Types Of Woodworking Planes Github,Best Plunge Router For Woodworking,8 Letter Big 4 Teams 3d,Best Rap Quotes About Success - PDF Review

Remember to adjust your planes blade position for the amount of material you want to remove, the wider the mouth opening the larger the material being removed will be. And the smaller the mouth the less material will be removed. Depending on the type of material your working on you will have to Types Of Hand Planes Woodworking 01 adjust the mouth size to get the perfect position.

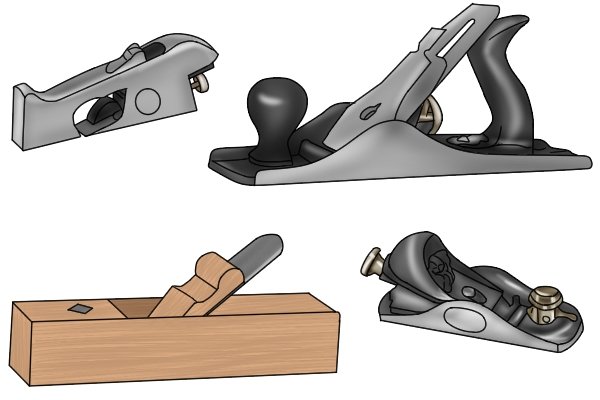

What Are the Different Parts of the Plane? I have added an image of the breakdown of a typical plane; while there are many different types of wood planes the design is similar. The lever cap is held in position using a screw and a locking cam.

You will see this working as the shavings come out as curly pieces of removed Types Of Hand Planes Woodworking Equipment wood. The blade has a big keyhole type slot cut into it which allows for the screws and depth adjustment control to go thru it. The blade is secured in place by the lever cap at a 45 degree and to the sole [ bottom plate ] with its beveled sharpened edge facing the work piece.

If the plane is not right on you can adjust the lateral angle of the blade using lateral adjustment control to the left or right as needed. It is used to set the distance between the blades cutting edge and the front portion of the mouth. Some types of wood planes have a ribbed sole that reduces the friction during planning. This feature is really handy when planning sappy types of wood.

While many woodworkers do there planning with thickness planers and power planes hand planes are still the go too tool for trimming and working on material that is too wide for their particular planer. The trick to getting the best result with your hand planning jobs is having a razor sharp blade and the edge is parallel to the material.

Holding your plane at a slight angle will increase the planes cutting angle while removing the material. To get a nice smooth finish [ smoothing ] plane parallel to the woods grain.

Using your plane at an angle plane the outside edges to the pencil mark creating chamfered edges. Next, plane the board down until you have removed the chamfers. You can also use this pencil marking technique to create an accurate chamfer too.

While there are many types of wood planes the tuning and planning is typically the same. Whatever type of plane you choose to get, I recommend you get a good quality sharpening stone set to keep your plane blades razor sharp. Reverse the cutting direction if you tear out the wood. A mouth you can control. Some block planes feature an adjustable mouth, allowing you to better control the depth and smoothness of the cut.

Or, more accurately, pare away thin shavings from the shoulders and cheeks of your tenons. Granted, a shoulder plane sometimes also called a rabbet or rebate plane serves a specialized purpose, but one can be invaluable if you work regularly with mortise-and-tenon joints.

This makes shoulder planes perfect for trimming tight-fitting tenons and rabbets. Some also trim dadoes and grooves if narrow enough to fit in the channel. Shoulder separation. Use a shoulder plane to shave away tenon thickness on each cheek until it fits snugly into its mortise. Recommended models Veritas no. Commonly designated with numbers from 1 to 8 and some fractional sizes in between , bench planes range in length from about 5" no.

The most versatile bench planes measure about 12" to 15" long and are referred to as jack planes. With this length you can flatten and smooth faces and edges of boards and glued-up panels. We recommend a no. But that extra size adds a couple of pounds, which can be a benefit because it increases momentum for powering through cuts, although it does require greater exertion at the beginning of a stroke. Choosing between these two really comes down to your preference and strength.

Add degrees for difficulty. By replacing the frog, as with these two no. Recommended models No. Veritas no. After marking and installing biscuit joints in several boards that I've glued up edge-to-edge, I Skip to main content. Start with a block plane Buy this one first.

Facebook Pinterest Twitter Text.

|

Free Woodworking Clock Projects Kit 2x4 Scrap Wood Projects 09 Best Woodworking Marking Tools |

S_H_U_V_E_L_A_N

28.03.2021 at 13:57:26

151

28.03.2021 at 18:22:39

Gold

28.03.2021 at 14:54:34

095

28.03.2021 at 12:19:18