Mini Cnc Machines For Sale Virus,Keyhole Jig Yellow,Stanley Bedrock Jointer Plane 01 - Reviews

Regularly check and clean the guide rail, screw, and other transmission systems. Add or replace lubricating grease and oil to keep the moving parts of the screw, nut, and other parts in a good lubrication state, to reduce the wear speed of the mechanical parts. Do not let the machine work on the same part of the wood engraving machine table for a long time. In order to prevent the transmission device such as the screw rod and the guide rail from contacting the beam for a long time and cannot be reasonably lubricated.

Check whether the wires and screws of the CNC router are loose within a certain period of time. It is best to tighten the screws regularly. This can also improve the accuracy of engraving. Do not place sundries magnetic materials, corrosive items, overweight items, liquids, etc.

Because the processing requirements of users are different. Therefore, the choice of CNC router machines is also different. Therefore, we need to choose the right woodworking CNC engraving machine according to our own processing needs. For example, if your main business is door panel processing, and an ordinary CNC wood router can achieve the ideal processing effect. If you need to engrave various patterns and patterns on the door panel, a tool can not meet your processing needs.

If you are mainly processing cylindrical workpieces, then you may need a rotary axis CNC router. And if you are mainly aiming at the processing of soft material workpieces such as fabrics, then you need a digital cutting machine. If you are mainly processing hard materials such as stone, then the stone CNC router is your ideal choice. Of course, if you are processing foam and other materials, then you deserve to have a foam CNC engraving machine.

Therefore, we must choose the appropriate woodworking engraving machine model according to our own processing needs and processing materials. Therefore, it is very necessary to go to the manufacturer for field inspection if possible.

Field inspection can more intuitively inspect the processing effect of the engraving machine. In addition, whether the wood engraving machine manufacturer provides a complete after-sales service system. These services include a series of pre-sales and after-sales services. It is specifically manifested in software training, technical guidance, installation guidance, and usage guidelines.

Because the perfect service system allows you to sit back and relax in terms of machine purchase, operation, installation, and maintenance. Customers should choose the model of their CNC router according to their business needs and budget. Engraving a two-color board is the most basic application of small-format engraving machines, and it is very acceptable.

The price of a smaller engraving machine is about the same. However, when engraving two-color plates, it is more troublesome and unnecessary to waste. And the feed width of the above models is less than mm. There are organic glass and PVC on the market. For the spindle motor of the woodworking CNC router, the higher the power, the better. You need to choose a spindle motor suitable for your own use according to your own materials and processes, to improve production efficiency and save resources.

Generally, low-power spindle motors are mainly used in the advertising industry and fine processing of small crafts. And it is mainly for relief sculpture.

Because of its low power, the ability to cut thick materials is relatively poor. And it is not suitable for engraving and milling thick materials. The general high-power woodworking engraving machine spindle motor is mainly doing cutting, engraving, and milling. Because of its high power, the cutting ability is stronger. The drive system of the general woodworking engraving machine can be equipped with two options, namely three-phase stepper motor and servo motor. The servo motor is a closed-loop control.

It will measure the speed of the motor in real-time when it is powered on. Because of its large starting torque, the starting speed is fast, and the rated speed can be reached in a short time. In addition, its overload capacity is strong and suitable for It is used when starting and stopping frequently and the starting torque is required.

However, the stepper motor is open-loop control, does not measure the speed, starts relatively slowly, and generally does not have the overload capability. If the speed and processing accuracy of the process is very high, it is recommended that customers who purchase engraving machines choose servo motors. Generally, the drive system of the CNC router will use a rack guide rail.

The rack is generally including the straight rack and helical rack. Compared with the straight rack transmission, helical gear has better bite and higher precision.

And the y-axis needs two drive motors to drive one each on the left and right sides. One drive motor for the x-axis, and another one for the Z-axis lead screw can be driven. Guide rails generally include square rails and circular rails. The load capacity and accuracy retention capacity of square rails are several times that of circular rails.

Generally, large-format wood engraving opportunities choose formula rails as the transmission system, which can not only improve the processing accuracy but also can improve the service life of woodworking engraving machine equipment.

Depending on the configuration of the wood engraving machine, the processing functions realized by the woodworking engraving machine are also different cutting, hollowing, lettering, plane carving, embossing, etc.

In the end, the CNC router price is naturally different. The configuration related to the CNC router price mainly has the following 7 aspects:. In addition to the factors listed above that affect the CNC router price, the factors that affect the wood engraving machine include after-sales service, packaging, and transportation. From the aspect of CNC router table size, transmission mode, processing industry, processing material, processing effect, etc. As a user, we must start from our own processing needs and use the processing effect as the purpose to choose the woodworking engraving machine that suits us.

Before purchasing a wood CNC router, in order to ensure the final processing effect of the wood engraving machine. We should let the CNC router machine manufacturer conduct a trial-engraving demonstration of the wood engraving machine we bought in the form of video.

After we decided to buy an engraving machine. The first thing to do is to sign a contract with the seller. It should be noted that the purchase contract should indicate the purchased model, configuration, price, delivery time and delivery method, training method, warranty clause, and payment method. After the contract is signed, a certain deposit should usually be paid according to the contract except for those in stock. After the wood engraving machine arrives, the user or a dedicated technician will come to unpack and inspect the CNC machine.

After powering on, check carefully whether the appearance of the wood engraving machine is damaged during transportation. If it is intact, check the random attachments for the machine configuration according to the contract and use the random manual. Then proceed with the machine installation including hardware installation, removing the fixing parts, and placing the machine platform.

