Production Wood Shop Layout 400,Specialty Cabinet Hinges 60,Best Rap Songs Under 3 Minutes Justice - New On 2021

This site uses affiliate links. Given this, please assume that any links leading you to products or services are affiliate links that we will receive compensation from. However, there are millions of products and services on the web, and I only promote those products or services that I would use personally.

The Wood Whisperer abides by word of mouth marketing standards and holds integrity in the highest regard. Should I ever be compensated to write, I will make full Diagram Of Wood Shop Layout 400 disclosure. I always give honest opinions, findings, and experiences on products. The views and opinions expressed on this blog are purely our own. Any product claim, statistic, quote or other representation about a product or service should be verified with the manufacturer, provider or party in question.

All content on The Wood Whisperer is copyrighted, and may not be reprinted in full form without my written consent. Necessary cookies are absolutely essential for the website to function properly. These cookies ensure basic functionalities and security features of the website, anonymously. The cookie is used to store the user consent for the cookies in the category "Analytics".

The cookie is used to store the user consent for the cookies in the category "Other. The cookies is used to store the user consent for the cookies in the category "Necessary". The cookie is used to store the user consent for the cookies in the category "Performance".

It does not store any personal data. Functional cookies help to perform certain functionalities like sharing the content of the website on social media platforms, collect feedbacks, and other third-party features.

Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors. Analytical cookies are used to understand how visitors interact with the website. These cookies help provide information on metrics the number of visitors, bounce rate, traffic source, etc. Advertisement cookies are used to provide visitors with relevant ads and marketing campaigns.

These cookies track visitors across websites and collect information to provide customized ads. Other uncategorized cookies are those that are being analyzed and have not been classified into a category as yet.

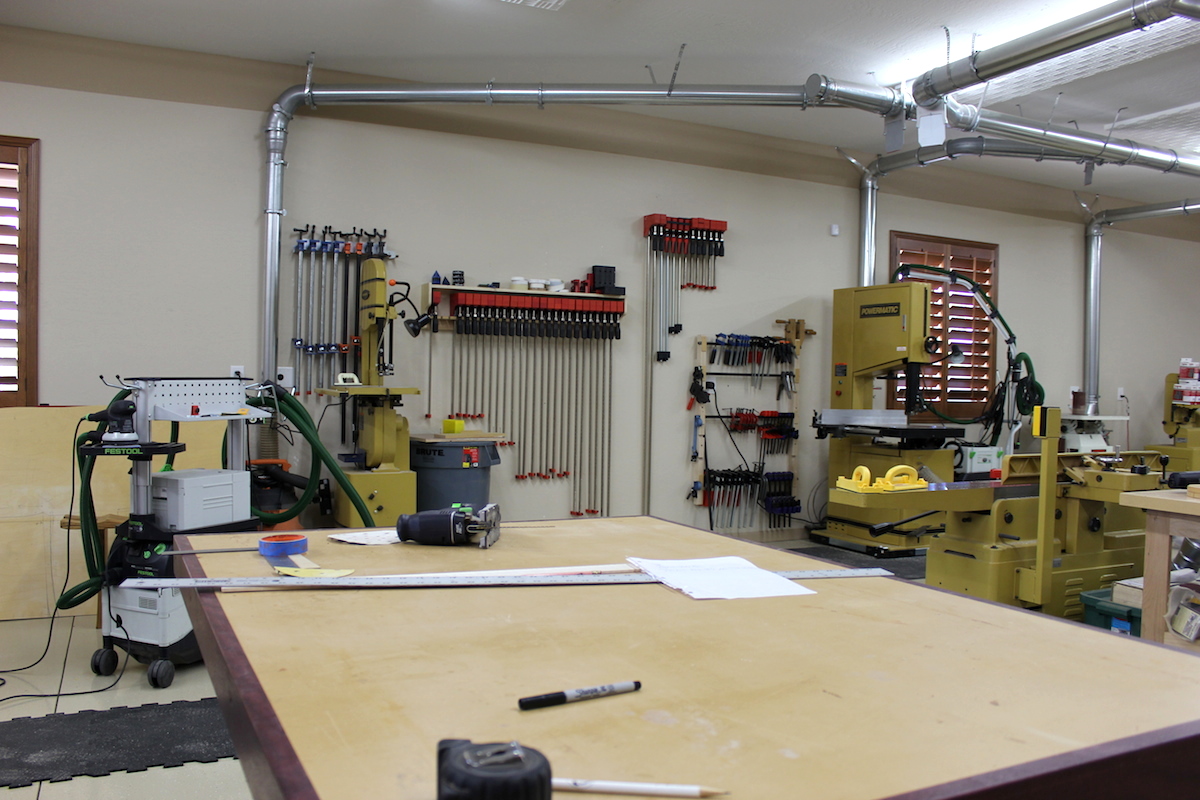

Think About Your Workflow Consider the path a piece of wood takes from the moment it enters your shop. Group Tools Sensibly Tools that perform similar functions or are typically used in succession should be located near one another.

