Making A Router Box Joint Jig Fail,Build A Frame Duck Blind Water,Diy Wood Door Projects In China,Mortise And Tenon Jig Lowes Facebook - Easy Way

I found a chunk of colonial casing and trimmed the mitered ends for aesthetics. I glued and screwed it to the front of the base. TIP: If your clamps ever lose one of the rubber cushions just use one of those thingies you put on the bottom of a chair to protect the floor. The glue is not the best and it is advisable to add a little daub of super glue to it. I found a chunk of 2 x 4 and used it as the back fence and ran the router blade up to it.

I screwed the fences through the base and counter sunk the screws. Make sure this fence is square to the base. I've seen some people secure right angle wedges to the back of the fence to keep it square.

It took me a bit of finessing, but eventually I got a perfect fit. I cut two pieces. One is secured to the base and is one router bit width away from the cut made by the bit.

The other is used to basically eliminate any space and will allow the router bit to cut a hole in the end of a board.

I raised the router bit a skosh above the thickness of the wood I'd be using. It is easier to sand off a protrusion than to fill in a depression. Then ran it into the rear fence and tested the keys. I made that error and knocked out the key and trimmed it down and the spacer down to the proper height. Now to test the jig. I cut two pieces of wood the same size.

Then I removed the spacer and staggered and aligned the two notches on and up to the fixed key. It then became a matter of leap-frogging over the key until I reached the end of the board. The same result can be gotten by doing each separately. The first goes against the permanent key, the second goes against the spacer. Basically, you are creating tongues and groves that will go together to form a joint. I was very pleased with the result.

Now I must admit I looked at dozens of How Tos on making this jig and Frankensteined my own version to fit my router. You'll notice I only have one runner where as most I saw have two. Even one I saw made a second runner off the side of the table. Some were so elaborate it'd take me forever to build it. The simple one I show here took a few hours on and off while doing other things around the house.

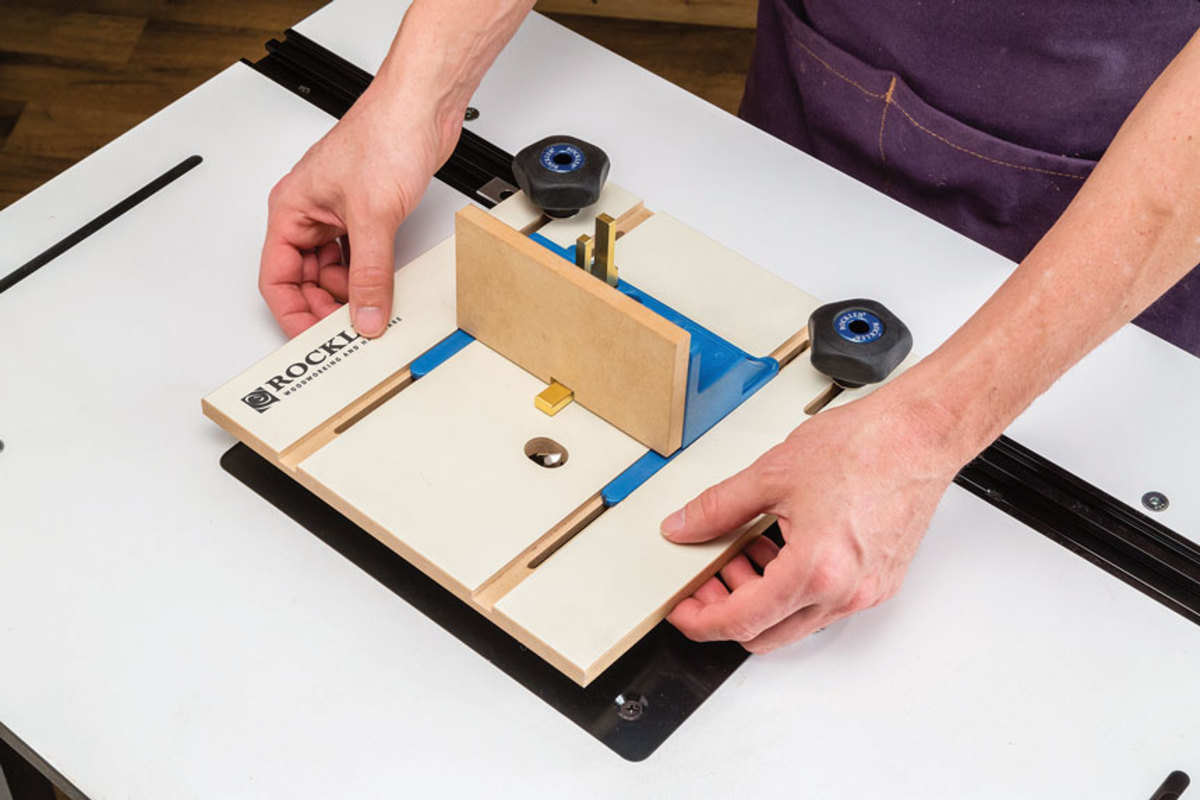

It meets my needs, and that is the whole purpose. Make a jig to suit your personal requirements. I'm making my jig now. One question. What amount to two separate factors for some other box joint jigs are simplified into a single adjustment here. The chrome dial on the end of the red knob tweaks joint fit further, in. The fence adjusts laterally on the miter bar to suit different cutter-to-miter slot distances, as these vary by router table and table saw.

This jig also offers excellent guarding, with thick MDF blocks on the infeed and outfeed sides, plus a long clear guard plate shielding the user from flying debris or contact with the cutter. That flexibility can help you produce a balanced joint pattern on a wide variety of workpiece widths.

Be sure to keep these guides handy unless you cut box joints frequently — there is a learning curve to setting up the I-Box. The versatile RTJ will cut about a dozen sizes and styles of through and half-blind dovetails, plus four sizes of box joints. It consists of a thick aircraft-grade aluminum template with a pattern for cutting dovetail pins or box joints along one edge and dovetail tails along the other edge.

While the RTJ will cut Making A Router Box Joint Jig In a few sizes of box joints, most other template-style dovetail jigs can, too. What makes this jig truly unique is its handle and fence system. Leigh has engineered a series of holes and slots in the template that position the fence automatically for cutting its full range of box and dovetail joints.

The bushing portion is elliptical, not round, like typical guide bushings. Its collar has numeric index marks that enable you to adjust the tolerances of your joints by simply twisting the eBush left or right to increase the collar-to-router bit offset.

This way, eBush allows joints to be fine-tuned in. A clearly illustrated spiral-bound manual, and an instructional DVD, provide excellent help. Not many. But remember, box joints are only the tip of the iceberg of joint-making options here. It functions like a double-bar miter gauge: the sled supports your workpiece while cutting pins and slots so you can slide it over the bit accurately.

These keys, when used with router bits of matching diameters, enable the Making A Router Box Joint Jig Effect jig to cut three sizes of box joints with minimal changeover. To switch to another joint size, just swap the index bar and bit to the size you want to cut, then loosen and shift the jig base over accordingly to match the bit and key size.

|

Titebond Liquid Hide Wood Glue With 9 Undermount Drawer Slides Free Woodworking Projects Plans And How To Guides Your Under Shelf Drawer Amazon Germany |

Aska_Padnoska

05.02.2021 at 12:48:53

TeReMoK

05.02.2021 at 16:59:21

AYSEN_RAZIN

05.02.2021 at 19:46:48

BABNIK

05.02.2021 at 10:26:30