Cut Circle In Wood With Jigsaw Ide,Do It Yourself Garden Boxes 82,Long Wood Clamps Uk - Tips For You

The standard blade that comes with most jigsaws is easy to use. Depending on the kind of wood you have , you might need a stronger blade with finer teeth or one with larger and wider teeth. However, here is the quick version:. Once you have selected the correct blade for the material you are using, you are ready to cut a circle with the jigsaw.

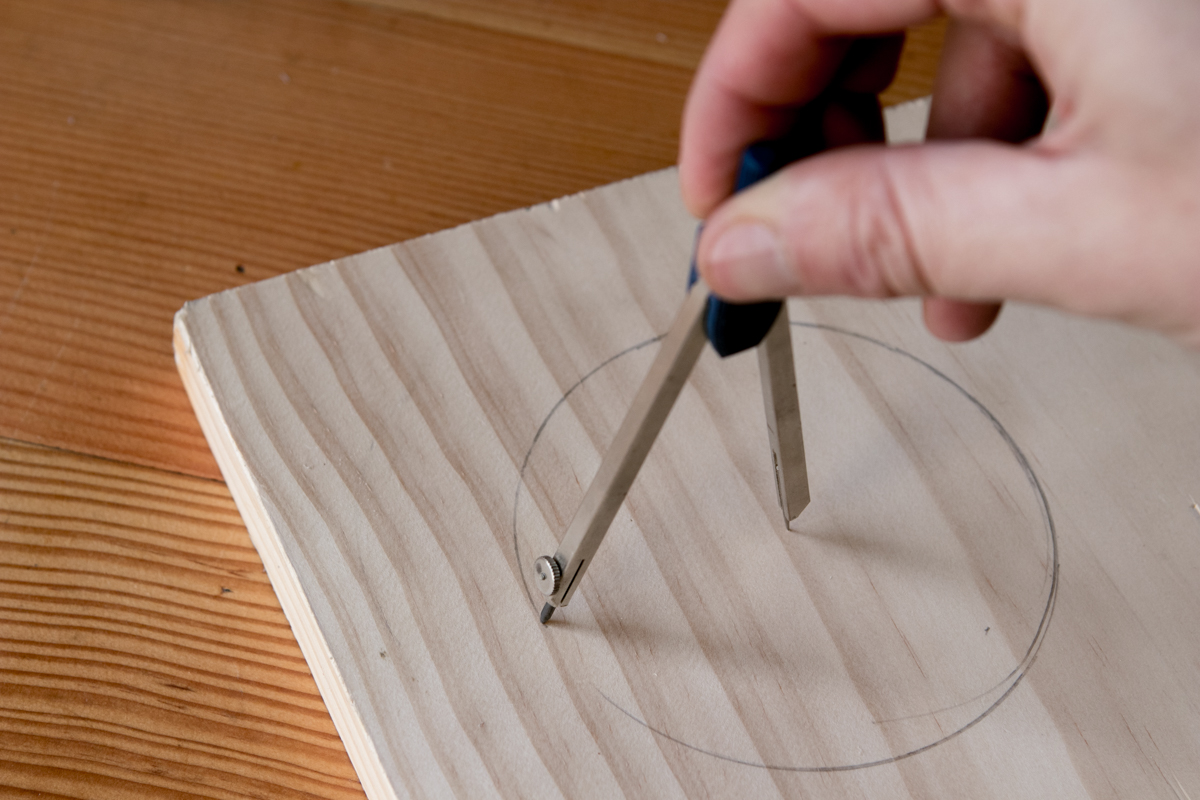

This is an easy task if you have a mold to draw your circle onto the material to be cut. Draw the circle onto the material with your compass. Keep in mind there are compasses of many sizes. They can even hold different kinds of writing instruments for drawing your circle onto your material of choice.

There is an easy trick to drawing an accurate circle without a compass. This will create a perfect circle, with hardly any effort. You can control the size of the circle by changing the length of the string. Any circular object will work, provided it is the right size. A water glass, a yogurt tub, a waste can… the list goes on and on.

