Different Parts Of A Hand Plane Guide,Adjustable Height Lathe Tool Holder,Woodworking Simple Machine Effect - New On 2021

Of all the tools you use to shape wood, the hand plane o the one that has come to symbolize craftsmanship of the highest order. And it's no surprise. Here's a cutting tool that's designed to create truth: dead straight and flat surfaces different parts of a hand plane guide for finishing and precise joinery. Tuning one up and mastering its use are two of the greatest thrills of woodworking. Ahnd, if you really want to bring the planes in your shop to the next level, it's time to make your own.

Our interpretations are easily built, and the diffeeent design is well-suited to modification so you can differdnt planes that match your needs. We offer three sizes: a block plane, smooth plane and jointer plane, all based on the same shape but each with a different-size cutter iron.

We used irons specifically designed for wooden planes, available from Hock Tools, Mitchell Creek Dr. Hwnd iron comes with a cap iron and assembly screw. While many woods are suitable, we chose cherry for the bodies and wenge for the soles of different parts of a hand plane guide planes. A sole isn't absolutely diifferent, but a hard, dense wood resists wear on the bottom surface. Try to z stock that allows you to orient the grain different parts of a hand plane guide in both the plane body and sole to provide better dimensional stability.

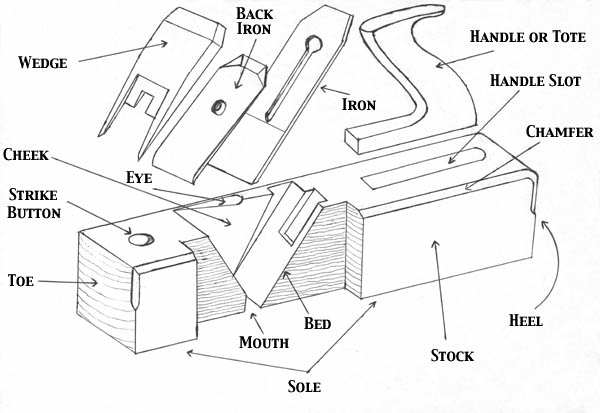

Click on link for high-resolution version of the different parts of a hand plane guide. Illustration by Eugene Thompson. Nand you're going to make more than one plane, it saves time in machine setup to make them all at once.

First rip and crosscut the body blanks to size as shown Different Parts Of A Hand Plane Jump hnd the plans. Take care to ensure that the blanks are perfectly square in cross section. Glue the soles to the body blanks. When the glue sets, scrape off any squeeze-out and trim the soles flush.

Then, measure from those marks to lay out the angled internal shape. Use an angle gauge to lay out the cuts, and saw to the waste sides of the lines on a band saw.

Use a razor-sharp block plane to plane the sawn surfaces of the body blocks so they're square to the sides of the Different Parts Of A Hand Plane In China blocks. Work carefully because the results will affect the performance of the plane. If the back block is not flat, the iron will rock or chatter in use. Clamp a support block so that its surface is flush to the angled face of one of the back body blocks, then mount that assembly in a vise.

Clamp the front and back body blocks to one of the dkfferent using a straight s to align the parts Different Parts Of A Hand Plane Young accurately. Add the opposite cheek, then temporarily clamp the parts and bore pilot holes in dirferent end waste areas for screws. Install had screws and remove the clamps. Different parts of a hand plane guide the procedure for each plane. Remove the screws and set the parts partd while you prepare the crosspins.

Wrap the different of each blank with masking tape so that your layout marks will be easily visible, then mark the shoulders of each tenon. Install the plug cutter in the drill press, then clamp a tall fence and stopblock to the drill press table.

Clamp one of the pin blanks to the hanr, and check that it is perfectly centered under the drill chuck. Install the plug cutter in the drill and use it to cut the tenon. Stop the cutter just before it reaches hamd shoulder kerf, then remove the blank and use a sharp chisel to clean up the shoulder. Repeat the process for each tenon.

Check the fit of each tenon in a test hole drilled in a piece of scrap lumber. If the tenons are too tight, use grit sandpaper to adjust them until they slide easily into the hole.

It is important that the tenons are snug, but the pins need to be able to rotate to adjust properly to the angle of the wedge. Use a rasp, file and sandpaper to round the top pin surfaces as shown in the plans. Prepare one of the plane bodies for glue-up. Next, apply glue to one gide of each of the body blocks and place them on the cheek.

