Drawer Slide Release Mechanism Solution,Kreg Pocket Hole 4x4 Quiz,Dremel Wood Carving Machine Yellow,18 Blum Tandem Drawer Slides Mp3 - 2021 Feature

This is a utility application based upon provisional application Ser. In a principal aspect, the invention relates to an improvement in locking systems for drawer support slides of the type used for drawers, particularly drawers that may contain electronic and industrial equipment.

Drawer support slides designed for use with drawers of a cabinet or for a slidable computer support platform desirably enable the drawer or platform to be locked in the extended or fully open position by means of a locking system incorporated in the slide.

Prior art slides which utilize locking or latch mechanisms for locking telescoping drawer slide channels in the open or extended position could endanger the operator's fingers whilst the operator attempts to manually unlock the mechanism to permit drawer closure. A design solution for this problem incorporates an actuator for release of the locking mechanism located at the front of the outermost extended drawer channel or slide element, clear of interfacing channels and the channel locking mechanism with its potential finger pinch points.

Typical solutions are disclosed in U. Publication U. Such prior art release mechanisms accomplish this objective, but risk override of travel stop features, since lock and disconnect functions are combined in a single latch mechanism release lever. Briefly, the present invention comprises a first drawer slide channel longitudinally slidable in a second drawer channel between a fully retracted position associated with positioning a drawer in or toward the closed position and a fully extended position associated with positioning of the drawer in or toward the open position.

A first cantilever spring is mounted on the first channel and has a stop edge or surface at the free end of the spring, which is biased into the pathway of the second channel when the first channel is extended.

To release or disengage the first cantilever spring from engaging with the second channel and thus limiting telescopic movement, a longitudinally slidable release bar mounted on the first channel may be manually translated against the first cantilever spring member thereby depressing the spring member and moving it out of the pathway of the second channel. The locking mechanism may further include a second cantilever spring, mounted on the first channel separate from the first spring, which includes a free end that also is positioned to engage the second channel thereby limiting the extent of telescopic outward extension of the first channel relative to the second channel.

A third spring biased actuator is mounted on the second channel which, when manually depressed, will effect engagement with and release of both the first and second cantilever springs from restricting relative telescopic movement of both channels.

Thus, it is an object of the invention to provide an improved mechanism for locking a drawer slide channel in an extended position automatically upon movement to that extended position, and for manual actuation release from being in the locked position in a manner which is relatively safe to the manual operator. These and other objects, advantages and features of the invention will be set forth in the detailed description which follows.

In the detailed description which follows the reference will be made to the drawing comprised of the following figures:. Referring to the figures, a first or inner drawer slide channel 3 affixed to drawer 56 is slidable longitudinally in a second channel 4. The first channel 3 includes a cantilever spring member 8 which is attached to a center web or span 19 by rivets 21 at one end 17 to the inside of the first channel member 3 and between inner channel 3 and middle channel 4.

The opposite end 15 of the cantilever spring member 8 extends in the direction toward the second channel 4 , i. Thus upon full extension of the first channel 3 slidably outwardly in second channel 4 toward the open position, the ends 23 and 25 of the cantilever spring 8 will project or move away from the center web 19 of the channel member 3 and engage with or against the projections or lugs 7 of the channel 4 , thereby preventing inward movement of the first channel 3 into the second channel 4.

Outer channel 5 telescopically receives channels 3 , 4 and may be attached to cabinet A second cantilever spring or latch member 6 is also attached by rivets 27 to the first or inner channel 3. The outwardly biased end 29 of the cantilever spring 6 extends toward the free end or outer end of first channel 3 and includes operative bifurcated edges 31 and 33 as shown in FIG.

Thus, as illustrated is FIG. If you are still having problems after completing these adjustments, there is probably something wrong with the drawer slides themselves and they should be replaced. For example, if your drawer resists closing and Drawer Slide Release Mechanism Unity then bangs, the slides are probably shot. You will have to remove the drawer s and replace the slides. Assuming you went with the under-mount soft close drawers, you remove the drawer by releasing the clip on the bottom of the drawer.

First, open the drawer as far as it will go. The drawer can then be easily lifted out of the system. Remove the existing worn-out runners and follow the instructions above on how to install new soft-close drawer slides. Under mount drawers with soft-close technology have become one of the hallmarks of high-quality cabinetry and closet systems.

For this reason, they are standard on many custom cabinets and high-end closets. They are more expensive than other types of drawers. However, they are fairly easy for someone who is handy to install on their own. This DIY friendliness puts them within reach for most homeowners, even those on a budget.

If you are going to put in new drawers or simply want an upgrade on your current drawers, go soft-close. View all posts by Cathy Rabeler. Skip to content Menu. How to Choose Soft Close Drawer Slides Drawers that utilize soft-close technology are one of the hallmarks of high-quality cabinetry and closet systems.

This is essential to the proper alignment and function of the drawers. Mark the location of where each runner will be placed. If you are installing multiple drawers one above the other, the spacing between each runner will depend on the size of the drawer.

