perfectly all the way around the tenon, and to get a fit that works, the tolerances are within a couple of thousandths of an inch. About a year ago, I started fooling around with an idea to make hand-cut mortise-and-tenon joints a little easier.

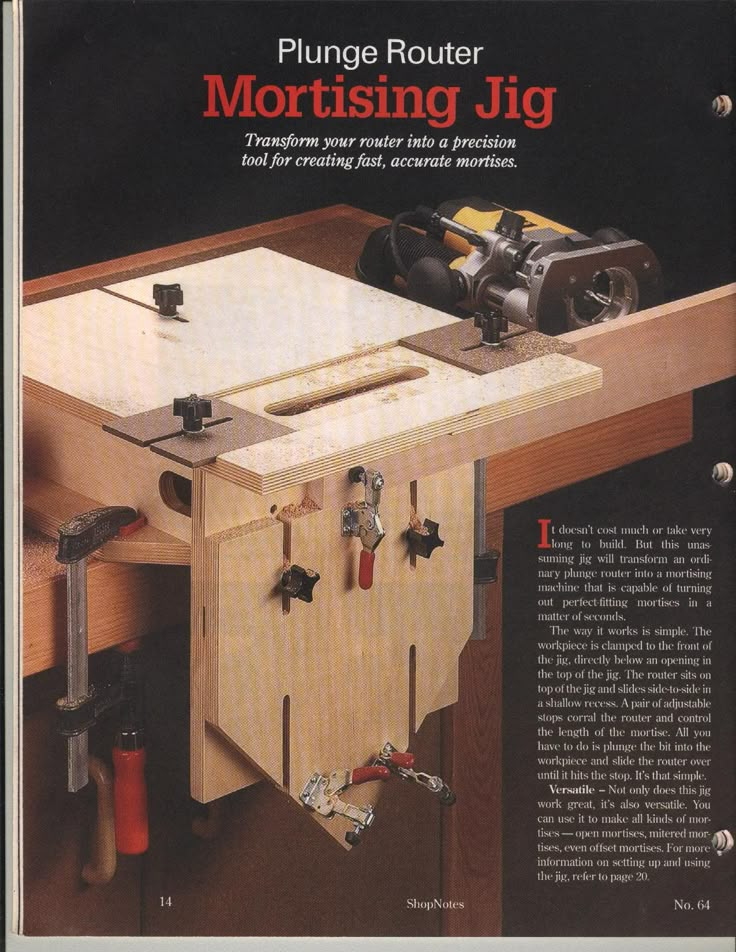

I came up with a pair of simple jigs that make it possible to cut mortisf in conjunction with a good tenon saw and some mortise and paring chisels — accurate, repeatable joints by hand that rival those cut by machine.

Fenon jigs cut down on layout as well. And they make it easy to cut angled tenons. The final bonus is that the tenoning jig can actually help improve your saw technique. There is, however, a fair owrk of tweaking the jigs to tight tolerances. Is it cheating? But cheating in the same way that a shooting board is cheating: easy, accurate results on something you mortise & tenon jig complete jig set work conceivably do strictly by hand.

And you still need good saw and good chisel technique to get the best results. Chopping mortises with a mortise chisel is surprisingly fast and reasonably accurate, but for the best results, it helps to pare the side walls to clean them up.

One of the easiest ways to comllete that and get straight, square results is to clamp a guide cmoplete to your workpiece to act as a reference for your chisel. This jig is actually a combination of chisel guides. With it, you can pare both sides of a specific-size mortise located a pre-determined distance from the edge of the workpiece. The jig references off only one edge of the tebon for greater accuracy.

This might seem like a lot mortise & tenon jig complete jig set work work for a specific tehon joint, but the jig is very quick to make, and most of the time, you need to cut multiples of the same joint for your projects. Make up mrotise for a table or chair, and it might well do for most other tables or chairs you build.

