Free Cnc Router Sign Making Software On Mac,Lathe Tools Tips 2019,Pen Turning Blanks Wood Light,Carpentry Shop Of America - Videos Download

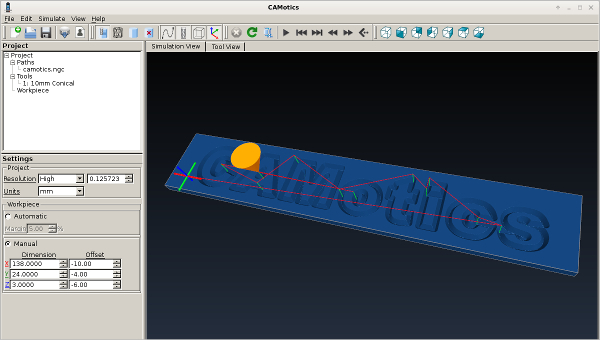

G-Simple is a simple CAN package is for 3-axis machining. It applies various filters for managing library tools, removes excess materials, drill adjustments and text engraving. PyCAM generates toolpath for 3 axis machining.

This supports many toolpath strategies for 3D and 2D models. It runs on Linux. Scan2CAD converts raster designs to vector file format in a few seconds. The raster and vector editing suites can be used to create the optimal vector image for any CNC design.

It supports 33 file types and comes with batch processing. There are two types of CNC control software. One control software built into your machine and other is PC-based software. If you are using a CNC machine such as HAAS Vertical Machining, you would require a complete solution complete hardware and software solution that is built into the machine. In this, you can transfer G-code directly to the machine. The Mach series works on most Windows PCs.

The latest version is Mach4. This is customizable. This can control up to 6 axes of a Machine. This software is very inherent and customizable. Mach3 is one of the most well known and widely used CNC machine controllers.

LinuxCNC is completely open-source. This software runs on Linux. This can control up to 9 axis. This supports rigid tapping and cutter compensation. This helps in numerical control of machines. TurboCNC can control up to 8 axes of motion, and it provides fully parametric programming. This is fully functional shareware. Universal Gcode Sender is widely used software used to convert arcs to line segments. This has configurable G-Code optimization, duration estimates, support cross-platform, 3D G-Code visualizer and many more to add.

Caliper2PC is a digital readout for milling machines, lathes, and other tooling machines. This is a very adaptable and user- friendly software. CNCZeus is the advanced low-cost machine control software. Perfect for large professional machines.

Its features include cutter composition, digitizing probe, optimized assembly language and more. Woodworking is the most widely used application of a CNC router since it offers a lot of benefits and flexibility when working with wood than with any other material.

For such users, we have reviewed the best woodworking software since there are a lot of things to consider when getting your first woodworking design software that will allow the functioning of tools and elements that you want. Both G-code and M-code carry different information. A G-Code Geometry is related to the placement of the hardware relative to the workpiece like cutting tasks and determining units.

A CNC machining is not hard to learn. But once you get the hook of it, everything will be easy with time. By using a CNC machine software, you can take complete control of all the processes involved in the manufacturing and monitor end to end process. The production process of a CNC router reduces the number of steps required to make a part. The entire fabrication process is automated and by choosing the right CNC software at each step, you improve the efficiency.

The same components can be reproduced and replicated as many times as required without compromising the quality. A single person can supervise multiple CNC routers with ease if he gets accustomed with the cnc software. There is no need to make a prototype model. You can directly simulate the requirements in the software. There are a few limitations associated with CNC.

Based on the age and sophistication, CNC machines have limited capabilities in control and drive systems. Most CNC control softwares only interpret straight line movements and circular arcs. In many cases, the arcs are restricted to the principal XYZ planes.

The demand for the CNC router with immense capabilities is still on the rise. Though it has many limitations, its advantages outnumber them.

Hence, CNC is here to stay long and enhance its capabilities now and then. I am a beginner with a style cnc router I am doing memorial stones and would like to know what is the best software out there for a beginner? Thank you. The software has been discontinued by Autodesk since , however some of our users were still able to download and use it from opensource resource. But we will now add a line next to it with some of the alternatives to ArtCam.