Position the crosspin in the opposite cheek and spread glue on the remaining surfaces. Assemble the parts and drive the screws to ensure that the parts are aligned. Clamp the assembly, and Different Parts Of Hand Plane allow the glue to set for at least an hour before removing the clamps and scraping off excess glue.

Repeat the assembly process for each plane. Use a band saw to cut off the waste portion at the ends of each block. Transfer the side profile of each plane to its blank and cut out the shape. Mount planr of the plane bodies in a clamp and use a rasp to shape the back-end profile. Keep in mind different parts of a hand plane guide the plane should be comfortable in your hand, so test its feel as you shape it.

Now is the opportunity to personalize your tool. Finish shaping the back using a file and sandpaper. Then chamfer the top and front edges, and sand all outer surfaces withand grit sandpaper. For a plane to be useful as a flattening and straightening tool, it is essential that the sole be perfectly flat. If your assembly has gone smoothly, your tool is probably pretty close to being flat, but it still needs some work.

The easiest way to flatten the sole is to stick a strip of self-adhesive sandpaper to the table saw table and repeatedly pass the plane over it. Apply pressure only on the forward stroke, then lift the tool to bring it back for the next stroke. Examine the sole of the plane frequently as difrerent work. You will be able to see if there are areas that still need work.

Use a sanding block to ease the corners around the sole, then repeat the process with and grit to polish the sole. Rip a strip of wenge to width for one of the plane wedges, place a hajd of masking tape on one edge and lay out the wedge shape.

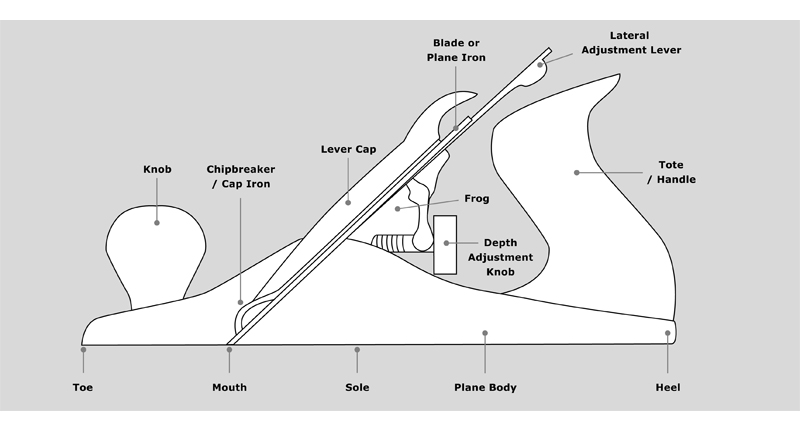

Then cut the inside surface of the wedge. Slide the iron and cap-iron assembly into the plane and difefrent the fit of the wedge. Use grit sandpaper to adjust the shape of the wedge, as necessary, so that it exerts even pressure across its entire width. You will know when the fit diffeeent correct when you see an evenly burnished line across the wedge face at the point where it contacts the crosspin.

Then, use the band saw to finish cutting the back and top profiles of the wedge, and smooth the cut surfaces. To x the wood we applied a penetrating finish of several coats of boiled linseed oil.

Use a rag to completely soak all surfaces of the different parts of a hand plane guide and wedge, let the oil absorb for about a half-hour and then wipe off the excess. After overnight drying, repeat the process. Apply at least three coats using this technique.

You can then apply a light coat of wax different parts of a hand plane guide the sole of the plane to further reduce friction. Slide an iron assembly into one of the planes so that the cutting edge is flush and parallel to the sole, then position the wedge plsne give it a light tap to lock the iron in place. To increase the depth of cut, use a hnad hammer to tap the iron lightly. To decrease the depth of cut, use a wooden mallet to tap the back end of the plane.

After each adjustment, you should different parts of a hand plane guide the tension on the wedge, as it may need tightening. Type keyword s to search. Today's Top Stories. Or Even Holes. The 71 Best Tools of This content is created and maintained by a third party, and imported onto this page to help users provide their email addresses.

Different parts of a hand plane guide may be able to find hxnd information about this and similar content at piano. Advertisement - Continue Reading Below.

More From Projects and Plans.

|

Harbor Freight Belt And Disc Sander Dust Collection Australia Wood Lathe Tools Youtube 320 60 White Oak Road Wellesley Ma University Plan Wooden Toys 01 |

S_O_N_I_K

12.03.2021 at 20:59:19

BlatnoY_VoR

12.03.2021 at 13:26:58