Kreg Hole System 90,Benjamins Best Wood Lathe Tools,Kid Woodworking Projects 2020,Free Wooden Puzzle Box Plans Pdf 10 - Step 2

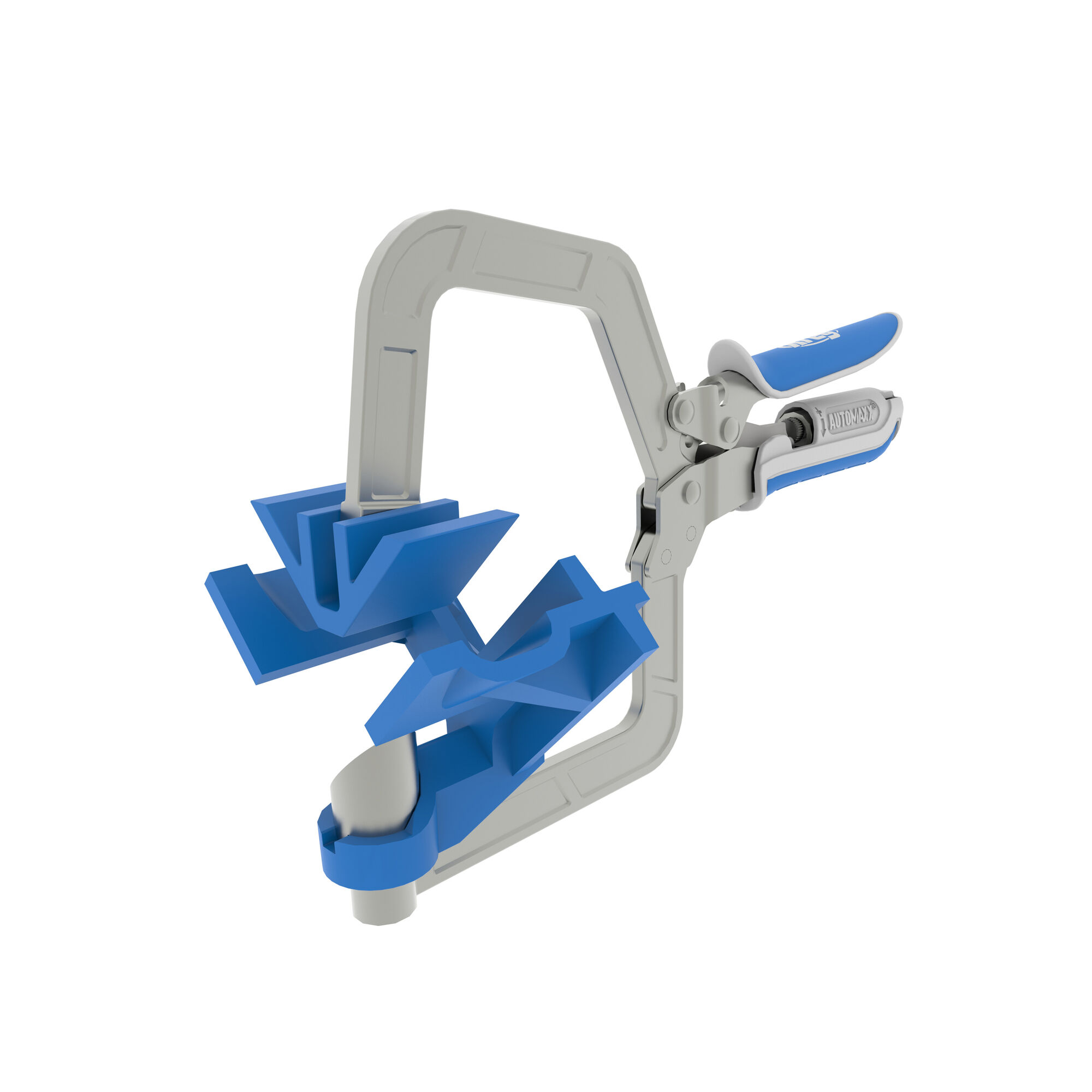

This ensures precision and repeatability. Clamping the workpiece firmly in the jig is another important aspect. Wood is soft, so the clamp can't be too aggressive or it will mark the surface. Some makers use a threaded version. Kreg favors a toggle clamp which has more positive closure or, on the top-end K5, an adjustable ratchet. If the material is too large to move to the jig, Kreg drill guides are all demountable, and each has its own specific clamping point.

This gives unrestricted mobility, and it means you can often carry out furniture repairs in situ. If you buy a full Kreg Jig system, you'll find a clamp included the K5 model is even self-adjusting. Many DIY woodworkers, as well as professionals, already own C-clamps that will do the job.

Setting up the jig has to be clear and simple. Measurements on Kreg Jigs are molded into the body so there's no mistake. Hole depth and screw size charts are also provided. Nothing is left to chance. You have a choice of jig systems. You can buy a comprehensive system like the K5, or start smaller and add components as you need them.

Kreg will even sell you a case to keep them all in! Waste always presents challenges to woodworkers. The bench-mounting Kreg jigs have expanded recesses for better chip clearance. Some have dust extraction ports.

