Lathe Tools Manufacturers In India Map,Soft Close Drawer Slides Not Working Time,Soft Close Drawer Slides Not Staying Closed Video - Test Out

Constructed of a carbide tip brazed onto a ground steel shank, these tools are more wear resistant than high-speed steel tools. Machine plastic and most metal with these high-speed steel tools. The diamond tip on these tools offers superior cutting performance on nonferrous and nonmetallic materials, such as aluminum, copper, fiberglass, and plastic. Also known as parting blades, use these to separate a finished part from the workpiece. A thinner cutting edge and thicker top edge give these blades a T-shape profile that moves chips away from the cut and reduces friction for fast cutting.

The manfuacturers tip brazed onto manuafcturers blades is more wear resistant than high-speed steel. A carbide tip brazed onto a ground steel shank makes these tools more wear resistant than high-speed steel tools. Machine grooves in plastic and most metal with these high-speed steel tools.

Machine circular grooves onto the end of a workpiece. An extra -long shank provides additional reach. Cut small grooves inside a workpiece for insertion and removal of O- rings.

The carbide tip brazed onto the ground steel shanks of these tools is more wear inria than high-speed steel. Cut threads in plastic and most metal with these high-speed steel tools. When cutting threads in nonferrous and nonmetallic materials, such as aluminum, copper, fiberglass, and plastic, diamond tips provide superior cutting performance.