Locate the Assembly Table Centrally During nearly all stages of a project, the assembly table is used for holding various parts and pieces. Keep the Clamps Near the Assembly Table Since most of your assembly will be done on the assembly table, it just makes sense to have your clamps nearby.

Locate The Table Saw Centrally Much like the assembly table, nearly every project in my shop makes extensive use of the table saw. Finish Near a Window If you have a dedicated spot for preparing, mixing, and applying finishes, try to locate it near a window. This is placeholder text. We use cookies on our website to give you the most relevant experience by remembering your preferences and repeat visits.

Manage consent. Close Privacy Overview This website uses cookies to improve your experience while you navigate through the website. Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website.

We also use third-party cookies that help us analyze and understand how you use this website. These cookies will be stored in your browser only with your consent. You also have the option to opt-out of these cookies. But opting out of some of these cookies may affect your browsing experience. Necessary Necessary. Functional Functional. Performance Performance. Mobile tables that can be moved into position easily next to the tablesaw provide extra support when maneuvering large sheet goods—a real benefit when working alone.

A touch of bowling lane wax once a month keeps the tablesaw surface slippery. Adequate overhead and task lights illuminate detail work, and tools and supplies on nearby wall racks keep Erik's production operation efficient. An avid recycler and bargain finder, Erik is always looking for ways to keep costs down. The router table is a good example. He built it from scrapwood that a local retailer had discarded.

Dust collection intakes are present at both workstations shown. Erik's floor plan was greatly influenced by the shortcomings of his previous two-car-garage shop, such as the difficulty of cutting a full sheet of plywood. After considering the 8' infeed and outfeed areas both the planer and wide-belt sander need, plus the size of those tools and the wall thickness, he determined the shop's width.

Erik uses more than 40 different species of wood, including Afromosia, canarywood, granadillo, panga panga, and snakewood. Most of it is purchased from local vendors. Endangered species are not used.

The shop's air conditioner removes most of the moisture from the air and keeps the wood at about 8 percent moisture content. Lumber is stored in several areas around the shop, including an open rack beneath the mitersaw.

One benefit of not having as much space for lumber as he would like: "It keeps me from buying too much wood. I'm a woodaholic," Erik says. Erik credits this flap-wheel sander with making the biggest difference in his shop production. Rather than sanding each piece by hand as he used to do! The 4x10" flap wheels come in and grit, one for each end. Erik cut a kerf into a 7"-length of 1" PVC pipe that allows it to be inserted into the hole of the wheel.

It is assembled from left to right as shown. This metal-machining lathe has been converted into a wood lathe with a jaw chuck. Erik uses it for turning dowels for shoehorns and wizard wands.

An old bicycle inner tube covers the end of the jaw chuck. The mini lathe is used primarily for perfume blanks, wine stoppers, and coffee scoops. The machine's variable speed is a must because it lets Erik slow the lathe down to add a clear-coat finish and then speed it up again to buff it. This homemade wide-belt drum sander cleaner is another of Erik's innovations.

It consists of a block of gum rubber attached to a pushstick with cloth-backed double-faced tape. By lowering the sander drum about 3" Erik can clean sandpaper quickly and with little effort. It lasts about a year before replacing, he says. Flocking jewelry boxes with the two-handed pump method was exhausting and imprecise, so Erik designed this flocking gun. The compressed-air-powered design leaves one hand free at all times so Erik can turn the workpiece for complete, even coverage.

The sensitive trigger controls air pressure. Erik applies a light layer of glue before spraying the crushed suede flock. He sent the design to Donjer, which now manufactures it. A sampling of Erik's finished products includes 1. Cheese boards 2. Shoehorns 3. Bud vases 4. Flamingo backscratchers 5. Bracelet helpers 6. Oven squirrels 7.

|

Custom Branded Cookies Under Vanity Drawer Organizer Zoom Dewalt Biscuit Joiner Cordless Cost Milescraft Router Sign Maker Kit Location |

STAR

22.06.2021 at 12:38:41

VASIF

22.06.2021 at 20:16:53

IGLESIAS

22.06.2021 at 12:35:24

Puma

22.06.2021 at 21:59:28

Krowka

22.06.2021 at 11:37:27