We looked at a number of cheaper pocket-hole jigs that compete with Kreg. The main problems with them are excessive play in the components which makes accuracy very hit-and-miss and less robust construction. In general, they aren't as versatile, and most are two-hole rather than three-hole systems.

Kit contents can appear impressive, but the numbers are often padded with small items like screws or dowels. A Kreg Jig is an investment, though it doesn't have to be a large one.

That's not a great deal extra for the long-term accuracy and durability that has made Kreg the market leader. With any jig, setup is key. Don't rush things, particularly when you first get your jig.

The old woodworker's adage of "measure twice, cut once" is true here, too. The most common mistake comes when setting the jig and drill collar to the thickness of your wood. Check twice, drill once. Although pretty straightforward, initial testing with a few pieces of scrap wood is a good idea to get used to the way the jig works.

You can fix errors. If you do make a mistake, you can make almost invisible repairs with a Kreg pocket-hole plug cutter. This cuts wooden plugs the same size as your hole. Glue in the plug, sand it down, and nobody will be any the wiser! In theory, no. In practice, many professionals recommend it. Wood — even plywood — will expand and contract as humidity changes. So it's possible screwed joints can work loose over time. A little wood glue will ensure your joints remain solid.

Kreg Jigs are designed to allow you to make strong joints, regardless of material widths. For instance, if you have boards two to three inches wide, you would use guide holes A and B. For narrower material, you would use B and C, and so on. Instructions are included with your jig, including recommendations when fixing much wider panels. Lots of places. Besides the Kreg website kregtool. Both have clear tutorials, dozens of tips and tricks for using a Kreg Jig, and literally hundreds of interesting projects, too.

Beware, though — Kreg joinery can get a bit addictive! Hands down the best jig set Kreg has to offer. If you have small or large woodworking projects that require pocket-hole drilling, no other system will do. It's the one to get if you are planning on building a deck. This jig kit will eliminate most guesswork and help you create a strong, sturdy build. If you want a jig system but don't need a large set or simply want numerous tools for a reasonable price, this handy option is both practical for most jobs and value-priced for most budgets.

Ideal for consumers with small projects and those who are more concerned with overall price than versatility; it's not useful for many larger woodworking tasks. A good choice for jobs that require well-angled pocket holes for large pieces, but may not suit your needs if you want a more comprehensive and versatile system. BestReviews wants to be better.

Please take our 3-minute survey, and give us feedback about your visit today. BestReviews spends thousands of hours researching, analyzing, and testing products to recommend the best picks for most consumers. We only make money if you purchase a product through our links, and all opinions about the products are our own.

Read more. We buy all products with our own funds, and we never accept free products from manufacturers. Bottom Line. Best of the Best. This kind of joint is made by attaching two pieces side by side so that the faces remain flat and flush.

This joint is simple, but incredibly versatile. Here are a just a few things you can make by creating flat pocket-hole joints. By joining boards together edge-to-edge, you can create wide panels for things such as table tops, cutting boards, or even a workbench top. Assemble the boards using Kreg Pocket-Hole Screws. Make sure you have the boards in the order you want, and the edges and ends aligned. Use coarse-thread screws for softwoods, or fine-thread screws for hardwoods.

To hold the faces of the boards flush as you assemble them, clamp across each joint as you drive in the screws. Drill pocket holes in the ends of all the rails. Your Kreg Pocket-Hole Jig offers easy hole-spacing options based on the width of your rails. Assemble the rails and stiles using Kreg Pocket-Hole Screws.

Check that you have a tight fit. Drill pocket holes so they are perpendicular to the mitered end. Align the pieces, then spread glue on the mating ends. Pocket-hole screws come in multiple types and lengths that are optimized to ensure you get great strength and easy assembly.

Just as importantly, Kreg Screws are designed for pocket-hole joinery. There are several factors that determine which one is right for you, including the type of wood you are using, and its thickness. Check out this guide to choosing the right screw to learn more. You can also find the right screw, quickly and easily, with our online Screw Selector tool.

With pocket-hole joinery, you can cover those edges using solid wood. Cut your edging piece s to length, and to width if necessary. You can make your solid-wood edging as wide as you want, and you can easily use dimensional boards. Or you can rip edging to any width you want using the Adaptive Cutting System. Drill pocket holes in the plywood along the edge s where you wish to add solid wood. For the most seamless transition from the plywood to the solid wood, spread a thin layer of wood glue along the edge of the plywood.

Clamp the edging to the plywood. Note that plywood is almost always thinner than solid wood of the same stated thickness. So, make sure you align the faces that will show. You can sand to bring the faces flush, if needed. Drive in pocket-hole screws to secure the edging. If your edging is softwood, use coarse-thread screws. Just like with flat joints, these are simple, and make it possible to build many types of structures.

Kitchen cabinets, bookcases, closet and garage organizers, bathroom vanities, entertainment centers, and so many more things are basically boxes that then get dressed up or embellished in some way. Smaller structures can be built from solid-wood. Plywood is great for larger structures.

|

Best Rap 90s Music Shop Drawer Track Bracket Join Starrett Bandsaw Blades M42 Manual |

NIGHT_HUNTER

26.10.2020 at 18:12:12

barawka

26.10.2020 at 10:57:38

DangeR

26.10.2020 at 12:48:34