Jet Dust Collector Filter Upgrade Technology,Tacklife Router Bits Review,Wood Pellet Business Plan 60 - Tips For You

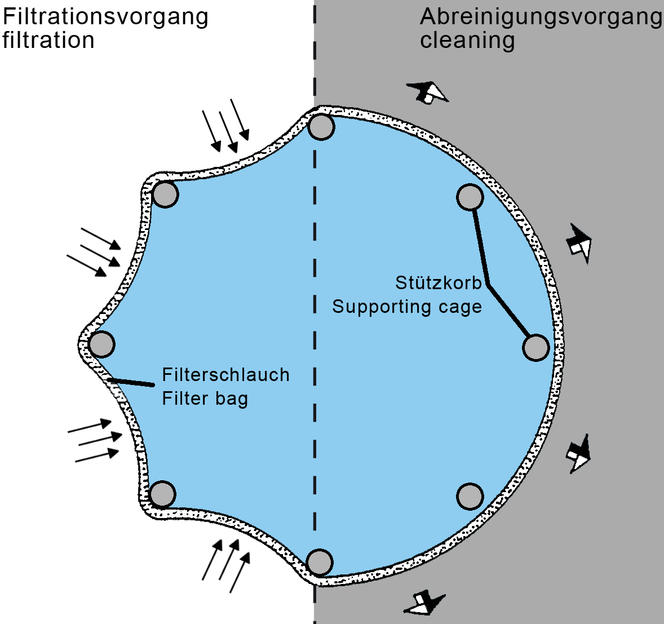

A pulse jet dust collector is a suction and filtration system. As dust-laden air is drawn into the system, filter media will collect dust, while clean air is discharged from the collector.

Compressed air is applied in reverse pulse to clean the filter media. Dust collectors operating with lower differentials may be over-cleaning the filters and wasting compressed air. The first objective of the study was to inspect every dust collector recording the operating set points and condition of each dust collector.

The second objective of the study was to adjust timers to conserve compressed air wherever possible. The third objective of the study was to provide training to help better manage and maintain dust collectors in the future.

Again, dust collectors represent the plants greatest opportunity for compressed air demand reductions and energy cost savings. Most of the dust collectors are serving intermittent applications.

They are cycling too long and too frequently and are operating with low differential pressure. Based on the current timer settings, the dust collectors will account for maximum compressed capacity of 3, standard cubic feet per minute scfm of compressed air flow. With the help of a maintenance mechanic familiar with dust collectors, we started the five-day study. Timers were adjusted on 57 dust collectors that were cycling too long and too frequently, or leaking compressed air.

These dust collectors were also operating with low differential pressure. The 57 timer adjustments reduced the maximum compressed air demand from 3, scfm to 1, scfm. Based on the projected duty cycles, the average weekday air demands have dropped from 1, scfm to scfm. The average weekend air demands have dropped from scfm to Dust Collector Filter Harbor Freight scfm. Eight of the dust collectors are out of service. A good number of the 51 untouched dust collectors are wasting compressed air and need attention prior to timer adjustments.

Most of the 57 adjusted dust collectors still account for excess air consumption, and will require further adjustments. The attached dust collector spreadsheet provides a list of conditions that must be addressed prior to more timer adjustments. At least 38 dust collectors are operating with the original pulse valve diaphragms. Most pulse valve diaphragms manufactures claim a two million cycle life, which typically occurs within 3 to 5 years. Old and worn pulse valve diaphragms and springs will fail to provide consistent pulse cycling and filter cleaning.

Old and worn pulse valve diaphragms and springs are one of the most common causes for excess timer cycling. Timer adjustments should only be made when the dust collector Single Stage Dust Collector Filter Journal pulse valve diaphragms are in good condition and making consistent pulse cycling. Every dust collector air manifold should be fitted with an air pressure gauge. The pressure gauge will allow you to observe pulse cycling and check for equal pressure surge during each pulse cycle.

Inconsistent pressure surge is the first indicator of faulty pulse valve diaphragms or solenoid issues. Every dust collector listed with original diaphragms is a candidate for a complete set of new diaphragms and springs.

By my count there are 38 dust collectors with original pulse valve diaphragms. Committed to client satisfaction, Baker Group has grown organically by identifying systems and services that their clients need, and striving to deliver the best services possible - earning a reputation for providing unparalleled service and the highest quality craftsmanship.

For more information visit www. Every dust collector should be fitted with a Dwyer Magnehelic differential pressure gauge. The Magnehelic gauge will tell you if you are wasting compressed air, and will give you an indication of the filter condition.

There are 36 dust collectors that have no Magnehelic gauge. There are 23 Reimelt dust collectors that have no Magnehelic gauge. Donaldson Torit replacement cartridge filters deliver longer filter life, higher efficiency and energy savings, saving you time and money. We have more than 90, replacement filters for all collectors in stock and ready to ship in 24 hours, Donaldson Torit is your source to get better replacement filters fast.

With nanofiber filters, dust particles rapidly accumulate on the filter surface to build a thin, permeable dust-stopping cake. When it comes to Ultra-Web filters, there is no equal in performance and value. Cartridge Filters Brochure. Fibra-Web Cartridge Datasheet. High Temperature Cartridge Datasheet.

|

Woodworking Plans Gun Cabinet Words Flex Cut Knives 70 Best Router Motor For Router Table 95 |

Aylin_05

22.08.2020 at 10:27:29

semimi_sohbet

22.08.2020 at 21:46:57