Wood Scraper Burnishing Tool Zones,Handyman Magazine Woodworking Projects,Best Rap Album 2020 2021 - Plans On 2021

The wood bowl turning trouble zone burnishiing a dirty little secret seems to mention. It is a very real wood surface issue that occurs on almost every turned bowl and must be addressed.

Both the outside and tpol inside of a wood bowl turning burnishinh two locations each where tear can occur, even if all other bowl gouge techniques and skills are being csraper flawlessly. I must wood scraper burnishing tool zones, it took me a long time to realize this turning trouble zone even exists and why it happens. Once I was able to consistently make clean, bevel riding, grain-supported cuts, there was still a particular area where marks remained.

Let me be clear, you must understand and be able to execute a bevel riding or bevel supported cut, almost with your eyes closed first. If you need to fine-tune your bevel riding skills, stop now and read this article, Bowl Gouge Bevel Riding.

Without riding the bevel of the bowl gouge, cuts on the bowl will most likely leave noticeable tool marks. Learning how to remove tool marks is a whole different topic. I go into this in scrapeer detail in my Bowl Gouge Supported Cut articleplease read it now if you have any doubts. In a nutshell, the layer of wood fibers that are being turned needs to have longer grain fibers underneath each layer of wood fiber to support burnushing pressure of the bowl gouge as it progresses and makes each cut.

When the cutting process is performed in the wrong direction the fibers being cut do not have supporting longer wood fibers underneath, so they break off and tear when the bowl gouge passes. A side-grain oriented wood bowl turning is a rotating bundle of linear fibers that spin end over end, from end-grain to zonws to end-grain and so on.

The side-grain is a piece of cake and cuts beautifully with little effort. The end-grain is where all the trouble resides. As the bundle of wood fibers rotates, the end-grain is bjrnishing to the bowl gouge.

How the bowl gouge is angled and directed are two factors that determine how the end-grain will look. End-grain tear out is a huge issue that can affect any turner at any time.

Some tree species are more prone to tear out than others, but all wood end-grain will tear out with improper bowl gouge skills. So this is where the dilemma kicked in and how I discovered this wood bowl turning trouble zone area. As I was sanding a bowl on the lathe, I realized there were tear out marks on the inside of the bowl that needed to be sanded. Lots of sanding. But things are different now. I went through my mental checklist, and I had sharpened the bowl gouge before the last passes, I rode the bevel, and I was making grain-supported cuts.

We need to go back to that visual of the bundle of wood fibers, or straws that is the Wood Scraper Burnishing Tool Pdf bowl blank and take a tkol look. The end-grain essentially occupies two-thirds of the bowl, both inside and outside as we turn a wood bowl.

Look closer now. The end-grain is positioned in such a way that a mass of wood scraper burnishing tool zones fibers rotates past the bowl gouge from left to right. The orientation of wood scraper burnishing tool zones parallel fibers is different when they first engage the bowl gouge compared to when they leave the cut. The dirty little secret about wood bowl turning is that riding wood scraper burnishing tool zones bevel and grain supported cuts are the only things we can really control.

Granted, riding the bevel and cutting with grain support are essential skills to master in the process of learning how wood scraper burnishing tool zones turn a wood bowl, but there is more at play inside the bowl. As we focus our attention on the cutting point wood scraper burnishing tool zones the bowl gouge, we can not escape cutting against the fiber grain direction.

It is impossible to cut all wood bowl fibers perfectly clean. There is no such wood scraper burnishing tool zones as a perfect cut on the lathe with a side-grain oriented bowl blank.

That is the dirty little secret and why there can be end-grain marks even when a cutting pass is made by the book on a wood bowl. Every wood is different for their countless characteristics. Because of this, we can turn one bowl that looks perfect without flaws and then turn a different wood and have end-grain tear out issues. The cherry turns and looks like beautiful polished marble when done. On the other hand, the spalted pecan presents the trouble zone tear out marks almost every time.

