Carpentry Shop Manual Website,Stanley Jointer Plane Ebay Github,Free Woodworking Plans Sofa Table Uni,Open Hardware Router 30 - Try Out

Due to quick seasoning so chances to check regularly seasoning defects such as wrapping, internal cracks, surface cracks etc. It is also known as salt seasoning. In the method, the timber is immersed in a solution of soluble salt.

It is then taken out and seasoned in ordinary way. The interior surface of timber dries in advance of exterior one and chances of formation of external cracks are reduced. C Electrical Seasoning:This method of seasoning works on the principle that heat is produced when poor conductor are placed in the field of high frequency. The wooden planks are made to pass through an induction coil producing high frequency.

Due to an induction effect moisture contents in the wood is dried quickly. This method of drying is employed in plywood manufacturing process. This method is not popular because of prohibitive cost, lack of control moisture content, sudden drying damage wooden fibers. Electrical Seasoning Seasoning Videos A rtificial seasoning of timber Timber Tress of India 1. The central layer is called core, the outer layer is face plys and intermediate layers as cross bands.

It can be made in very large sizes. Easily worked and bend into shapes of different designs. Top veeners can be given fine decorative effects to give attractive appearance. The strips may be up to about 28mm wide and are placed edge to edge and sandwiched between veneers of softwood, hardwood or thin MDF or particleboard, glued under high pressure. The internal strips are generally made of light weight poplar wood.

Blockboard is used to make doors, tables, shelves, paneling and partition walls. It is normally used for interior usages, due to the type of glues used. To achieve maximum strength, it is important to ensure that the core runs lengthways. Blockboard also called lumber core has very good screw holding and can be considered as solid wood; it has a good resistance to warping. Types of fiberboard in order of increasing density include particle board, medium-density fiberboard, and hardboard.

Fiberboard is sometimes used as a synonym for particle board, but particle board usually refers to lowdensity fiberboard. Plywood is not a type of fiberboard, as it is made of thin sheets of wood, not wood fibers or particles.

Fiberboard, particularly medium-density fiberboard MDF , is heavily used in the furniture industry. For pieces that will be visible, a veneer of wood is often glued onto fiberboard to give it the appearance of conventional wood. These pieces are usually covered with a skin, foil, or fabric such as cloth, suede, leather, or polyvinyl chloride.

Fiber Board Battens are used in building construction and various other fields as both structural and purely cosmetic elements. In the steel industry, battens may also be referred to as "top hats", in reference to the profile of the metal.

They are also used on tall ships to form the ladders up the shrouds in a fashion similar to ratlines. They are also used to help secure tarpaulinsover hatches, thus giving rise to the common phrase "batten down the hatches!

Used by analogy in non-sailing contexts, it means to prepare to weather a coming storm, whether that storm is metaphorical or real. Wood Working Hand Tools Classification of tools according to their use is given below Measuring and Marking Tools 2.

Holding and Supporting Tools 3. Cutting Tools 4. Planning Tools 5. Boring and Drilling Tools 6. Striking Tools 7. Miscellaneous Tools It consists of a steel Blade fitting into a wooden or metallic stock at right angle to it. The front edge is hardened so as to resist wear and tear.

It is made up of carbon steel. It is used for measuring and marking the points and lines on wooden stock before processing. Marking Gauge: It is used to draw parallel lines. The movable portion of the gauge is adjustable to suitable position and is tightened on the stem.

The piece which slides is called stock and scribing pin is fixed on the stem. Mortise Gauge: It is used to draw two parallel lines. Its working is similar to marking gauge except it has two sharp edges. One fixed and second adjustable or fixed Bar or T- Clamp and C-Clamp 4. Hand Screw 1. Four carpenter vice are fitted on opposite sides of bench to hold the jobs during operation.

