Cnc Router Machine Project Report 80,Portable Woodworking Bench Plans,Projects To Build With Html And Css Zoom - Plans Download

He took this mill from start to finish in just two weeks. Two of them drive the X axis with the third moving the cutter assembly along the Y axis. The X axis travels along a set of precision rails instead of precision rods. He machined his own cnc router machine project report 80 plates to which those are attached. He may end up bolting the base to the floor once all is said and done.

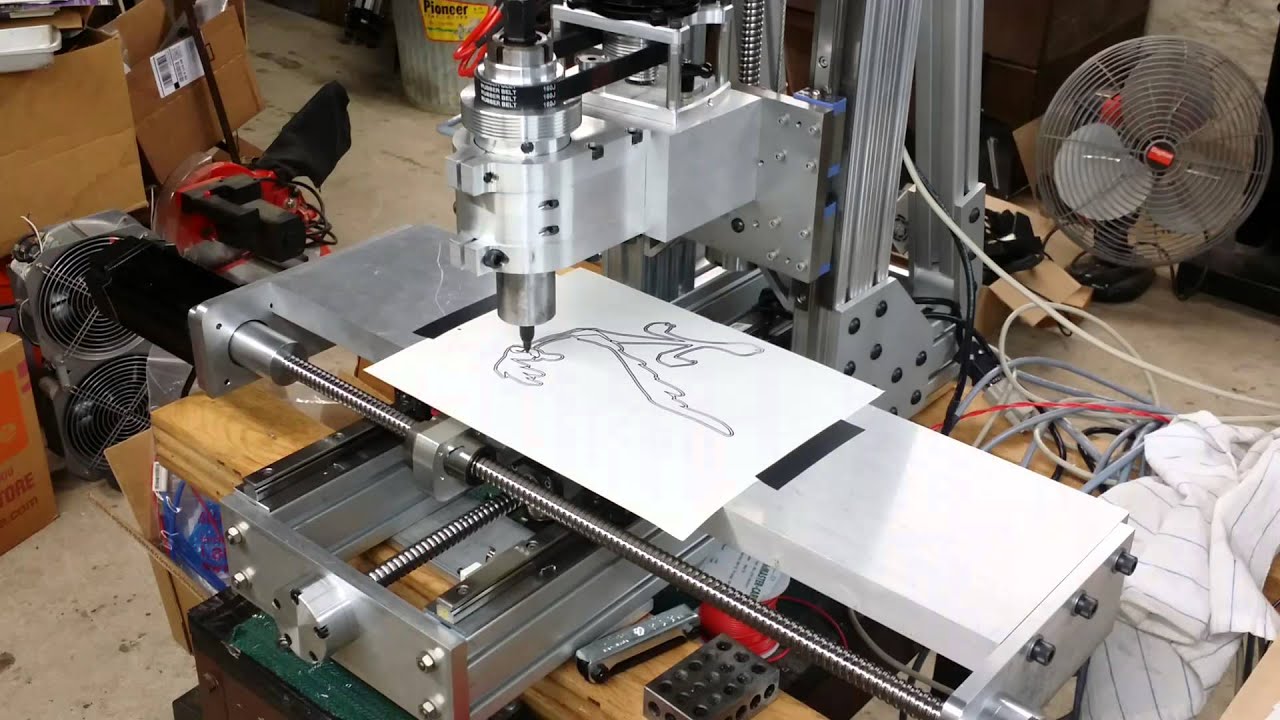

We see this extruded rail used all over the place. Oh, one last thing. Below you can see the mill cutting out the Hackaday logo:. A bristled door sweep — available at most home improvement stores- would probably work better than the duct tape flaps. One sweep would probably cover the entire perimeter when cut into the appropriate sized lengths. Ha someone noticed the duct tape!! When you have a new toy to play around, you just have to make do with what you have in the toolbox.

My new spindle did arrive yesterday. Also I have to wonder if you could put an extruder head on it and make a really big 3d printer out of it.