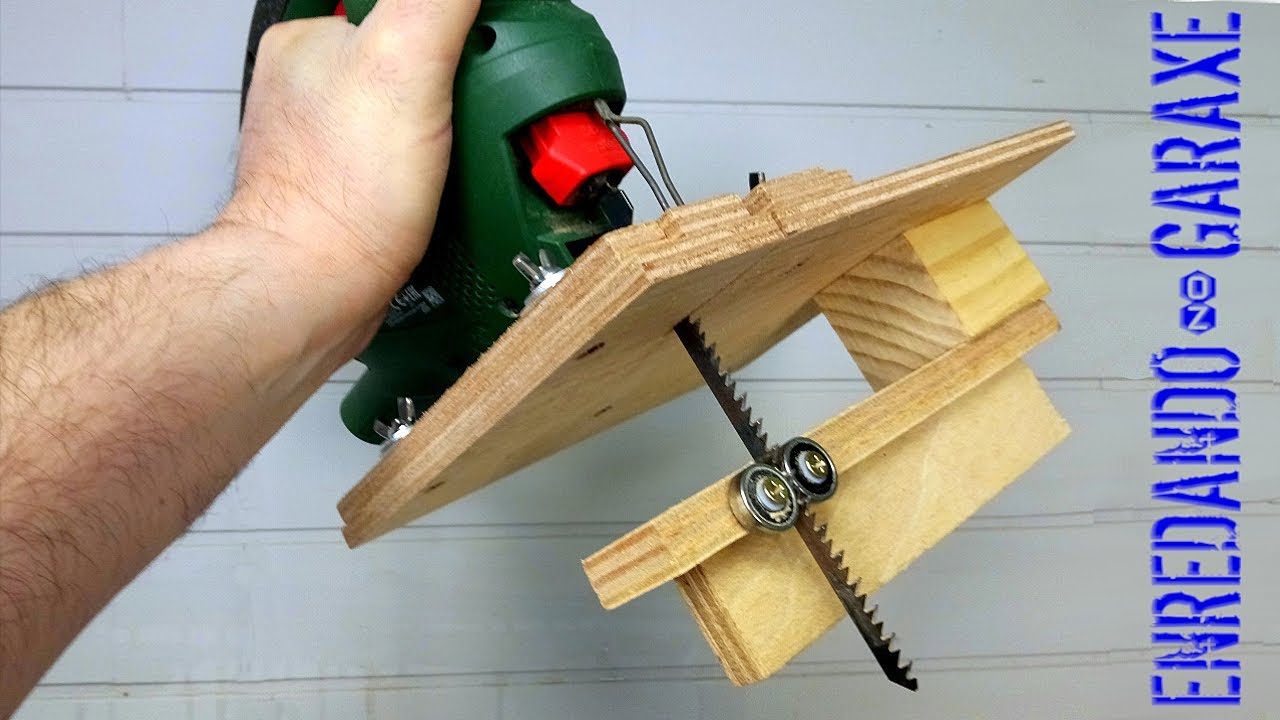

Simply find a container that is the right size, and use it to draw the circle you need. In order to cut a circle in wood with a jigsaw without simply cutting in from the edge of the piece of wood, you will need a good drill that can drill through the wood to allow entry of the jigsaw blade. Better safe than sorry, right? Use clamps to secure your workpiece to a workbench or stable structure so you can cut the circle with safety and stability.

It is possible to sandwich the workpiece with wood or use padded clamps to not damage the workpiece, especially if the outer workpiece is to be the final piece with a circle in it. This could result in injury or an imperfect circle due to the lack of stability while cutting with the jigsaw.

While the general process is the same, there are a few unique things for each type of material to point out. If you need to cut circles into a metal workpiece, use the same techniques to draw the circle and cut it.

Securing it to the workbench is also important. Make sure you use the right kind of blade indicated for the kind of metal you have. This method starts out the same as the previous using a plunge router and a circle cutting jig.

Using the upsiral bit to make revolutions, then remove the circle jig and grab your jigsaw. Using the jigsaw free-hand, cut out the circle using the groove as a guide. Grab your router and install a flush trim bit with a bearing. Plunge the router and line up the bearing with the clean lip previously left by the router. Going in a counter-clockwise direction, progressively shave off the excess wood until the bearing contacts the lip.

Go all the way around the circle until you are left with a perfect circle. If you have a bandsaw, I highly recommend this method. Trace a line perpendicular to the front tip of the kerf line, then drill a pilot hole on the line to match the radius of the circle you want to make.

Use a finish nail with the head cut off as a pivot pin. To use the jig, find the center of your wood blank and make a small pilot hole, then mount the blank to the pivot pin on jig. The last method made me a bit nervous at first, but I just had to give it a try. Cutting circles with a table saw? Yes, it is possible. Trace a line across the sled, perpendicular to the blade, about half way front to back.

