Small Workshop Dust Collection Manual,Open Hardware Summit 2020 Date,Woodwork Toys To Make Kimchi - Step 2

The motor and impeller sit atop a cone-shaped canister, the cyclone, which is connected to a trash can below. Chips or other large debris enter the cyclone and swirl downward, avoiding the impeller. The longer the cyclonic chamber, the greater its effectiveness at slowing down and separating large particles. Air is filtered either by a pleated internal cartridge or by one or more felt bags hanging off to the side of the machine.

Internal-cartridge cyclones use the least amount of floor space. The upper bags or cartridge filters of all collectors must be shaken out occasionally to remove fine dust.

Debris entering a single-stage collector passes through the impeller, many of which are made of steel. Even a small bit of metal, such as a screw, can cause a spark when it hits a steel impeller. Dust-collector explosions are rare, but the potential is there.

Debris, metal or otherwise, not only makes a racket when it hits an impeller but also imparts stress on the bearing and will shorten its life. One way to reduce the risk of fire is to choose a single-stage collector with a plastic or aluminum impeller. Steel impellers are fine, however, if you avoid using the dust collector to sweep up miscellaneous debris off the floor or workbench.

I also used the 1-hp collector with a PVC duct system 4-in. At that distance, because of increased resistance, the air volume drops to under cfm, less than recommended for woodworking tools. In reality, however, one can live with that. When I hooked up the 1-hp collector to a newly installed metal duct system, with my tools in the same configuration as before, I was really surprised. The air volume was back up to cfm, very acceptable.

Then I hooked up my old 1-hp collector, which is outfitted with oversized felt bags available from Oneida Air Systems that improve airflow and capture fine dust , and I measured almost cfm.

Hooked up to a 6-ft. Cyclones and two-stage collectors have slightly more internal air resistance; hence the lower cfm reading. Performance ranged from good to so-so, depending on how much sawdust was being spit out by my tools. The best way to direct maximum airflow to the tool being used is to attach a blast gate to each hose.

Hooked up to a PVC duct system a run of about 25 ft. A two-stage unit such as the Oneida costs almost twice as much. Penn State Industries also sells a cyclone collector. With two blast gates open, the air volume dropped and was insufficient to operate two big machines at once. More horsepower does mean more noise; both registered 85 decibels at 8 ft. The Delta comes wired for volts but can be switched over to volts. The Oneida comes without cable or switch.

It can be wired to run on either current. A 2-hp unit can sometimes handle two machines at once Hooked up to two 6-ft. When I connected the 2-hp units to the PVC duct system, they too were robbed of considerable power, but one machine could be operated at a time with satisfactory results.

When connected to a metal duct system, the Jet collector really moved a lot of air, cfm at the tablesaw-jointer connection after about 25 ft.

With two blast gates open, the air volume was reduced to less than cfm, still acceptable for some operations. The Dust Boy produced slightly lower readings but still had more than enough power to run one tool at a time in any configuration.

If you regularly operate more than one machine simultaneously, it would be wise to look at 3-hp or bigger dust collectors. They cost more, however. Most 2-hp collectors come wired for volts. The Dust Boy can be run at either volts or volts. On the matter of choosing a dust collector, a two-stage cyclone gets my top vote. A small cyclone collector takes up less room, is easy to empty and runs very clean.

For example, on all of the single-stage units, even after running them for only an hour, fine dust appeared on the machine and in the area around it.

The Oneida cyclone, outfitted with an internal filter, rubber gaskets and wide metal ring clamps, seals better. Two-stage units such as the Dust Boy Delta also makes a two-stage collector are also nice and compact. The Dust Boy takes up 6 sq. The Dust Boy as does the Oneida Small Workshop Dust Collection Game comes with a Leeson motor and cast-aluminum housing and impeller fan , and the sturdy plastic barrel holds a lot of debris, 55 gal.

Before it can be emptied, however, the heavy motor and housing must be lifted off. Removing the lower bag of a single-stage collector is an easy matter of loosening a band clamp. The real fun begins when you try to reattach it. The lower bag must be wrapped around the metal waist of the machine and held in place before the clamp can be cinched.

Some manufacturers, such as Jet, add an elastic band inside the lower bag to facilitate reattachment somewhat. The skirt and a standard gal. I just wish the skirt were made of felt rather than the more porous woven fabric. This setup will reduce the air volume. When an ad says a collector is rated at 1, cfm, what does it mean? Not much, really. Cfm stands for cubic feet per minute, a measure of the volume of air moving past a point of reference.