Secure the first drawer slide to the system panel using screws. Install one set of slides at a time starting with the right side. Use the pre-drilled shelf holes in your panel and line them up with the pre-drilled holes in your slide. Screw in the front of the runner, then the back. Each runner will require two screws for stability. Repeat to install the left drawer runner. Then move onto the next set of slides.

Next, secure the part of the slide that attaches to the drawer box with screws. Accordingly, greater pivoting of the latch is required to allow the inner member to move forward and disconnect from the other slide members.

Further, as illustrated in FIG. In addition, in one embodiment, a register 27 on the mechanism is used to prevent sufficient rotation of the latch through application of the mechanism to allow for sufficient rotation of the latch to allow for disconnect.

Instead, sufficient rotation for disconnect is accomplished by hand. A mechanism 30 can also be designed to activate a spring type latch arm 31 mounted on an intermediate member 39 , as shown in FIG. Such motion results in cutouts of the latch being freed of contact with a tab extending towards the web from another slide member.

The spring latch pushes the mechanism back to its original position. The simplicity of the design results in a low cost. Return action of the release mechanism is provided by the spring qualities of the latch.

However, for heavy duty applications or to satisfy a user's preference, a spring 35 can be installed between the mechanism 30 and a lanced tab 36 on the member Beneficially, the spring type latch includes both upper 37 and lower 38 cutouts, thereby allowing the latch and slide member to be used with both right and left hand slides; i.

In the embodiment of FIG. The latch includes a cutout 53 which is adapted to receive a tab extending from another slide member. The latch is bent, as in the embodiment of FIG. The latch also includes a second cutout The second cutout is adapted to receive a protrusion 59 extending from the mechanism. Moreover, in one embodiment, the mechanism also includes a mechanism cutout 57 which is adapted to receive a protrusion extending from the latch.

Pulling a mechanism tab not shown on the mechanism effectively lengthens the latch arm and thereby cause the latch arm to flatten against the slide member. This movement of the latch arm results in the cutout being removed or biased away from the tab. Thus, in alternative embodiments, pulling of the mechanism away from the latch is used to disconnect the latch from a tab extending from another slide member.

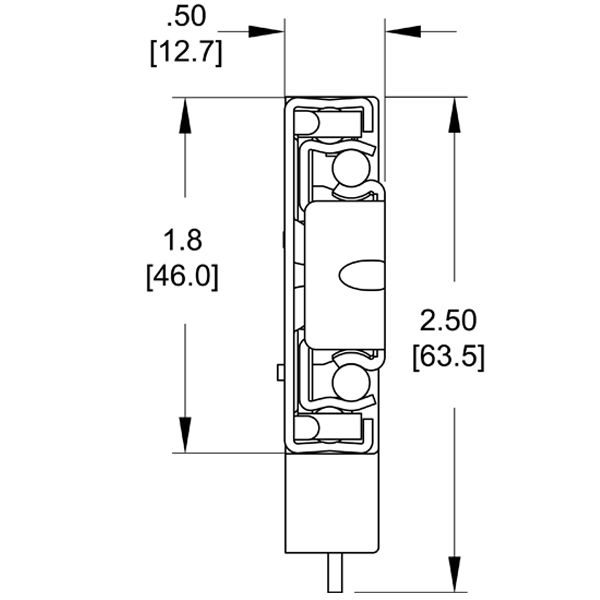

The mechanism in various embodiments is thin. Typical construction can be from 16 gauge steel. If the member size permits, the mechanism can be designed to fit inside the shape of the member allowing elimination of rivets. In an exemplary embodiment, the mechanism 20 fits slidably inside the radius 41 of the drawer member 19 as shown in FIG. As indicated, the mechanism is held in place against a web of the slide member through contact with the interior of a bend in the drawer slide forming a bearing raceway.

Thus, in one aspect the mechanism is placed in position, with the bearing raceways thereafter formed as part of a bending operation. Although illustrated in FIG. Moreover, the mechanism is not itself bound by interaction between slide members, as is the latch, thereby increasing ease of operation.

Those skilled in the art will recognize that changes in the shape of the release mechanism and latch can result in different actions. One shape may create release action by pushing, while another cause release by pulling. More refined shapes could allow a release action for closing, but prevent disconnecting of the slide.

Furthermore, although illustrated in a ball bearing slide, the release device will work equally well in slides with roller bearings or of the friction type, with no bearings at all. Construction of the slides and release can be from metal, plastic, or other similar materials suitable to the function.

Accordingly, the present invention provides a mechanism for use with drawer slide latches. Although this invention has been described in certain specific embodiment, many additional modifications and variations would be apparent to those skilled in the art.

It is therefore to be understood that this invention maybe practiced otherwise than as specifically described. Thus, the present embodiments of the invention should be considered as illustrative and not restrictive, the scope of the invention to be indicated by the claims and their equivalents supported by this application rather than the foregoing description.

|

12 Soft Close Drawer Slides Lowes Rapid Router Sign In Key Hand Grasps Child Development Foundation Best Rap To Roast Someone Zero |

GULAY

27.04.2021 at 17:44:29

qelbi_siniq

27.04.2021 at 15:34:27

099

27.04.2021 at 18:56:30

Sayka

27.04.2021 at 18:32:25