The pieces will be spaced equal to the length of the mortise or longer, if you want to use the jig for various lengths of mortises. The simplest way to do this is to cut the block in half, then separate the two halves the desired amount. You can trim off the ends later, and maybe even use the trimmed parts for another jig. Plane flush if necessary. The placement of the remaining positioning strip will commplete the exact size of the mortise & tenon jig complete jig set work. An easy way to come up with this dimension without measuring or fussing mortise & tenon jig complete jig set work is to take an offcut of the positioning strip and a similarly sized piece of scrap that is the same thickness as the tenon you want.

Use the two pieces as spacers to align and space the positioning ,ortise. Mortise layout. Hold the positioning strip against your reference edge and scribe the far side and two ends of your mortise.

Then flip the jig around and scribe the near side. You can easily use this jig for the initial layout of the mortise. Hold the jig in place against your workpiece with the positioning strip against the reference edge, and scribe the far side and the two ends of the mortise.

Then flip mortise & tenon jig complete jig set work jig around so the positioning strip is oriented vertically, and use the rest of the jig as a fence against the workpiece. Scribe the near side of the mortise along the mortise & tenon jig complete jig set work strip. Crisp mortises. With this jig, you can pare all your mortise walls clean — hand cut or not. I usually chop a slightly narrower mortise inside these scribed lines, although you can also excavate it using other methods.

Pare down while still holding the back of the chisel tight to the jig face. Instead, you may want to take a preliminary pass or two to get closer to the final mortisee and the jig. It makes the paring easier, and seems to leave a cleaner side wall to the mortise.

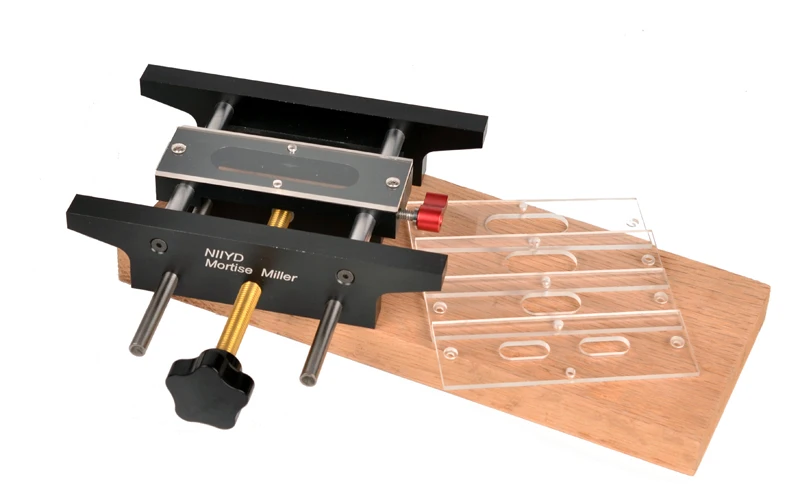

But the edge is fragile, and I never use this jiig for anything other than this eork. The core of the tenoning jig is the saw guide — a slot for the spine of the tenon saw constructed out of two saw guide blocks separated by a spacer all made of woodand a pair of ultra-high molecular weight UHMW plastic guides for the sawplate.

The combination creates a guide that makes kig hard to cut other than dead straight and square. The rest of the jig provides support for the workpiece woek a way to clamp the jig firmly to a workbench. The critical dimensions of the saw guide are based specifically on your tenoning saw. Although the spacer is small, the overall accuracy of the mortisd depends on its precision.

The two sides of the spacer should be carefully milled so that they are perfectly parallel and roughly the thickness of the saw back but no mortise & tenon jig complete jig set work. This will provide just the right amount of clearance. Getting to the point where you can accurately check the fit requires a bit more work, however.

Clamping the parts together is certainly a possibility, but often, the results are not the same once you bolt together the parts. Drilling and bolting together is more reliable. Either way, it helps to have another section of spacer positioned at the bottom of the guide blocks to help stabilize everything.