The cfm figure needs to be put in the context of the amount of resistance, or friction, present called static pressure, or SP. Air moving through duct or hose encounters resistance, just as a person would slipping down a water slide. The more bends and bumps, the slower the ride or the lower the air velocity and volume.

Many manufacturers rate their machines without bags or duct attached. While trying out a number of dust collectors, I measured their performances under real working conditions, using flexible hose, PVC pipe or metal duct in my sq. I also measured collectors hooked up to a straight piece of 6-in.

Collectors ranging in size from 1 hp to 2 hp have impellers fans sized from 10 in. All things being equal motor speed and impeller design , a bigger impeller coupled with a bigger motor will move more air than a smaller pairing.

There are some differences among collectors; to learn more, ask a manufacturer for an impeller performance chart. As soon as any collector is hooked up in the shop, performance declines in relation to the length and type of hookup.

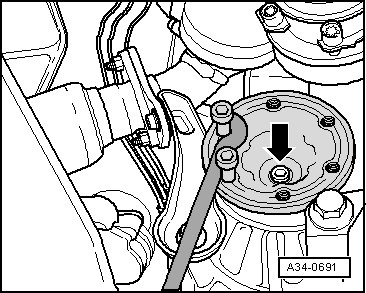

Materials that affect airflow. The metal elbow top , which is designed for central dust-collection systems, has a gentle sweep, which lowers resistance to airflow. Plastic PVC pipe has a tighter-radius bend and restricts airflow more. Dust collection in a small or home shop is very often an afterthought. Though I cannot stress enough how important a dust collector is — especially for woodworkers.

Most stationary woodworking tools table saws, drum sanders, etc. This is also true for hand tools, like belt sanders. You may have tried connecting a regular vacuum cleaner or even a shop vacuum to these machines if the dust port is the correct size.

Can be operated as either a stationary, central dust collector or a mobile unit. This review is going to concentrate on some of the best dust collectors for the small professional or home shop. Some tools require high-power suction to get rid of the dust effectively. So you need to look at this carefully. Spending too much on a dust collector that way exceeds your needs is going to be a waste of money. Another thing you may want to consider is the capacity of the bag.

Air filtration can also be important. The size of the particle filtration is measured in microns, really good filtration systems will remove particles as small as 1-micron. One of the specs that most people find difficult to interpret when we talk about dust collection systems or any system that uses pressurized gas or fluids is the term static pressure. Not all dust collection systems will give static pressure specs, because there are many factors that can affect this, such as the pipe or ducting size diameter as well as length , filter types or any other factor that inhibits the airflow.

Though when these specs are provided, it can be helpful in determining the efficiency of the machine. Static Pressure SP is expressed in inches water gauge and this spec will be given simply in inches.

It may seem strange to measure pressure in inches. As you blow harder the ball will rise according to the amount of pressure inside the tube.

If you release some the air from the tube, the pressure will drop, causing the ball to fall. If we measure the distance that the ball falls, this tells us how much the pressure has dropped. Ideally, you want the SP of your dust collection system to be as low as possible. Basically, a high SP rating means that there is a greater loss of pressure in the system.

So you need to make sure that you have a circuit that can provide the correct volts and amps for the machine. Their prices range from really cheap to not so cheap — depending on their power and specs. The bigger models will usually have larger bags to hold more dust. Will handle just about any hungry woodworking machine.

Affordability is one factor that could easily make the Shop Fox W top of your wish list. Another attraction for the small shop is the compact size of this dust collector. This can be a slight problem for garage shops or other multi-use work areas. For most tools with a dust port, the suction provided by the Shop Fox W should be fine. Some tools require a suction of up to CFM to remove the dust that they produce.

Something to consider when looking at this dust collector. The bag is really convenient to use, it has a zipper at the bottom for easy emptying and a view window so that you can check how full it is at a glance. It also has a foam covered handle, making it very easy to lift when mounting. The large paddle on-off switch is easy to locate for hassle-free operation. At the same time, it provides you with excellent suction and a reasonably large dust collection bag.

|

Do It Yourself Wood Plank Wall Quotes Carpenter Tool Storage Rate |

morello

24.02.2021 at 16:17:13

Odet_Ploxo

24.02.2021 at 23:22:34

AmirTeymur

24.02.2021 at 12:50:39

Sex_manyak

24.02.2021 at 10:19:55