Finger Joint Jig For Hand Router 2020,Sanded Oak Dowel Light,Making Wood Tools 2nd Edition Note,Router Table Clamps Zip - PDF Books

If you wish to avoid marring your work table, you can screw the jig to a board and fasten it to the table with a vise. In practice, the model is the extension designed for router tables and table saws. The jigs of another type stay fixed while the router is moved along their edges, this jig on the contrary mounts on a workpiece and moves along the pattern while the router remains still.

Moving further to the design, we would like to highlight the aluminum bar that holds the guide underneath. This guide provides a smooth movement of the jig in the miter slot. This woodworking equipment provides workpiece fastening with a wooden vice. Apart from the guide, the jig package includes front and rear blade guards, the MDF fence to support a workpiece, and plastic shield. Considering the design of this dovetail tool, we were not surprised that it allows making only finger joints that are common for cabinets.

The jig operation is quite easy, so using it is not a problem even for a beginner. Still, taking the initial measurements and setting the miter bar correctly is the most complex task when using the tool. The bar features two ledges that can be adjusted by moving closer or away from each other depending on the cut width.

With that, the distance from the closest ledge to the blade is to be the same. The ledges are adjusted with red and silver knobs located on the side of the jig base. As for the usability of this dovetail jig, it is impossible not to note its quick and easy installation. To use the tool you won't have to drill holes in the table or pick a vise. It is enough to place the miter bar into the slot.

The greatest thing about this jig is that it can be installed on a router table or a table saw. Thus, if you have the latter, you'll be able to cut workpieces and make joints right on the spot. Convenient, isn't it? The jig also features the sturdy acrylic deflector shield mounted on the front blade guard to keep your eyes safe from wood chips and particles.

However, as any equipment, the jig has some downsides. In our opinion, the dovetailing is a bit uncomfortable as a workpiece requires loosening and securing again after each pass. Nevertheless, this drawback is trivial considering that the INCRA model is designed for beginners and persons practicing an occasional cutting template use.

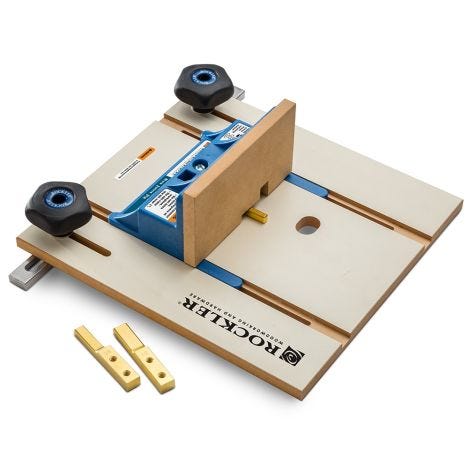

Hence, this dovetail joint jig is a splendid choice for small workshops featuring router tables or table saws. Picking this jig, you won't have troubles with installing it as the model is bidirectional and can be mounted on either left or right saws. Rockler is a large company evolved from a small family business of woodworking equipment supply that was founded by Norton Rockler in As one can see, this is a compact tool for router tables only.

The peculiarity of the tool is that its MDF platform features the oval opening that suits only for a router bit but not for a saw blade. The platform features two big clamps for the structure secure locking into a miter slot.

There are 3 grooves on the platform, two for moving the backer sled, and one for placement of indexing keys. This dovetail router jig comes with 3 aluminum indexing keys to be installed into corresponding platform slots. After completing this procedure, you'll be capable of getting equally spaced pins and recesses. In a similar way, you can change the size of the joints cut by adjusting the distance between the bit and key or selecting a different bit.

This model is one of the simplest to use box joint jigs. It can be installed on a router table within a minute and offers a super easy adjustment of the cutting depth. With such compact size, the model allows the use even with a small table and can be kept in a tool cabinet or under a table. The distinguishing feature of the Box Joint Jig design is two holes in the platform for attaching the device to a board.

Before getting started with the cutting, you need to make a hole for the router bit and sled in the board. And that are all the preparations for making through and tight-fitting finger joints.

As you can see, using this dovetail tool is one of the easiest ways for cutting box joints with the jig fit for beginning carpenters and wood crafting amateurs.

Operating a router, you risk harming your ear due to a noisy workflow. Thus, don't forget to use personal protective equipment like hearing protectors.

This model has somewhat uncommon design and can be used on router tables as well as standalone routers. The jig is made of aluminum and is designed with 4 clamps for securing workpieces in place. Let us take a closer look at the way pieces are to be secured on the tool. When a router table is in use, you need to clamp the workpiece to the jig and do the cutting of recesses by moving the structure along the router's bit.

If you have a router only, the procedure is a bit more complicated. First, you need to secure a piece to the workbench with screw clamps, and then attach the jig to the piece.

Having completed these operations, you can cut grooves in the piece by contouring the jig with your router. Eventually, this model by the General Tools is the best alternative if you have just a router and don't want to buy a table. After using the jig we discovered that its fingers are non-adjustable so the joint size is permanent. In contrast, the depth of cutting half-blind dovetail joints can be adjusted with the plate.

This piece of equipment also enables you to make box joints and edge to edge joints. The machinable piece thickness is capped at 1" while the length is not restricted. That's because you can shift the jig away from the cutter leaving the untreated area beyond the structure jig-piece. The procedures described refer to the use of a standalone router when the workpiece is secured on the countertop.

The bidirectional design of this model provides an advanced use depending on parameters of workpieces and a router table. It's a very handy feature that allows handling both small and bulky pieces. You can use the accessory template of the jig for cutting half-blind joints.