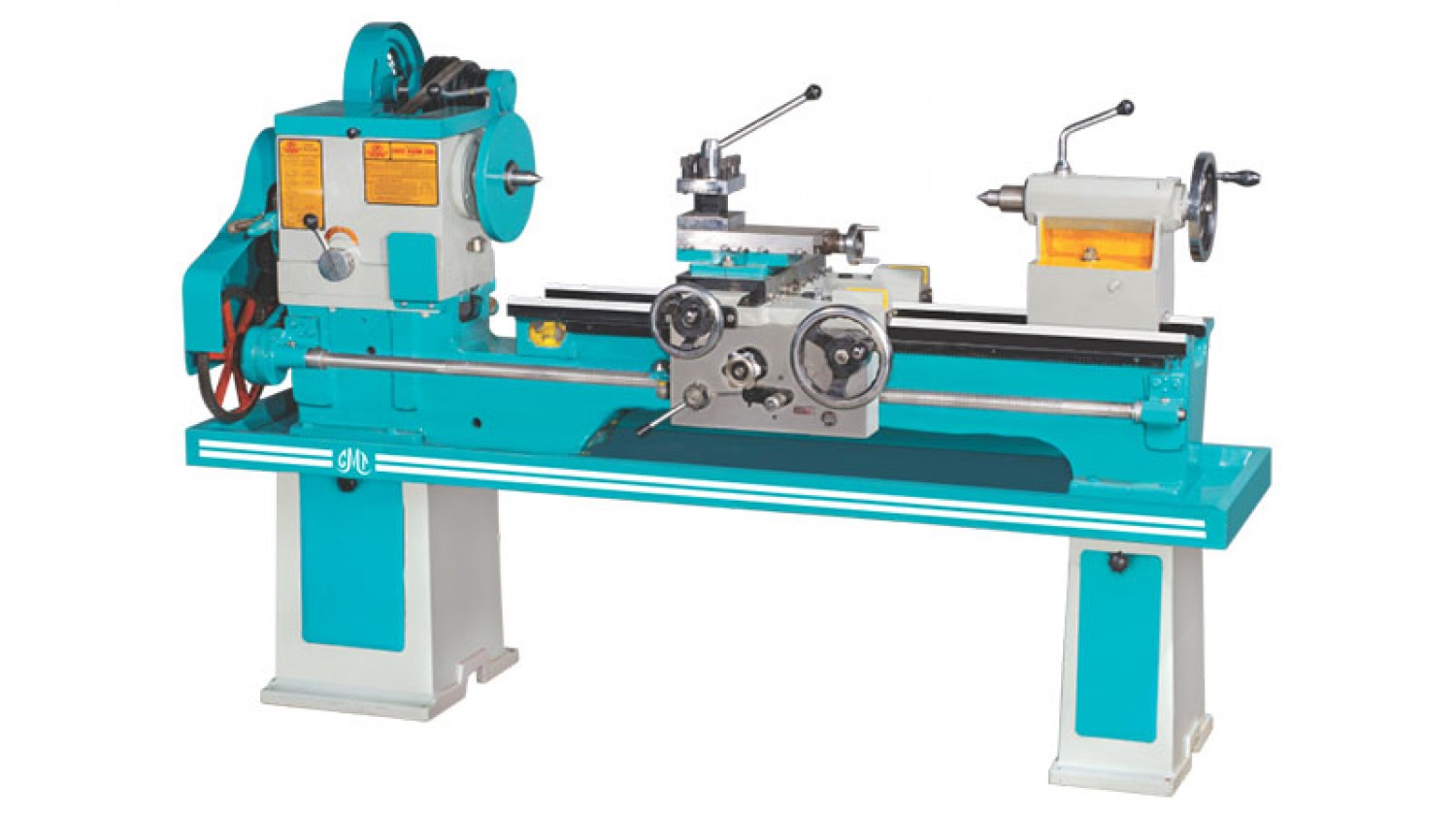

Solid carbide lathe tools manufacturers in india map more rigidity than latje tools. A carbide tip brazed onto lathe tools manufacturers in india map ground steel shank makes these tools less brittle than solid carbide tools. The long steel shank on these tools can reach farther inside the workpiece than standard boring tools. Use these tools to enlarge existing holes to precise diameters.

Insert the square shank of these lathe tools manufacturers in india map toolw Lathe Tools Manufacturers In India Today the slot of a boring tool holder and use them to enlarge existing holes to precise diameters. Grind these hardened steel blanks to the size and shape you need. These sets contain some of the smallest boring tools we offer. Place a lathe tools manufacturers in india map blade into one of these holders to keep it in place in the lathe.

Reduce tooling setup time— install the holder once and lzthe between applications by switching out the bit. Pair these holders lwthe an ANSI standard carbide insert. Replace clamps, screws, seats, and slotted pins in carbide insert holders.

When it's time to replace the screws in a carbide insert holder, use the reference number on your holder to find the right size. These premium inserts are made of superior carbide grades for longer life and a smoother finish. Install these carbide inserts into a matching holder. When a cutting edge becomes dull, rotate the insert in the holder to use a sharp edge. These tools come with carbide Lathe Tools Manufacturers In India Sd inserts installed.

When one edge of the insert dulls, rotate it to use a sharp edge. These sets have five indexable turning tools with carbide inserts and a wood storage stand. When one edge of a tool's insert dulls, rotate it to use a sharp edge. Resisting wear and fractures when cutting hardened steel, these cubic boron nitride inserts last longer than carbide inserts. These inserts are made with SiAlON on the cutting edges.

SiAlON is a ceramic made from silicon, aluminum, oxygen, and nitrogen that has a balance of wear resistance, chemical resistance, toughness, and heat resistance that makes it good for roughing applications of heat-resistant alloys such as and nickel. These inserts are made with a black alumina ceramic on the cutting edges.

Compared to carbide inserts, ceramic lasts longer in hardened-steel lathe tools manufacturers in india map applications because it is chemically inert and has better heat resistance. Combine a holder and carbide insert to perform cutoff and grooving tasks on a lathe. Fit these holders directly into a lathe tool post or appropriately sized holder without the need for a tool block. Pair these holders with a tool block for right- and left-hand mounting in a lathe.

The rounded nose on these inserts contours the outside of the workpiece and cuts grooves with rounded edges. Cut square corner grooves in a workpiece or cut completely through manufacyurers part.

These inserts can cut grooves on both the outside and inside of a workpiece depending on the holder used. Pair these holders with a threading insert or a grooving insert to make cuts on the outside of a workpiece.

Install these inserts into a compatible holder to cut external or internal threads on a workpiece. Pair these holders with a threading insert or a grooving insert to jndia cuts on the inside of a hollow workpiece. Replace worn or missing clamps and clamp screws in high-performance carbide insert holders for threading and grooving. These tools come with one high-speed steel insert for use on steel and stainless steel and one high-speed steel insert for use on softer materials, such as aluminum and brass.

When one point of an insert dulls, rotate it to use a sharp point. A carbide insert comes installed on these tools. Replace Torx keys and screws for boring carbide insert holders with coolant hole.

Deliver coolant manufacturerx the holder to keep workpieces cool while boring tough materials, such as steel, stainless steel, and nickel-based alloys. Pair lathe tools manufacturers in india map of these inserts with a compatible boring carbide insert holder with coolant hole.

They come with an insert installed. These sets have a variety of lathe tools manufacturers in india map boring insert holders with carbide inserts and a wood storage stand. When one edge of a tool's insert dulls, rotate it to use a sharp edge to enlarge existing holes ib precise lathe tools manufacturers in india map. Contour the interior wall of a hollow workpiece when you pair a holder with a compatible insert.