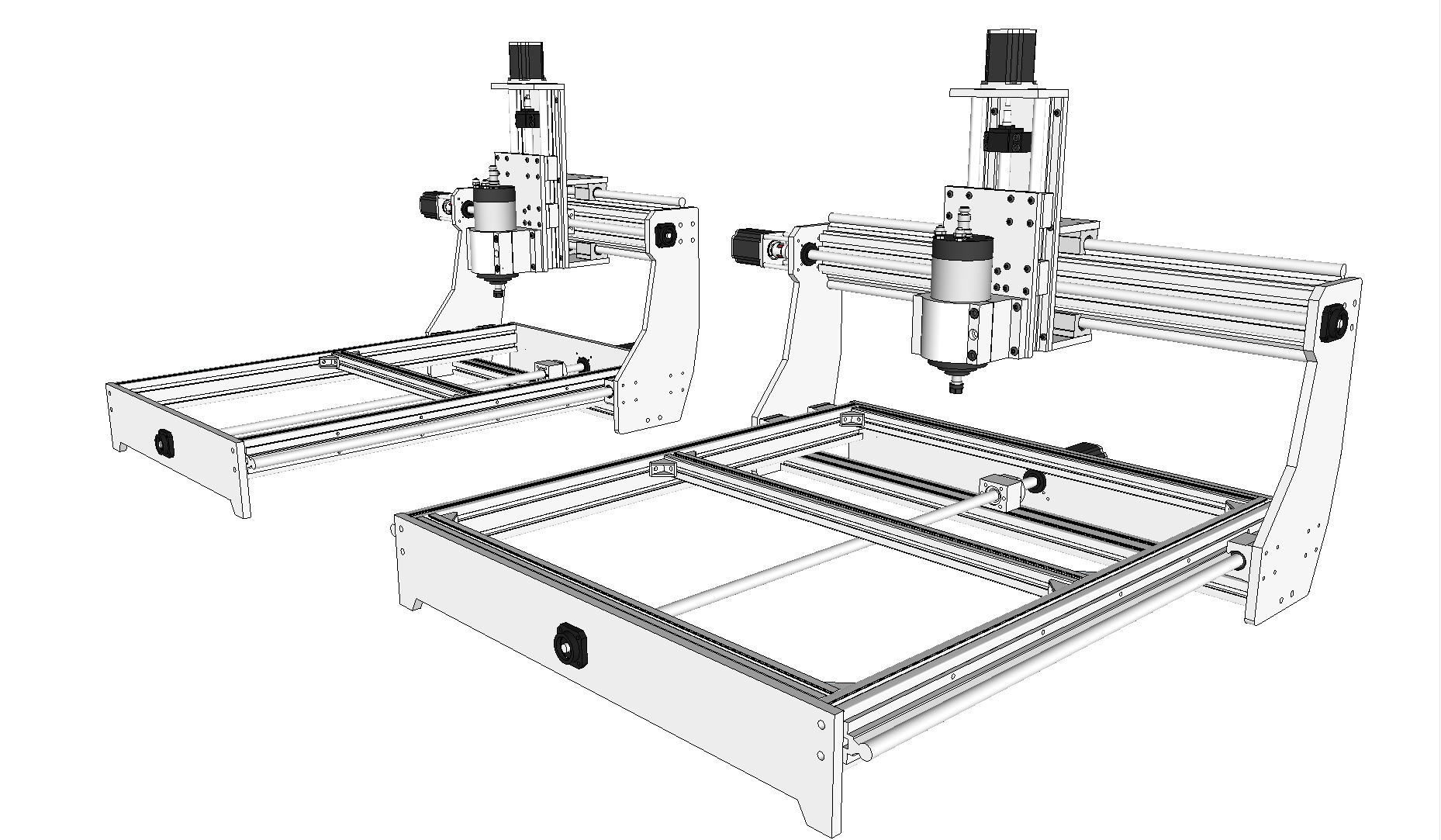

Let me know if you have any recommendations for us. Hello — I am in the process of purchasing a CNC router that engraves on stone and the images are quite large. The apparatus is special as it is the framework without a platform and it is placed on a railing system that lies over the stone and engraves.

Because the images are quite large, sometimes larger than the apparatus, I am looking for a software that allows you to pick up the apparatus and move it while keeping place of where the image has stopped and will start up again to finish the engraving. Can you recommend a software that will accomplish that?

You can use Autodesk since that has better usability and ease of making complex patterns in an easy way. Hello Thank you for this wonderful article! I am in the market to buy CNC machine to produce custom furniture with lots of carvings and engrave in the wood including custom design for the fabric , if you were me what machine would you buy and which softwares would have been your choice for CAM and CAD?

