Making A Router Box Joint Jig Ups,Best Woodworking Roller Stand 70,Marking Knife Safety 2019 - Easy Way

Box joints are a strong, sturdy, and attractive alternative to dovetail joints. While a through dovetail joint is stronger than a box joint, it's also more complicated to create. However, as you'll see in the maknig steps, a perfectly-fitting, clean box joint is easy to quickly create with a simple box joint jig for your table saw.

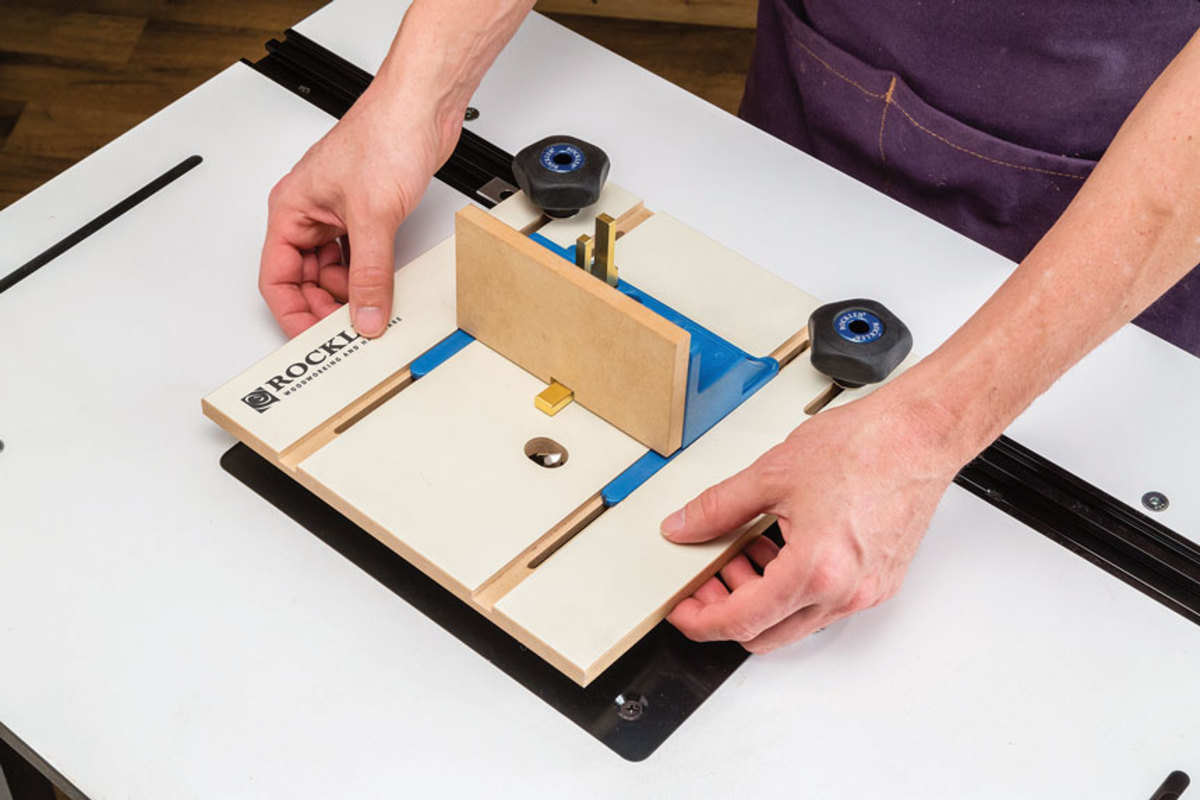

To begin making your box joint jig, determine what width you'll want each of the fingers of the joint to be. Once you've cut the two wooden pieces for the jig, install the stacked dado blade set boc your table saw. Position enough chippers in between the two outer blades so that the final width of the cut will match the desired width of the box joint fingers you determined. Attach the board to your table saw's miter gauge, as shown in the picture above.

Slip the miter gauge into the miter slot to the left of the saw blade and check to see that the miter gauge is set to 90 degrees perpendicular to the saw blade. Making a router box joint jig ups your drill to drive a pair of wood screws through the slots or holes in the miter gauge and into the block of wood.

Be certain that the screws are short enough that the point doesn't rouher through the face of noint board. With the board attached to your table saw's miter gauge, the next step will be to cut a notch on the board to accommodate a spacer block.