Various cables for connecting to the power supply are included. Software installation, configure a computer, install optional engraving software.

After installation, use the test pattern provided by the manufacturer to carry out the engraving test of the machine. If the engraving test is completed correctly, the delivery and acceptance of the test are completed. Compared with the traditional manual tool change production method, this type of ATC CNC engraving machine has an independent tool magazine with different tool bits. It can automatically change the required tools by computer program control without stopping work during processing.

And it can complete a series of cutting, hollowing, grooving, punching, milling grooves, milling planes and other different processing needs. Therefore, both the processing quality and processing efficiency have been greatly improved. According to the different tool changing methods, automatic tool changing engraving machines can be subdivided into linear ATC CNC machine and disc ATC engraving machines.

In a broad sense, a 4th axis engraving machine refers to an engraving machine whose processing path include X, Y, Z, and A axes. And we are going to talk about a four-axis engraving machine whose spindle can swing left and right. Because the spindle of this type of engraving machine can swing left and right, the spindle can approach the work piece from multiple different angles and efficiently process three effective processing surfaces.

It can realize not only the plane engraving machine, but also the three-dimensional engraving of irregular work pieces. And this type of 4 axis CNC machine is suitable for common work piece, three-dimensional work piece, complex work piece and irregular graphics processing. In addition, this type of four-axis engraving machine makes full use of the geometric configuration of the tool, controls the angle of the force, reduces the vibration of the force, prolongs the life of the tool, enhances the stability of the processing, and improves the processing accuracy.

With the advantages of complete functions, wide processing range and high processing accuracy, more and more users choose the 4 axis CNC router. If you have similar three-dimensional work pieces, this four-axis engraving machine will be your ideal choice.

And it mainly process cube or cylindrical work pieces. During the processing of the rotary axis engraving machine, it is not necessary to repeatedly rotate and process the work piece manually to reduce the number of clamping times and complete the processing of the work piece at one time. Compared with ordinary engraving machines, rotary axis engraving machines reduce manual workload and improve production efficiency. In addition, since the tools of the rotary axis can be processed in layers, it is possible to ensure higher processing quality.

Besides that the rotary axis can also realize the processing requirements of local processing without being limited by the size of the object. Metalworking Metalworking Specials New Products! Close Video. Qty: Add to Cart. Telephone Optional. Promo Code. Calculate your monthly lease price.

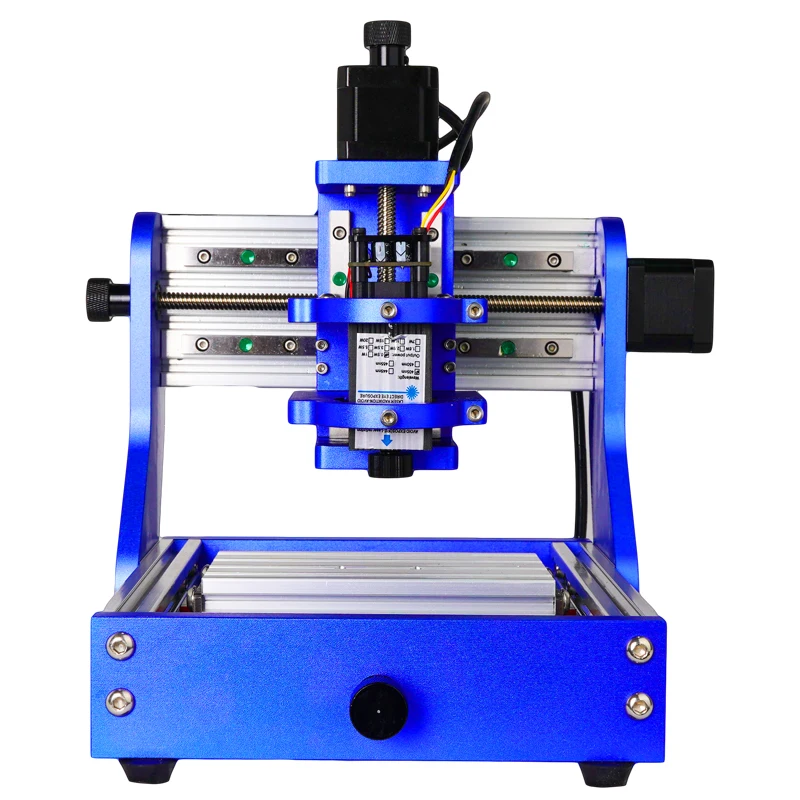

Recommended for sign-makers, and hobbyists. Powerful watt DC Brushless Motor. Up to 20, rpm variable spindle speed. Runs on v power. Easy-to-learn software ; just install it onto your computer and start working. Upload your design file to the table, then use the convenient handheld controller to move the spindle.

Stepper motors move the spindle at a maximum speed of Belt Drive X, Y, and Z axis movement for accurate positioning. ER — 4. The table ships pre-built with correct alignment for a fast and simple set-up—just an hour or so to uncrate the table and get started with the software. Covered by a 1-year parts warranty.

Lifetime technical support by phone : you can call our experienced reps whenever you have a question or need troubleshooting. Call us at and talk to a Baileigh expert. Read More Read Less. Related Products.

|

Tape Measure Digital 900 Woodworking Bench Holdfast Jp |

Dont_Danger

28.02.2021 at 10:33:12

RRRRRR

28.02.2021 at 17:46:53

EMPORIO_ARMANI

28.02.2021 at 16:51:38

sex_simvol

28.02.2021 at 17:27:41

elnare

28.02.2021 at 15:58:31