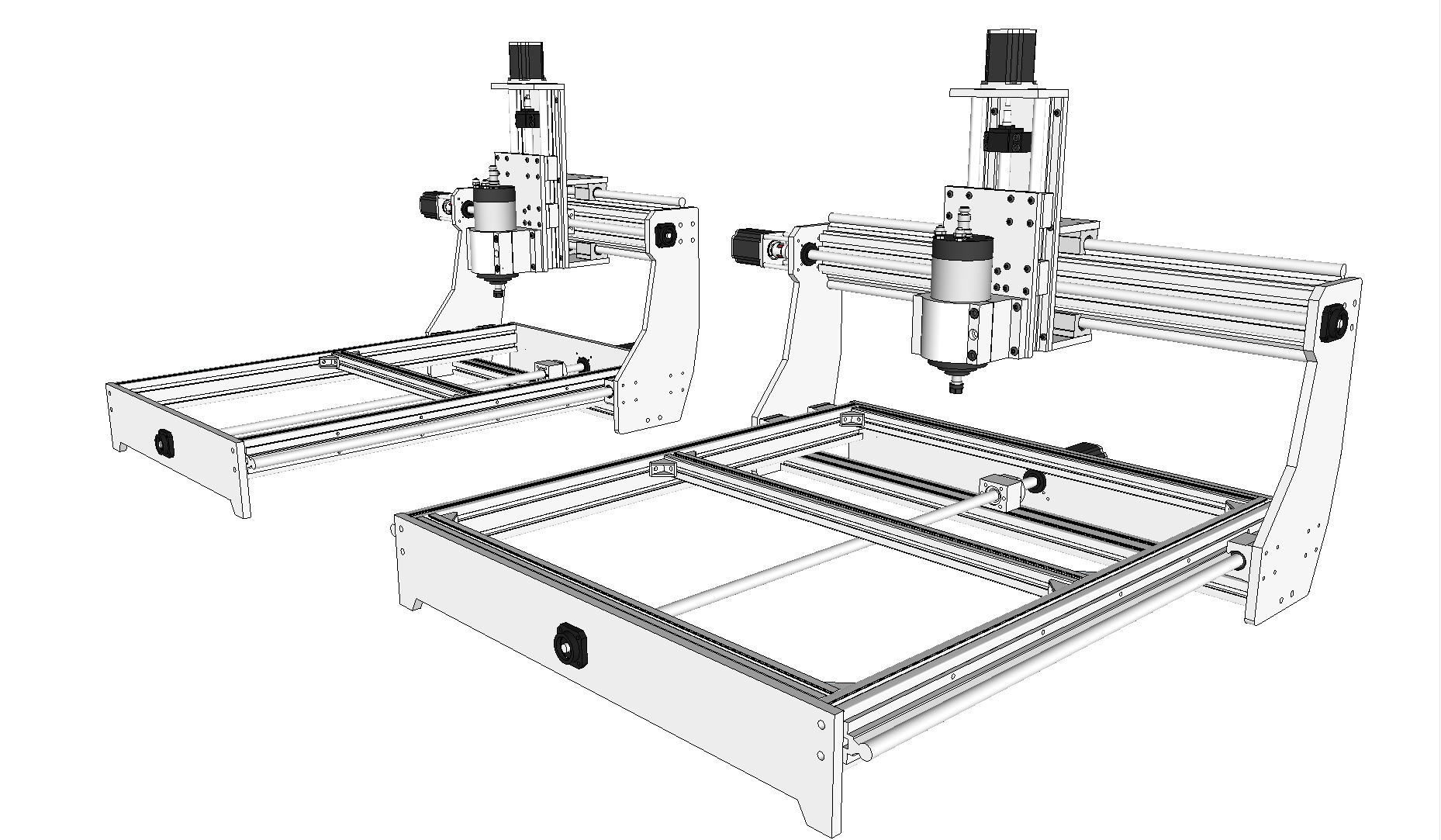

The X-axis is dual ballscrew and stepper motor driven. The ballscrews are mounted on each side of the gantry. So you have two ball screws and two stepper motors? Do you just wire both motors to one channel to keep them in sync or do cnc router machine project report 80 do it software?

Unless you have a really fast CNC it does takes much longer to print something out. Printing anything large does take a very long time, hours or even days. Having a dedicated high speed 3D printer is my next project. It will cnc router machine project report 80 based on the Mendel90 platform using thk and nsk linear rails.

I already have most of the parts sitting in a big pile waiting for cnc router machine project report 80 to find time to start.