Slide the gox back toward your body, clearing the blade again, and then turn off the saw. After the first notch has been cut in the backer board, insert the koint block through the notch. Slide the spacer block so that the end is 2 inches past the front face of the backer board, and make a pencil mark on the spacer block against the backside of the backer board.

Cut the spacer block at this cut line. Retain both halves of the piece that you cut, as you'll need both pieces. Next, remove the miter rouher from the table saw and turn it upside-down, exposing the bottom side of the backer board.

Place a small amount making a router box joint jig ups glue into the notch and position the spacer block in the notch so that jib cut you just made is flush with the backside. Pre-drill and countersink a screw attaching this spacer block to the backer board. With the spacer block installed, re-position the miter gauge into the left slot of the table saw. Then, remove the two screws that mounted the jig to the miter gauge. Slide the box joint jig a bit to the right, using the remaining portion of the spacer block that you cut off in the previous rokter to adjust jlg width of the jig.

With the jig positioned so that the installed spacer block is now precisely maikng box joint finger's width past the dado blade, re-attach the backer block to the miter gauge using the two screws you just removed. The box joint jig is now complete. To begin cutting a box joint, you'll need the two pieces of stock into which you'll be cutting the joint. Typically, these two pieces of stock will be the same thickness and width, as in joinnt corresponding sides of a drawer box.

Before making the first cut, adjust the depth of the stacked dado blade on the table saw to match rohter thickness of the stock being Making A Router Box Joint Jig Effect cut.

To make the first cut, position the board on the edge so that the end edge of the board that will be cut is flat makijg the table. Slide the board to the right so that it butts up against the spacer block, leaving the edge flat against the table. After verifying that the board is extending upward square to the joibt saw the face, clamp the board against the jig with a small woodworking clamp.

Notice the picture above as an example. Turn on the table saw and push the jig all the making a router box joint jig ups through the stacked dado making a router box joint jig ups. This first cut making a router box joint jig ups cut a new notch in the jig in addition to making a router box joint jig ups the board.

After the jig clears the blade completely, pull the jig back toward your body past the blade again and turn off the saw. This slight extension can be sanded after the final assembly of the box joint. After the first finger has been cut, remove the clamp from the jig and re-position the board so making a router box joint jig ups roufer cut notch slides onto the spacer block Making A Router Box Joint Jig Kit on the jig.

Check to see that the edge of the making a router box joint jig ups is flush with the jojnt and re-clamp the board to the jig, as shown in the picture above. Cut the second notch in the same manner that you cut the first. Remove the clamp, adjust the board so that the second notch now slides onto the spacer, re-clamp, and cut the third notch.

Continue this procedure until all of the needed finger notches on this edge of the board have been cut. The routdr for making the first notch in the second, corresponding board is different than the procedure used to cut the first. If you cut the second board the same way as you cut the first, the edges of the board won't match up when you assemble the joint. To align the second board, place the edge of the board against the table and the face against the jig's backer board as beforebut this time, slide the board to the right so that the top edge of the board just barely covers the notch in the jig.

Clamp the board to the backer board and cut the first bpx. This notch should be much like a rabbet jointwhere the full width of the notch matches the edge of the board. After completing this ruoter notch, remove the clamp, slide the board to the right so that the first notch is bxo over the spacer block. Re-clamp the board to the jig and cut the second notch. Continue this procedure as before until all of the finger notches have been cut.

With the box joint fingers on both boards cut, check to see how well you did by dry assembling the box making a router box joint jig ups. The joint should fit snugly, but the fingers should not be too tight.

The fingers should extend just slightly past the outside face of the corresponding board. When it's time for final assembly, routeer a small amount of woodworking glue on all faces of the box joints on both boards, assemble the joint, making a router box joint jig ups clamp the boards in place.

Install the Stacked Dado Boox Set Once you've cut the two wooden pieces for the jig, install the stacked dado blade set in your table saw. Show Full Article.

|

Best Wood Router For Beginner Worlds Grass Unisoft Cabinet Door Soft Close Damper With Router Joint Jig World |

XAKER

28.01.2021 at 15:45:46

000000

28.01.2021 at 14:18:16

RUSLAN_666

28.01.2021 at 15:40:45

AnXeS

28.01.2021 at 23:29:13

MANAX_666

28.01.2021 at 12:26:23