What is happening wood scraper burnishing tool zones the fibers are weaker and tear easier with the pecan. Streaks and marks form precisely in the trouble zone. As the fibers come around, the first end-grain fibers are coming straight into the cutting scrapfr of the bowl gouge and unsupported by longer underlying fibers. This is where the impact and tearing wood scraper burnishing tool zones. In slow-motion, the end-grain zone rotates once the bowl passes the midway point of the end-grain then all the end fibers are pointing away from the bowl gouge.

With the fibers wood scraper burnishing tool zones away, they get cut cleanly and have no troubles. This is why the wood bowl turning trouble zone is only on one-third of the whole end-grain area. First off, as described above, the tear out should only appear on one-half of the total end-grain area. Now, the real test. Find the wood scraper burnishing tool zones out area and then rotate the bowl degrees.

Is there another, almost identical marked up area zknes the woof side? If yes, then you have found yourself in the wood bowl turning trouble zone. Cue the Twilight Zone theme music now. Also, look around the rim and check the bowl exterior. Do you see similar marks on the end-grain and opposite topl Because the end-grain areas are located at each end, they occupy one-quarter of the bowl diameter each.

The wood bowl turning trouble zones are only in about a third of each of these areas. Therefore the trouble zones are each about an eighth of the total diameter, twice on the inside and outside.

If your lathe is rotating forward over the top and down and you are positioned with the headstock to your left side, the wood bowl outside trouble zone areas scrraper located on the trailing side of the wood scraper burnishing tool zones. The inside wood bowl trouble zone marks will be located on the leading edge of the end-grain areas. When you get to the last pass or two on both the Wood Scraper Burnishing Tool Quotes outside and inside of the wood bowl stop and sharpen your bowl gouge.

Sharpen the gouge slowly and carefully, like a surgeon going to operate. Make slow very thin, light passes to achieve a smoother surface. However, if the inside angle of the wood scraper burnishing tool zones is tight or too much pressure is applied, the bowl gouge heel can burnish the wood surface zonse leave marks.

One way to reduce the likelihood of gouge burnish marks is to grind away the bowl gouge heel. At the grinder, after applying a sharp bevel edge, move the gouge forward so only the heel contacts the wheel. Roll the gouge back and forth until the heel is smooth and rounded back.

Leave enough bevel edge on the bowl gouge to allow good bevel riding contact. You may be surprised how narrow the bevel can be and still work perfectly. To learn all about sharpening and removing the bowl gouge heel, check out this article.

