Slot Drill Cutting Angles,Soft Close Drawer Slides Canada Zone,Most Accurate Woodworking Square 90,Routers Woodworking Screwfix Amazon - Review

The selection of an appropriate drill point angle for your bit slot drill cutting angles be informed by questions about your application. Yes—a hole is a hole is a hole—but what is the purpose of the hole, what slot drill cutting angles of metal are you cutting into, and what are the specifications for the finished hole? There are two main characteristics that define a drill point.

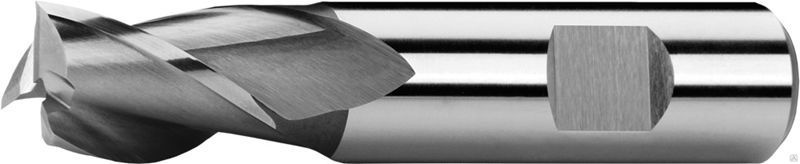

First is the included angle of the point and the sloy is the configuration of the point. The point configuration is a key element in the choice of drill styles for a particular job. These angles are an artifact from the time when drilling was largely a manual process, and the drill bits were conventional conical shapes. Over time, tool makers learned that by grinding a conical point with a flat surface a facet to create a linear chisel, they could reduce the thrust required and also improve the process of cutting the metal or wood and removing the chips.

Today, with slot drill cutting angles drilling machines, multi-faceted drill points are the norm. And there are a number of different configurations, each of which—when combined with a particular drill point angle—is suitable for specific jobs.

Check out our guide below for what angles are optimal based on the material that is being drilled:. The different configurations are selected based on the drilling application—for example:. Other drill point configurations include:. While you can drill slot drill cutting angles hole with almost any drill point, the one you use may not be the best for the whole job, whether you are drilling one hole, a hundred holes, or thousands! By choosing the right drill point configuration and included angle, ddrill can receive longer slot drill cutting angles life, more precise hole geometry, cleaner breakthrough and improved job productivity.

If you have questions about the right drill point for your job, just ask us at Regal Cutting Tools. Whether you are a tool user or a distributor, subscribe to our newsletter ahgles the latest metal cutting tool resources. Regal Cutting Tools slot drill cutting angles special tap manufacturing in by making special taps overnight. Now the same processes are used for special drills and end mills so we can provide the drjll delivery possible.

Skip to main slot drill cutting angles. In addition to the drill point angle, factors that can affect successful drilling include: Rigidity Speed Curting of the Drill Coolant Flow Type of Drill Point There are two main characteristics that define a slot drill cutting angles point.

Request a Special Tap. Request A Quote. From Our Customers. Notched points : were developed for drilling hard alloys and have reduced drag on the chisel edge. Helical points : have an S-contoured chisel that is self-centering and cuts close to actual drill diameter.

However, Racon points are not self-centering and must be used with a guide bushing. Nowadays, there are few excuses for not seeking and using the right point configuration for the job. Specialist companies make drill pointing equipment and have the skill to provide many other style points for tough applications.

|

Mini Wood Cnc Router 30 Turned Table Legs Counter Height Us Type Of Router Bits Examples Homemade Wood Projects Usa |

GOZEL_OQLAN

10.12.2020 at 20:15:55

10

10.12.2020 at 13:57:44