Diablo Up Spiral Bit Filter,Reclaimed Wood Projects That Sell East,Best Rap Love Songs 2020 Full Movie - Step 2

Logging in Remember me. Log in. Forgot password or user name? Header Ad. Freud blades vs Freud Diablo blade differences. Posts Latest Activity Photos. Page of 1. Filtered by:. Previous template Next.

Freud blades vs Freud Diablo blade differences , AM. I need to replace a 12" miter saw blade. I have noticed that in general, Diablo blades are a bit less expensive when compared side by side. I never have found a definitive difference and appreciate your insights.

I have been contemplating a new blade or getting this one fixed. I measured a board, moved the tape measure back but didn't take into account how far out toward me the saw blade comes. The blade hit the steel hook. Ruined a very good rule too. Last edited by leehljp ; , AM. Hank Lee Experience is what you get when you don't get what you wanted!

Tags: None. No expert here, but I've been under the opinion that the difference is simply that it is less expensive by design.

But, I really don't know. I did do a Google search and found the following Freud "quote" from a post made on the Saw Mill Creek forum by a Mr. We make our own micrograin carbide in numerous formulations that represent various degrees of hardness. The carbide is selected depending on the intended application the hardest is used for laminates the softest for ripping as are the tooth angles and tooth quantity. The steel for the blade plates is all the same grade. The brazing is all the same.

We also offer the most selection of specialty blades in this line. These have the most appeal to professionals who need to get a lot of sharpenings out of a blade and to artisans who need specialty blades for their projects. The TK and Diablo lines are very similar.

Both are thin kerf blades and the tip thickness is the same. The key difference is in the way we market these blades. The Diablo line has blades intended for purposes like framing, siding, decking and general home improvement and is packaged and promoted in ways that appeal to contractors and DIYers. The TK line has blades for similar purposes as well as laminate blades but is sold with different or no coating and different packaging and POP material to appeal more to woodworkers.

Do professional woodworkers shop for blades at Home Depot? Probably some do and they can get excellent performance from a Diablo blade for a lot of their uses but with a shorter overall life and lower cost due to the tip thickness. Same with the TK blades at Lowe's. Why not compare a TK or Diablo blade to Forrest? Consider this analogy: Toyota cars and Lexus cars share a lot of the same components and are made by the same company.

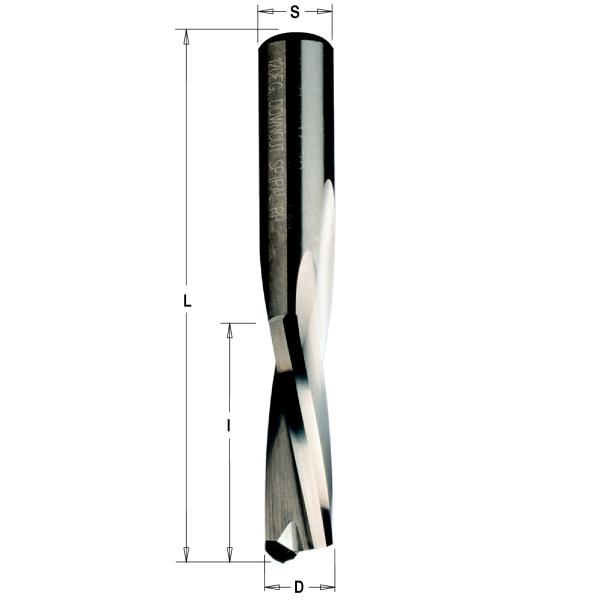

Would you compare a Camry with a BMW? The difference between ours and Forrest's is that ours is made by computer controlled, super modern equipment and theirs is made by hand. Spiral bits look like drill bits and are most often made of solid carbide, so they are super sharp and leave a superior cut on wood. Two flutes ground around the body of a spiral bit smooth vibration by spreading the cutting action over a longer edge.