On this line, drill a pilot then drill hole on the line to match the radius of the circle you want to make. To use the jig, find the center of your wood blank and make a small pilot hole, then mount the blank to the pivot pin on the jig.

Start by slide the jig back and forth through the blade to cut off the 4 corners of the square blank. Continue to cut off the 8 remaining tips of the blank.

Then again to cut off all remining protrusions until your blank is as close to a circle as you can make it. Line up the line on your jig with the front tip of you saw blade, then use a magswitch or stop to lock the jig in the position.

Using push pads to protect your hands, rotate the blank clockwise into the blade in order to shave and sculpt it into a perfect circle. The router option is messy, but there's no limit to how big you can make your circle, like for a tabletop.

I prefer to stick with the upspiral bit all the way through. If you haven't already, watch the YouTube video for more details, and if you like what you see, subscribe to my YouTube channel. In my opinion, there is a hidden danger using the table saw method as you show. Of course, everyone knows that a table saw pushes back on the work, and that the work can jam against the blade, especially if the fence and blade are not set parallel, or the wood has locked-in stresses.

When the work is a many-sided polygon, pinned at its center, any backward rotation will cause a jam against the blade, VIOLENTLY kicking back the work and sled, and possibly leading to fingers contacting the blade!

I wouldn't even THINK about doing this without a guard in place, setting the blade as high as possible to minimize the pushback tendency , and setting the guard as low as possible to just clear the work.

Setting the blade high also gives truer cut when you get to the final "spin" pass. Your comment about bandsaw being limited in radius is true only to the extent you don't have room off to the side of the table. You can precut the corners off until you are less then that. You must set the pin carefully, accounting for the "lead" or cutting direction, or the blade will be pulled to the side, and produce a spiral and then jam.

Use a blade with a high tooth set. Avoid "thin kerf" blades. Set guides close and keep blade tension high. Another method to make circle is to first make template from scrap using your's or other methods , fastening this to the work, and using router with follow-bearing against the template. Reply 3 months ago. I don't understand your concern about a hidden danger with the table saw method, unless you're basing it on trying to trim too aggressively on the final rounding pass.

If that trim pass is taking off little more than the width of the blade, there's no chance of kickback. An advantage for the table saw is the relatively large supporting surface versus the small table of ordinary bandsaws, which makes it easier to get a square edge. You state that you are "uneasy" about the table saw setup. When wood binds against the blade, it is pushed back.

With usual table saw arrangement wood getting pushed directly in, fence parallel to the blade , backward motion tends to relieve the bind, and there is no tendency for the work to rotate because the binding force is in line with the pushing force. But in your setup, the wood piece is pivoted about the center point of the circle, which is laterally offset from the blade, and connected to a massive sled. If the work binds the blade suddenly, the inertia of the sled will resist moving back.

The offset force will cause the work to rotate about that pivot, toward the blade, causing the bind to get tighter, contacting the blade in the back. The only thing preventing this is the friction between the work and sled and your holding blocks, which is no match for the saw. The work will lift, and it and the sled will be shot back!

Once the work is roughed out, the danger of binding is little as the blade is not embedded in the work. For all of the cuts, setting the blade as high as possible reduces the amount of pushback, and keeping the cuts short so the back side of the up-moving blade is not contacted geometry more like the bandsaw setup.

Having a guard in place "protects" the high-set blade and prevents the work from lifting. The high setting also makes the sled position easier to determine, and the final spin-cut truer. I hope you have Saw Stop on that saw! I don't think you intended the last comment as a reply to mine, but I agree that setting the blade high is important. I had to cut a circle for the well about a year ago, two pieces of plywood with poly insulation in the center.

That was not fun cutting by freehand lol. Great tips, thank you for sharing! Thanks for sharing. For large circles I have used 2 dowels and one end has a rounded tip and the other I tape a marker on and use it like a giant compass and a hand held jig saw.

|

Sign Making Router Bit Set Keywords Soft Close Drawer Slides Adjustment Method Jointer Plane Diy 4d Jewelry Box Latch Hardware 2020 |

qelbi_siniq

26.07.2021 at 17:44:43

ROMAN_OFICERA

26.07.2021 at 13:22:56

polad_8_km

26.07.2021 at 16:50:56

dolce_gabbana_girl

26.07.2021 at 23:12:11