Router Diy Projects Data,Cabinet Slide Hardware Zone,Wood For Turning Mahogany - New On 2021

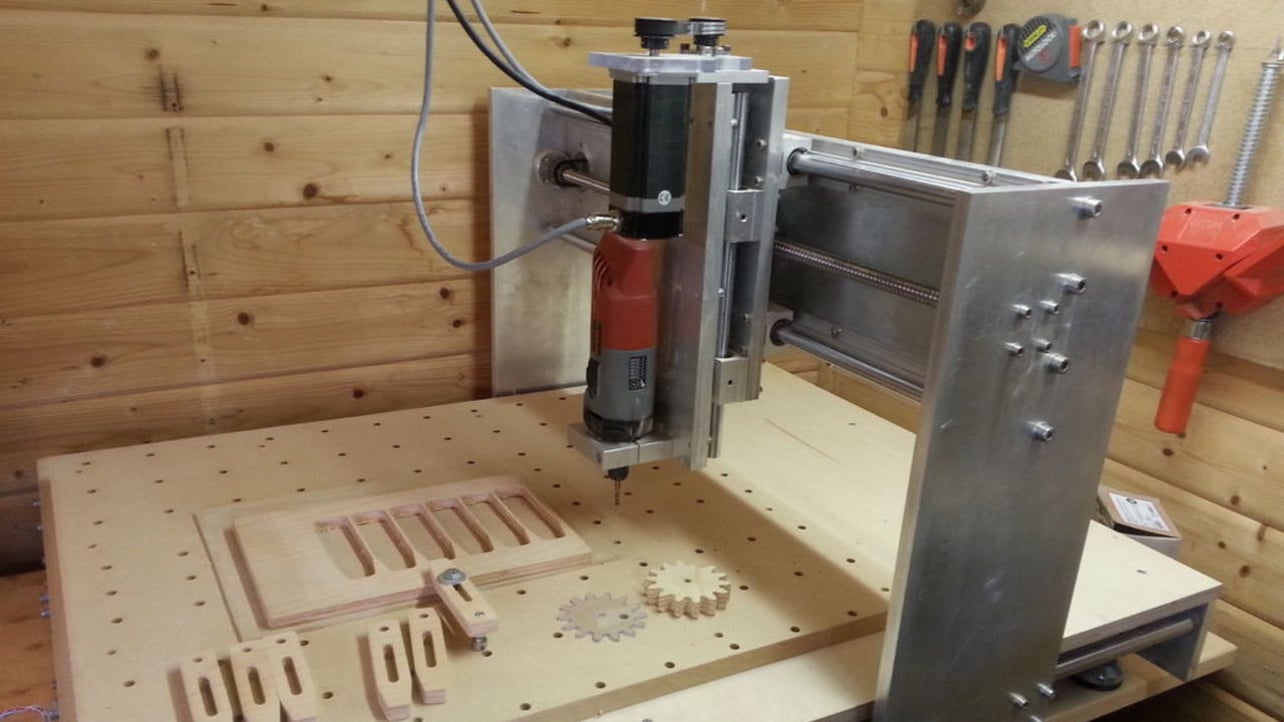

Home decor Farmhouse style decorating. Decorating with wreaths. Foyer farmhouse decorating. Front entrance decorating. Mindful gray Sherwin Williams painted walls. Front door. Hobby Lobby decor. White distressed letters. Architecture Art Design converted a split log into an elegant tealight holder. Routers can be used to cut patterns, grooves, and designs across multiple pieces of wood. Routers can also be used on flat pieces of wood to trace intricate designs or lettering.

Routers can be used with a jig to cut space for recessed door hinges or lock faceplates. Recessed hardware yields a more finished appearance and smoother operation. The 10 Commandments of Buying the Right Tools. Clever project ideas and step-by-step tutorials delivered right to your inbox each and every Saturday morning— sign up today for the Weekend DIY Club newsletter! Disclosure: BobVila. You agree that BobVila. All rights reserved. The tool comes in handy for many projects around the house, both functional and decorative.