Regards Anna. Thanks for dropping by, Sure so if I was looking for a CNC machine that can make custom furniture which means there will be a lots of operations that will involve wood as a material.

Hey great article thank you for the excellent information.. I have a a I have upgraded the spindle mount and spindle from to I lost the CD for grbl for it.

Would you suggest I use Pycam as my cam sorfware. Or could I use easel? Any advice would be very appreciated. Thank you Tamati. It is just a cool program that will allow you to makes some really cool projects to make family and friends happy.

PhotoVCarve machines dark areas in a photograph with wide groove and the lighter areas to have narrower ones. The software automatically calculates the toolpaths based on the cutter selected and maximum depth of groove required. But when back lit transform into stunning 3D pictures with depth and detail that cannot be seen in a flat 2D photograph. Photo V-Carve before stain. It is easy to use and allows you to quickly do serious work, which in my opinion is the mark of good software.

You can also take work created in any of the other Vectric programs and enhance them in VCP. You can create a D bas-relief in Cut3D and then bring it into VCP , add VCarving letters and cut out a profile around the project or cut the project loose from the backer board. I think these programs are what most Makers would buy and use.

Also, after I finish introducing you to the products I plan to recommend which products I would buy in what order if you are on a budget or if money was not a consideration. The flagship of the Vectric line is Aspire.

Aspire is a no holds barred, full blown CAM package. It is designed to give the professional C. Machinist the power to create unbelievable products at an affordable price relatively speaking. Aspire will do everything VCarve Pro will do. It will also allow you to create 3D models from a a vector outline.

You could for instance take a standard line drawing clipart and convert it to Free Cnc Router Sign Making Software Video 3D automatically. Aspire also lets you modify every feature of the design independently. Lofting, sweeping, Blending sculpting, depositing….. If you have a serious need for this kind of power, you will be glad you looked at Aspire.

One of my first attempts at sculpting with Aspire. The choice of software is strictly a matter of personal choice. I use the products from Vectric because they meet and exceed my needs. The software is constantly being updated and improved. Vectric has a very active users forum which can help answer many of your questions.

The Vectric staff also is quite active and it is rare to see a question go unanswered for more than an hour or two. Vectric over-delivers when it comes to software. If you would like to receive more CNC related information check out our free newsletter. You can follow any responses to this entry through the RSS 2.

The WinCNC offers a control interface that plugs directly into the computer motherboard that will output standard step pulses to be delivered to industry standard drivers such as ours.

Click the link to respond: How do you zero the z axis using a plate with the planet-cnc software and your USB controller? Yes, all of the software we sell on this website will work on windows Click the link to respond: will any of your software work with Windows Only input devices mouse, keyboard, monitor and software are required to be purchased separately, to have a complete ready to go system.

Our electronics and machines are compatible with all non-proprietary CAM programs. Click the link to respond: I am interested in purchasing your 4 axis combo package. Is it compatible with MeshCam.

So, Free Cnc Router Sign Making Software Guide there is no problem using SketchUcam. The parallel breakout board can run under Windows or Linux OS and the computer must contain a parallel port. This software is well made and will provide great functionality.

The planet-cnc software delivers instructions to the microcontroller on the board and the microcontroller will send out the pulse trains needed to move the machine correctly. There are two main alternatives if you want to use the mach3 software: First, get a parallel port card and add it to your computer and get a parallel breakout board. Second, if you have a laptop, or really want to use the USB as the main interface for controlling the machine, you will need to get the smoothstepper board which works with mach3.

The price combination is much higher than the USB controller with planet-cnc, but will work with Mach3. Additional Information: Additional Information: Additional Information: The planet cnc controller can be prone to electrical interference and has been known to cause such problems. In the first instance try to use a quality double sheilded USB cable, hopefully this will fix your problem. Alternatively you may need to sheild your limit switch, estop and or motor cabling.

My pick is that a quality USB cable will fix it though, worked for me. How can I determine if the 4th axis you offer will be compatible with my machine?

|

Remove File Cabinet Lock Cylinder Zoom Things To Make With Wood Lathe Zero Kreg Kms8000 Manual Unit |

Victoriya

02.03.2021 at 13:51:15

rovsan

02.03.2021 at 12:10:56