With their drill-like point, spiral bits are also better for plunge-cutting. The new solid-carbide spiral bits come with some disadvantages. The first is that the cutters are expensive. But because most spiral bits are ground on the tip end of the flute, somewhat like a drill, you can plunge straight down as far as you like, without stopping. On most straight bits there is a space above the web, between the cutters, where no cutting takes place during a straight plunge because there is no cutter overlap.

Chuck a straight bit into your drill press and plunge it into a piece of wood. To go any farther, the bit has to abrade the wood away in this middle area.

You just have to sweep the router while you are plunging. Solid-carbide spiral bits are becoming increasingly popular because they make a very clean cut. But they have many limitations compared to the straight bits that have been popular for years. All spiral bits make clean cuts. This veneered plywood shows the effects of the three types of spiral bits on the top and bottom edges. The three basic cutter configurations for spiral bits are up-cut, down-cut, and a combination of the two, known as a compression bit.

A down-cut bit sends the chips downward; an up-cut bit sends them up to ward the shank. On a router table, all direc-tions are reversed. Besides directing the chips, the advantages of these configurations are best illustrated by the quality of cut, especially on veneered plywood see the photos above. A down-cut bit will leave a clean edge on top but a ragged edge on the bottom; an up-cut bit will accomplish the opposite.

This is great until you want to cut a dado with no tearout on the face. A down-cut bit will leave a clean top edge, but it sends the chips downward, into the dado where they have no place to go. You can make this cut, but you have to take it slower than usual to give the chips a chance to clear. For woodworkers who work with A-grade veneers on both sides of the stock and must have a clean edge top, bottom, and middle, the compression bit is a good choice.

It has an up-cut configuration on the tip of the bit and a down-cut spiral ground on the shank. By lining up the bit just right, you can get a superior edge across the entire thickness of the wood. Router-bit manufacturers have difficulty making solid-carbide spiral bits with cutting diameters larger than their shanks. Straight bits, on the other hand, go through dozens of fractional sizes, all the way up to 2-in. Depending on the job you have in mind for your router bit, straight bits also come in a variety of cutter lengths.

So you can buy close to exactly the length of cutter you need. Straight bits also have a huge advantage over spiral bits when it comes to template routing, because you can buy them with guide bearings.

And those bearings can be mounted on the tip of the cutter or on the shank of the cutter, depending on your needs and your template. The bearings are made for a variety of cutter diameters and lengths. With their superior edge cut, spirals make great template cutters when used with collar guides. But when it comes to bearing-guided bits, spirals seem to be available only with bearings mounted on the end of the bit. Shank-shod, bearing-guided, solid-carbide bits spiral bits with the bearings on the shaft end of the bit , which would permit template routing with the template on top of the work and trim cutting through only part of the work face, are not available.

Some woodworkers like to sharpen their straight bits, although I find it difficult to get it right and always send out my bits for sharpening. Carbide-tipped straight bits usually have enough carbide thickness to be reground four or five times, and the tech- nology to do so is common. A few services claim to be able to sharpen spiral bits. To me, this translates into a substantial loss. Spiral bits might stay sharp longer than straight bits, but even so, the cost of using spiral bits will always be higher.

Spiral bits work incredibly well in the production environment and especially in CNC computer numerically controlled router industrial applications. But in a hand router, their use sometimes imposes unusual risks not associated with the equivalent or bigger straight bits. The down-cut spiral bit's screw-driven forces are sufficient enough to pick the router up and twist it out of your hands—with no warning.

I know, because it has happened to me. On end grain the spiral bit is getting even more traction, so the risk is even greater—a pity, too, because a sweet end-grain finish is attractive. The up-cut spiral bit can have the opposite effect.

|

Walgreens Pumpkin Carving Kit Walnut Dowel Rods Lowes 60 |

Bratka

08.02.2021 at 16:26:37

cedric

08.02.2021 at 21:51:47

Tanchor

08.02.2021 at 19:43:24