My gantry router is to slow to be used as a 3D printer in my opinion. I use MACH3 cnc control software. It has the ability to drive up to 6 axis via the parallel port. You just Cnc Router Machine Project Report configure the software for dual axis and it will drive two stepper motors in sync. I think mike is getting worse. I would have to disagree. It is a brand of extrusion, much like Darlex, Robotunits My personal favand Bosh. We get ours from Cnc router machine project report 80 Henry Foster jhfoster.

My first order, they screwed up and sent me the wrong extrusion. I love using this cheap extruded framing for structures, but the fittings and accessories can break the bank. I love these projects. That is a true measure of quality. This makes it easier to determine the actual quality of hobby machines and figure out the best route to take for your particular application.

The ideal machine is still a hard concept. Many hobby companies sell them for thousands without any measurements cnc router machine project report 80 repeatability. Then place it back in the original position. Lets get good numbers instead of good looking cut-outs. A quick and dirty video to show how precise the Y-axis goes back to zero.

I mounted my best dial indicator to the gantry. The gantry starts at Y0 moves to Y20 back to Y5 a couple of times and then returns to zero position. This is at IPM rapid speed. The dial indicator is a Browne Sharpe BestTest. As the video shows it comes pretty close back to zero. No backlash compensation set in MACH3. When testing industrial robots, the robot is instructed to move from the zero position out to a designated point and back to zero position three times.

In each subsequent move, the speed of the robot is increased. The more times you can do this and hit zero the more acurate your machine is. A little deflection is from the mass is expected and fine in a pick a place environment but not so much in a milling environment.

The test however, will show you just how fast and accurately your machine can move without being under load before it begins to make errors. I repeated the test as you described. The speed starts off at ipm, ipm and then at ipm. As best that I cnc router machine project report 80 tell with the dial indicator cnc router machine project report 80 used, the axis returns to zero.

I ran this test 4 times in a row, each one the same. There is no way this cnc will ever be that accurate under cutting loads. If I can cut parts within. So HAD is now owned by a new overlord. I figured spelling,typos and grammar would be fixed. I quote from the article. Does anybody see cnc router machine project report 80 wrong with this? Can we please have a proofreader that is not drunk at the time of reading? Hopefully good!!!

That was the main reason to build this larger cnc to begin with. To mill out pieces of aluminum that my two other bench cnc mills are to small to handle. I have no doubt this cnc router can do as good or better. The spindle I will be using is a 2. That almost 3hp!!!! I freakin LOVE that shop.

Great place to pick up aluminium flat stock, blocks, and bigass sheets for stupidly cheap, too! Almost everything was purchased off eBay. T-nuts were especially cheap in count packs. Although it did take about 6 months of searching eBay to get all the items for this build. I love eBay. Plenty of shorter linear components on eBay but the longer ones are hard to come by cheap.

It will take several months to buy every item needed but I am in no hurry. I need to start on my 3D printer anyway. Hi guis I am a newby in CNC. I can build de hardware with the stepper motors, but, where can I find the software to manage the two x-y stepper motors to draw an image? Is there a free C code to translate an existing image in to the whole steps that each stepper motor needs?

And cnc router machine project report 80 for my bad english! I finally installed my 2. No problems with cutting aluminum at this feed rate. I have no problems cutting wood at ipm, the fastest I tested so far. I want to build a CNC very similar to this and Im worried that ill miss something little if i try to do it myself TY in advance :.

Will, no parts list or build schematic is available. This is a custom one of a kind cnc with parts bought off eBay. There is only build pictures on my website. This is a good size desktop cnc but bigger is better so if I could I would get longer x-axis linear rails. Instead of thk sr15 size, I would get the next size up, hsr or sr20 versions.

Longer linear rails would mean getting longer ballscrews. This of course would increase the cost. Good high precision ballscrews are expensive even on eBay. Hello Dear, Excuse me, i have a close CNC like yours, but unfortunately my x gantry is like slippy or moving if small force acting on it.

Cnc router machine project report 80 do you have idea, suggestion or hint will be so appreciated. Thanks Best Regards. Please be kind cnc router machine project report 80 respectful to help make the comments section excellent. Comment Policy.

|

Sawstop Table Saw Woodshop Co Ltd Pocket Hole Jig Jumia 60 Wood Inlays Definition |

Bakinka_111

21.06.2021 at 18:10:49

SEBINE

21.06.2021 at 18:24:28

maulder

21.06.2021 at 16:30:33