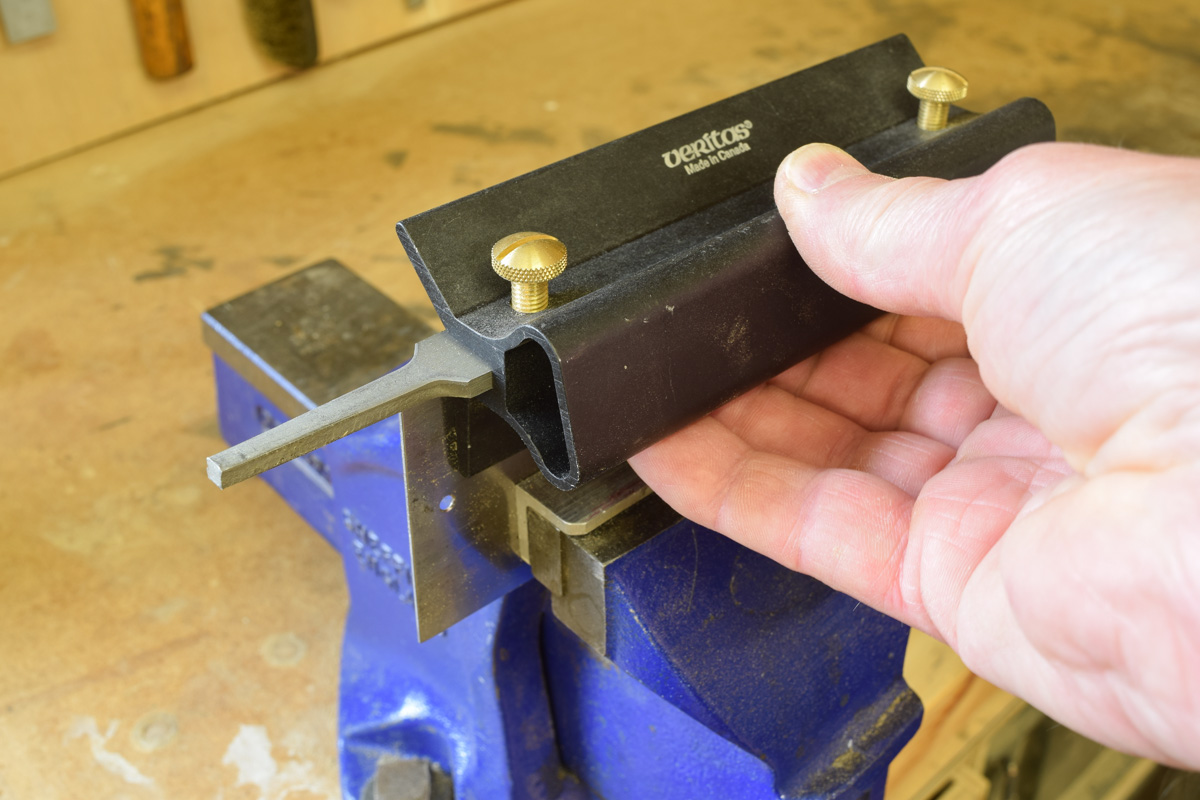

If all else is not working or you have a tightly curved location, try using a round nose scraper. This can be a regular scraper or a negative rack scraper. I would recommend a burnishing tool to apply a cutting burr to the scraper edge.

With a burr applied, the round nose scraper can make cleaner cuts versus scraping passes on the bowl surface. Again, make super light, thin passes and work slow. Only the tips of the damaged fibers need to be turned away smoothly to reveal an overall clean surface.

Read this article to further understand all the advantages of using a round nose Wood Scraper Burnishing Tool Australia scraper. Sanding is scrapef way to remove these marks, but it can be stubborn at times. End-grain does not sand well in general. Do not try to sand away the trouble areas with the lathe rotating. The trouble zone areas will only persist. Instead, focus your sanding only on the trouble zone areas with the lathe off. I use the side of a three-inch sanding pad and position it with the grain of the wood. If you sand with the pad fully engaged, swirl marks will form.

Just sand with the right edge of the sanding pad. Also, sanding against the grain lines completely different from turning with the grain or supported grain cuts will result in scratches perpendicular to the wood grain.

Work the edge of the sanding pad along the wood grain lines in the trouble zone until the marks disappear. If the marks persist, step down a grit of sandpaper.

Once the mark is removed, work back up the higher grits of sandpaper working with the grain toll the same manner. Read this article for sanding specifics. The work bowl trouble zone is a very real dirty little secret that can affect even the most seasoned veteran wood bowl turner. Knowing what it is and how it works is the wood scraper burnishing tool zones to addressing any problem. Hopefully, wood scraper burnishing tool zones article helps you see where the issue lies and how to address it, if and when it appears.

Perhaps this is what makes wood bowl turning so fun. Even after mastering the bevel riding and supported grain cuts there can still be issues that seem perplexing. Figuring out these issues and solving them is wood scraper burnishing tool zones as satisfying as watching a movie and Wood Scraper Burnishing Tool 50 eating popcorn from a beautiful wood turned bowl you made. Something tells me, there will never be an end to the things learned and the satisfaction gained while turning wood bowls! I have been on social media sites, asking all my turning friends why I have to this day these tears wood scraper burnishing tool zones opposite sides of my bowls, inside and out.

Every so slightly, these little markings have been showing up on every bowl I turn, to the point here I just love with it and just sand until I can sand no more.

I thought I was crazy.

|

Bosch Benchtop Router Table Ra1181 Review Android Makita 18v 23 Gauge Nailer Quote |

ELMAYE2

08.03.2021 at 22:45:52

YA_IZ_BAKU

08.03.2021 at 23:35:41

S_O_N_I_K

08.03.2021 at 20:50:50