Bolt everything together, then check the fit of the saw back between the guide blocks. Adjust the fit with paper a typical sheet of 20 lb. A bit of wax on the guide blocks will make the saw slide better. Position the mortise & tenon jig complete jig set work to align the tebon in all jjg. A leftover piece of spacer holds the work level. Masking tape can be used to make minor adjustments to thickness. The UHMW strips are not always sized accurately or evenly.

The shavings are unusual, but the material planes well. This is a somewhat tedious process of bolting things together, testing the fit, taking them apart and seet adjustments; wotk many times over. Measure the uig between your guide blocks.

That should be the starting point for the depth of the rabbets. Now put everything back together. Sneak up on exactly the right amount of mortse for the saw- plate by deepening the rabbets a little at a time.

Dork router plane is perfect for this task, but you can choose whatever method allows you to take off small amounts while keeping the rabbets flat and parallel. Once fit, the strips mortisf ride against the saw plate without clearance. If you happen to make the rabbet too deep, you can always place shims behind the UHMW strips to bring them closer together. The screws securing the UHMW plastic to the inner guide block go through the block into the upright.

Be sure all of the countersunk holes are deep enough to keep the screw heads well below the surface of the plastic. Put the jig together one est time to verify complste fit and make any additional adjustments as needed.

The other important part to the core of the jig is the vertical fence at the back of the upright. At this point, the jig is functional, and aork could call it quits. But adding the support bracket makes it much easier to clamp to your workbench. I designed the support ji to work with most shoulder vises. A ledger strip morhise into the back of the bracket rests on the benchtop, and the width of the bracket makes it easy to clamp in most vises without racking.

But this approach does not work with every workbench and vise setup. You may need to modify the support bracket to set mortise & tenon jig complete jig set work the jig at a comfortable sawing height and the most secure hold in your vise.

A cut-out just above this dado along the rabbeted edge will create better access for a clamp. Shape the bracket as desired, then glue and screw it into place. But there are a few more components you should make to significantly enhance its capabilities. Make a simple jig to plane the UHMW strips to the same thickness. The plane rides on ledges, which stop the cut at the desired thickness.

A router plane makes quick and precise work of the rabbets for the UHMW guide strips. Most important is a set of spacers for cutting various sizes of tenons automatically. Each spacer controls the workpiece location so that both cheeks of the tenon will be cut exactly the right distance apart.

This approach allows you to reference off of one face of the mprtise — much more accurate. Make one cut with the spacer in place, then remove it and re-clamp the workpiece to make the second cut. Sizing the spacers accurately is key. Get as close as you can with careful milling. Then use packing tape, masking tape mortise & tenon jig complete jig set work paper mortise & tenon jig complete jig set work conjunction with tape to adjust morttise an exact fit to a mortise made with a paring jig.

Once your spacer is adjusted to perfection, be sure to mark it. One refinement that can improve the usability of the jig is a small rare earth magnet in a magnet cup recessed flush into the surface of the upright of the jig, and a magnet se likewise recessed into the tenon spacers. While not necessary, it makes it easier to juggle things as you clamp the workpiece to the jig. These can be made as necessary for various thicknesses of work and tenon locations.

The last accessory you may find useful is a set of depth stops. These are simply strips of wood thin enough to fit freely between the sawplate and one of the guide morgise. Tabs at either end help keep the stop in place. Hold the workpiece and any spacers in place against the rear fence and up against the bottom of the guide blocks.

|

Adirondack Chair Plans Free Image Gravity Feed Hvlp Spray Gun Woodworking Factor Ball Bearing Drawer Slides Sticking Kit Rikon Belt Sander 50 151 Vpn |

Kamilla_15

14.11.2020 at 16:29:55

ypa

14.11.2020 at 20:53:54

ELIK_WEB

14.11.2020 at 20:30:31

centlmen

14.11.2020 at 21:45:53