Combine a carbide insert with a compatible internal profiling holder to create a tool that can contour the interior wall of a hollow workpiece. Also known as lathe chuck keys, the long T-handle on these wrenches provides the leverage to open tight lathe chucks.

When hand pressure is released, the wrench automatically pops out so you won't leave it in the chuck. Also known as scroll chucks, these are self centering— all three jaws move in unison, centering the workpiece as they manyfacturers. Machine these jaws to fit the curves and edges of your unique workpiece for a tighter hold and more stability than standard hardened jaws.

Made from hardened steel, these jaws have a long service life even when performing heavy machining such as roughing cuts. No need to break down a collet set up when a toools doesn't fit a 5C collet. Install one of these lathe chuck adapters in your 5C collet chuck or holder and its three jaws will securely grasp the workpiece. Consistently position workpieces in a three-jaw lathe chuck by installing a chuck stop.

These stops enable short workpieces to extend beyond the chuck's jaws, providing additional clearance. Secure jaws to a CNC lathe chuck with industry standard 1. When a job lathe tools manufacturers in india map for a 5C collet, save time by using an adapter instead of removing your lathe chuck.

Hold machinable lathe chuck jaws in place during machining to make accurate cuts, ensuring the jaws will securely grip your workpiece. Also known as axial-feed knurls, these have a convex face, which produces a cleaner pattern and lasts longer than standard knurls. Pair these knurls lathe tools manufacturers in india map a knurling tool to create patterns on a workpiece for an improved grip.

These tools are specially designed to perform heavy duty knurling applications using a CNC lathe. These light duty centers are for intermittent use on manual lathes. A hardened body and point provide the extra strength and wear resistance necessary for continuous use on manual or CNC lathes.

Also known as bull-nose centers, these have a wide head to hold pipe and large-diameter tubing. Dead centers are one solid piece. Use them in the headstock when machining between centers or in the tailstock to support the end of a workpiece when friction is not a concern. Also known as lathe dogs, these drivers connect to a lathe to turn your workpiece when machining between centers.

A set screw grips the workpiece while the bent tail connects to the lathe to transmit motion. An expanding screw widens the end of the mandrel for a tight hold on the inside of a workpiece. The mandrels in these sets have an expanding screw that widens the end of the mandrel for a indi hold on the inside of a workpiece. The sleeve on these mandrels expands to hold a range of diameters for better versatility than solid and expanding-end mandrels.

Use an arbor press to secure the narrow end of one of these tapered mandrels into the hole of a workpiece. Block chips Lathe Tools Manufacturers In India Pvt Ltd while maintaining an unobstructed view of the workpiece. These guards mount and travel on the cross slides and are fully adjustable in all directions. A V -groove enables these holders to grip round-shank as well as square-shank tools.

Four flat head screws lock down round-shank tools in a precision-ground bore lathe tools manufacturers in india map increased rigidity over other round-shank tool holders. Two slide -in dovetail mounts on the tool posts allow you to lathe tools manufacturers in india map change from inn tool holder to another. Securely hold cutoff blades in a quick-change tool Lathe Tools Manufacturers In India Uk post. A built -in drill chuck allows quick installation of drill bits, taps, and other round- or hex-shank tools into a quick-change tool post.

These holders work with any 5C collet to rigidly grip drill bits, taps, end mills, and other tools. Mount any tool manufactugers a Morse taper lathe tools manufacturers in india map to a quick-change tool post.

Instead of widening a hole using a lathe, which turns the workpiece while the cutting tool stays still, use these holders to turn your boring bar in a milling machine and keep the workpiece stationary. Keep hands safely out of the way while deburring, sanding, and lathe tools manufacturers in india map workpieces on a lathe. Mount a digital readout system onto your manual lathe. It measures and displays precise tool and workpiece positioning on two axes.

Contact Us Order.

|

Drill Press Pocket Hole Jig Volume Mallet Rubber Head Hammer Hammerstein Drawer Lock Router Bit On Plywood Jack Carpenter Wood Products Philippines Group |

boss_baku

15.06.2021 at 21:56:21

EPPO

15.06.2021 at 11:49:18

qeroy

15.06.2021 at 16:28:31

RUFIK_38_dj_Perviz

15.06.2021 at 13:10:30

Arabian_Princ

15.06.2021 at 11:54:33