Wood Gable Vent Plans Model,Under Shelf Drawer Nz Test,Delta Belt And Disc Sander 31 460 No - Videos Download

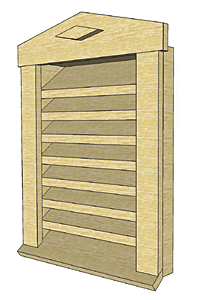

Secure the second louver in place with three nails on each side. Caulk all the joints on the louvers and the frame. Let the caulk cure. Prime and paint the gable attic vent especially while you have access to the back. Flip the gable vent frame over and cut a piece of wire mesh hard cloth to fit onto the back of the vent frame.

You can use any shape you like as long as it fits over the rectangular attic vent. The shape is simply created by attaching a frame to the front of the gable attic vent.

I chose the diamond shape since the original house had diamonds. Using the original house vents as my template, I cut Miratec trim into the same diamond shape. Connect the frame using wood glue and nails. Then secure the decorative frame shape to the gable vent with trim nails. Secure the gable vent inside the house framing using trim nails or screws.

The shape frame will sit on top of the house sheathing. Be sure to install house wrap or flashing behind the shape frame, but not over the vent. A drip cap is installed on top of the shape frame to prevent water from seeping inside.

Then the siding is installed. Finally the painters should caulk around all the seams where the gable attic vent meets the siding. Not bad considering the original gable vents were years old! I consider it a win being able to keep the original architectural feature and hopefully allow it to last another years or more.

Did I mention I had to build five decorative diamond gable attic vents? The house had three gables on the front original section of the house…. Let me know if you found this tutorial helpful in the comments. It only takes you a minute, but your comment helps keep me motivated. I hope you are enjoying these tutorials from the Saving Etta house. If you are just visiting this website, you might want to read the entire Saving Etta series!

It was a monumental undertaking did I mention it was my first house rehab? Glareat idea! This post gave me courage and inspiration for replacing my boring rectangular vent.

Thanks for sharing, and thanks for saving and restoring historical homes! Thank you! Sincerely appreciated. John G, Hollis, NH. Your instruction photos and the explanation are great! It makes your project easy to follow and easy to do. Thanks for that. If you measure carefully and cut with a table saw, you should be able to get two vanes from each board, assuming you are using 1X6 cedar fence boards.

These will be the stock cut for vanes later. Cut the face frame 1X4 treated southern yellow pine in images, used for strength, not appearance to the sizes and angles established from your layout.

A miter saw is helpful in getting accurate angle cuts. Assemble the face frame using finish nails or screws, then test fit on the gable where it will be installed. You may want to scribe the inside dimension while doing this to make cutting the hole in the siding easier later on. Cut the louver vane frame, again, using the layout for lengths and angles.

Attach the vane frame to the face frame, caulking the seam with a waterproof sealant and using rust resistant wood screws. Cut a compound angle on one end of a piece of the vane stock ripped earlier.

The width angle will be 45 degrees, the bevel should be about 30 degrees, with both long points facing the same direction and opposite the direction of the bevel on the edge of the stock.

Place the stock so it fits within the vane frame to determine the overall length of this first vane. You can check the fit of the angles approximately at this time but until the opposite end is cut, it isn't possible to do exactly.

Mark the approximate length of the vane, and cut it an inch or so longer than needed to allow for angle adjustments when it is fit into position. Try the vane when it cut to see how well the angles fit.

Make scribed adjustments and check the angles on the saw so later cuts on the next vanes will all be the same. Mark the frame about 3 inches 7. If it is ten inches shorter, you can reduce the length of subsequent vanes by the same amount to space them equally without measuring each one. Cut all the vanes needed to complete the louver. Make sure each angle is cut so it faces the same way in relation to other angles and sort them by length. Begin installing the vanes working from the shortest top to the longest, nailing each end, and keeping the vanes flush with the bottom back of the face frame so insect screening can be stapled to them later.

Turn the louver over to complete nailing from the back side where the ends are more easily accessed. Use a finish nailer with corrosion resistant nails or corrosion resistant screws and a screw gun depending on your preference. Remember, the louver will be exposed to weather conditions, so it should be built securely to prevent wind damage that will result in leaks into your building.

Place the louver on the table with the back up, and stretch the aluminum insect screen on it. Make sure to staple through the screen into the louver vanes to help prevent them from bowing or loosening. Include your email address to get a message when this question is answered. Use suitable lumber for this exterior building project.

Western cedar privacy fence boards have an attractive rough sawn surface and are weather resistant and light weight making them a good choice, but treated pine can be used for the frame securing it to the gable for strength. Helpful 0 Not Helpful 0. A compound miter saw, table saw, and pneumatic nailer make the job easier.

Submit a Tip All tip submissions are carefully reviewed before being published. Secure parts with strong fasteners to prevent failure and a potential leak into your structure. Helpful 1 Not Helpful 0. Helpful 1 Not Helpful 1. Related wikiHows How to. How to. Co-authors: 8. Updated: January 29, Categories: Featured Articles Building Roofs.

Thanks to all authors for creating a page that has been read 58, times. Did this article help you?

|

Manual Saw To Cut Wood 800 Woodcrafters Supply Water |

Bad_GIRL

04.02.2021 at 17:14:13

Bro_Zloben

04.02.2021 at 21:57:39