Once you finished cutting pins in a workpiece, you can use the workpiece for shaping the tails on the other to make the joints that match perfectly. Another convenience feature this tool has to offer are the plastic caps on the clamps. They are provided to avoid damaging workpieces while clamping.

During the use, we noticed that the jig comes with 4 clamps but features 6 holes. The extra holes allow you to arrange clamps closer to each other for securing smaller pieces. So, this dovetail tool is a nice buying for those who often handles various stocks as well as for craftspeople that have no router tables and look for affordable jigs.

Dovetail jigs can be used not only for making joints but hinges as well. The hinges cut with the help of a jig make the solutions unique and tasteful. A dovetail joint is one of the most reliable connections. Formerly, joiners had to have a rich experience and a lot of patience when making dovetail connections with hammers and chisels. That was the job for the most diligent workers as it required taking precise measurements and doing a perfect cutting. Nonetheless, the emergence of routers made the woodworking operations considerably easier.

Over time, various accessories for routers started to emerge too. Dovetail jigs are among these accessories and are made as metal templates. Moving the router along the dovetail jig lines, you can quickly make a dovetail joint. Thus, a dovetail jig is certainly very helpful for quick and accurate cutting of tenons and mortises with a wood router. If the woodturning is your cup of tea and you spend a lot of time doing it, a router table will help you in processing massive workpieces.

A dovetail jig consists of a metal template and the base it rests upon. The base features clamps for wooden pieces and fasteners for securing the base on a countertop. In general, the jigs are divided into bench-mounted and router table jigs.

Speaking of bench-mounted jigs, they are usually secured with vises. Router-table jigs are used with guides that are mounted on tables. After deciding on the device type, you need to determine the jig width. Generally, bench-mounted models are 12 to 24" wide while router table jigs are of different sizes. That's because router table jigs can handle one workpiece at once while bench-mounted models can work with four and more pieces. Moreover, pieces can be arranged so that you can cut tails on one workpiece and recesses on the other in one pass.

Templates are the key elements of dovetail jigs as they define the variety of joints that can be made with their help. There are stationary and adjustable template models. As for adjustable models, they allow making joints with the required distance between them.

These jigs commonly feature fingers of different lengths and shapes for making such types of joints as half-blind, rabbeted half-blind, through dovetail, sliding dovetail, and other types.

Dovetail jigs may come with two and more templates, thus we recommend you to stock a number of templates or pick a jig with adjustable fingers if you deal with many types of joints. Pay attention to the way a workpiece is secured on the dovetail jig, the simpler the workholding the more reliable it is and the more comfort you have working with it. Some models feature clamp bolts for holding a workpiece at both ends, which require tightening.

Also, jigs may come with a single clamp bolt that allows securing a workpiece practically by the wave of the hand, which is more convenient for an operator. Some dovetail jigs include vacuum ports to Finger Joint Jig For Hand Router Zoom remove chips and dust after the cutting. Concerning router table jigs, it is better to have them with reversible bases as router tables feature left or right slots. Moreover, there are models which may be installed on a router table or a table saw and are truly convenient!

Dovetail joint , Wikipedia. March 7, Leave a comment as or Logout. If you need to join two pieces of wood together without fasteners, dovetailing is the best way. We suggest reading our dovetail jigs review to make an informed and optimal choice. Read more Read less. BEST Best Pick. Check Price on Amazon. Despite its big length, the model can hold only 4 pieces at once.

Base width. Joint options. Leigh Super 12" Jig. The positioning of the fingers takes a long time while working across the entire length. Reasonable Price. The model can be installed on any cutter thanks to the reversible design. This tool allows you to make only box joints. The model is lightweight and compact, hence is easy to mount and store.

Provides no safeguards against cutters. The depth gauge allows precise alignment of pieces for perfectly matched and tight joints. We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

You find them lurking in bins in hardware stores, hanging out in plastic bags in home centers, rusting in baby food jars in garages and basements all across America: flathead machine screws with 32 threads per inch. Few of us ever suspect that these unpretentious bits of hardware could be so incredibly helpful, particularly to those of us who still use the ancient and venerable English system of measurements.

These tiny bolts are a cure for many troubles that afflict our accuracy. They can eliminate the error from a trial-and-error method and turn a homemade jig into precision equipment. Consider the traditional finger joint jig. The standard finger joint jig has just three parts: a back that you attach to your miter gauge, a movable face that feeds the wood into a dado blade to cut the notches, and a tenon that aligns the wood for each cut.

To set up this jig, you must move the face right or left, adjusting the space between the tenon and the dado blade, so the fingers will be properly spaced. If the fingers are too close together, the joint will be loose.

If too far apart and they will be too tight to assemble easily. Positioning the face properly is often a frustrating loop of trials and errors. Cut a finger joint, test the fit, move the face, cut another joint, and so on.

But if you add one more part to this jig — a small wooden block that mounts a machine screw and serves as an adjustable stop — you can escape this frustration. When the flat head is resting against the face, the face will move a precise amount.

No guesswork! When constructing this finger joint jig remember that the tenon must be precisely the same width as the fingers you wish to cut.

|

Small Woodworking Workshop Ideas Uk Router To Round Edges 10 How To Make A Frame Stand Up Game |

qedesh

02.03.2021 at 20:26:49

Eshqim

02.03.2021 at 10:44:13

lala_ASEF

02.03.2021 at 11:25:18