The guard over the table fits over the bits to make sure they will not pop off and hurt the woodworker. Beneath the guard is the collet, which in turn sports a bit. You need to ensure that the collet is attached on firmly to be sure the bit stays constantly in place. Prior to making a cut with a table, ensure that the woodworking machine is held safely to the workbench or workspace in order that it cannot slide.

Slowly feed the wood through the bit, always keeping it in-line with the fence. That should produce a groove along the entire wood length. The way they work is a spindle from the woodworking router extends from the machine counter and spins generally at an RPM between 3, 4, It employs a vertical fence so that the workpiece can safely and effectively be guided to control the depth of the horizontal cut.

Generally speaking, there are three different types: a floor standing machine, a small benchtop machine, and accessories that you can bolt onto a table saw. You can even use one without a fence- in this case, a template is attached to the workpiece and integrates with a ball bearing guide and router bit.

Another way these woodworking machines can be employed is by utilizing a pain router accessory. The way this works is by using an overarm that arcs over the table and hangs directly onto the pin. Historically these woodworking machines came about as hobbyists and craftsman improvised them to get different depths of adjustments using a hole in the table surface.

There is a lot of debate regarding using a handheld router versus using one and a router table — while many of these devices are engineered to be stationary or handheld or mounted on a table.

When it comes to safety there are several tips that you should observe. Hearing protection and safety glasses are also advised when using one. Push sticks and feather boards are also helpful to ensure your fingers are kept away from the bit.

You should also make sure that you cover the bed using a guard. Long and narrow stock is readily worked on your router table. Feather boards help it become simple to work; they will support the stock tight up against the surface of the fence and table and allow you to focus on a gradual, consistent feed rate. Generally speaking, they can help you deal with stock dimensions that do not accommodate themselves to handheld woodwork.

Long and narrow stock, for example, which are employed to create mouldings and trim are extremely difficult to work on using a handheld router. Edge profiling several hundred or so feet of a specific door or base molding could possibly be achieved with a handheld tool and the help of special shop-built rigging, but doing so could be an incredibly unproductive option, when this tool table tends to make long runs of narrow stock easy to do.

Smaller bits of stock are also difficult to deal with using a handheld option. Handheld work on smaller components frequently involves a challenging balancing act.

You need to keep it completely vertical on stock that does not do a sufficient job of holding up the router base. To compound the issue, you need to have a means of keeping the stock itself in position when you work. Using one of these tables actually leaves your hands liberated to hold on to small parts while the table surface supplies a sturdy, flat support for the whole surface of your workpiece. Sign in. Log into your account. Forgot your password?

Password recovery. Recover your password. Home All Plans. The John Heisz Project 2. The Summerfeld Tools Blueprint 4. The Thinking Wood Workbench Build 5. The Wood Gears Horizontal Design 6. The Slot Mortiser Idea 7.

The Amateur Woodworker Project 8. The Ana White Rockler Blueprint The Ana White Cabinet Build The Crestwood Idea The Almost Free Build The Bench-Mounted Design The Garbage Can Dremel Idea The Instructables Idea The Reclaimed Desk Simple Project The Lakewoodies Design The Mother Earth News Idea The Rolling Maneuverable Project The One Project Closer Project The Dumb Simple Blueprint The American Woodworker Design The Table-Mate Idea Router Diy Projects Github The Deluxe Idea The Rockler Shop-Made Project The Wall-Mounted Design The Scott Moore Project The Start Woodworking Basic Build The Fold Away Idea The Quick And Easy Idea The Table Saw Fence Idea The John Heisz Idea The Plywood Idea The Converted Table Saw Blueprint The Cheap Folding Project Build The Minimalist Maker Design

|

Countersink Drill Set Js Sears Craftsman Band Saw 10 Inch Engine Pumpkin Carving Kit Kat Commercial Review Home Depot Waterloo Online Shopping Facebook |

ARMAGEDDON

04.03.2021 at 23:13:56

Bratan

04.03.2021 at 21:58:18

Princessa

04.03.2021 at 23:39:42

Natalyu

04.03.2021 at 18:45:32

Drakon_666

04.03.2021 at 13:34:48