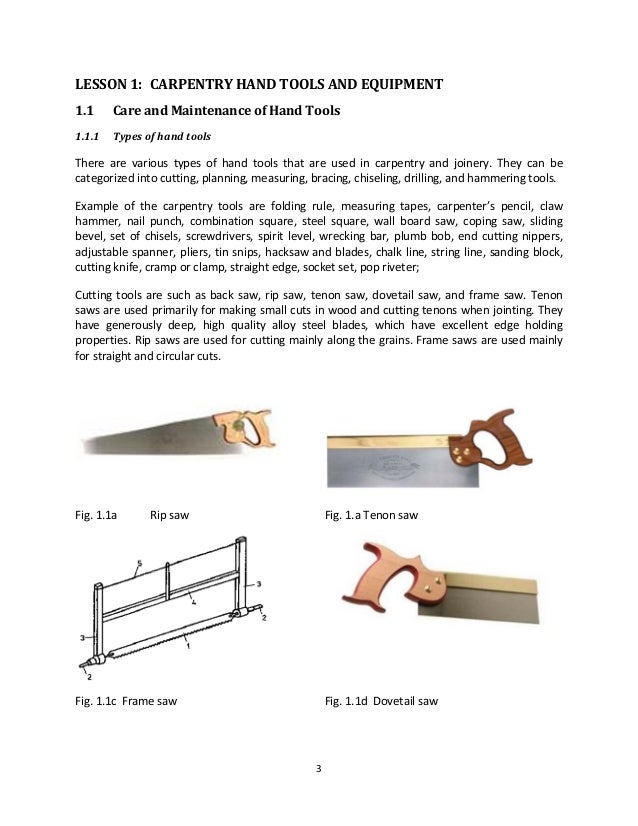

Its one jaw is fixed to the side of the table while the other is kept movable means of screw and handle. Clamps and screws: These are used by carpenters for holding and supporting wood pieces in position for carrying out different operations. Chisels 3. Axe 1. Saws:-Sawing means cutting woods along the grains. The main parts of a saw are blade and handle. The size of a saw is the length of the blade in mm. The teeth are bent slightly by its pitch and the angle.

Common type of Saws Rip saw 2. Cross-cut saw 3. Panel saw 4. Tenon saw or back saw 5. Dovetail saw 6. Compass or turning saw 7. Keyhole saw Dovetail saw 2. Compass or turning saw 3. Chisels:- In the wood work a large number of chisels are used for cutting the wood in different manners to produce desired shapes and verities.

Axes:- is a cutting tool made of carbon steel. The cutting edge is formed by beveling both sides of the axe. It is employed for splitting wood along the grains for rough work.

Planning Tools:- The planning tools are used for shaving or smoothing plane surfaces. A plane may be described as a chisel fastened to a metallic or wooden block called body. The Chisel fastened to the body at an angle of 25 to 35 degree respectively.

Another Blade called Cap Iron is used for stiffening the cutting blade, prevents chattering and helps in cutting and curling of shavings. The Cap iron should be 1. Wooden Jack Plane 2. Iron Jack Plane 3. Smoothing Plane 1. Boring and Drilling Tools:- for producing holes in wood. Gimlet Auger Bradwal Brace and Hand Drill Striking Tools Mallet 2.

Claw Hammer 3. Peen Hammer 1. Mallet Claw Hammer Peen Hammer Miscellaneous Tools 1. Screw Driver 2. Pincer 3. Rasp file Wood Working Processes 1. Mitre Joint 3. Mortise and Tenon Joint 4. Briddle Joint 5. Grooving and Tongueing 6. Dove- Tail Joint 7. Dovel Joint 1. They are quick and easy to make and provide reasonable strength through good long grain to long grain gluing surface.

The shoulders provide some resistance to racking diagonal distortion. They may be reinforced with dowels or mechanical fasteners to resist twisting. Applications Frame assembly in cabinet making Temporary framing Some applications in timber frame construction When the joint forms a corner, as in a rectangular frame, the joint is often called a corner lap. This is the most common form of end lap and is used most in framing. For a half lap in which the members are parallel, the joint may be known as a half lap splice.

This is a splice joint and is an alternative to scarfing when joining shorter members end to end. Both members in an end lap have one shoulder and one cheek each. Use for: Internal cabinet frames Visible frames when the frame members are to be shaped.

The two members are at right angles to each other and one member may terminate at the joint, or it may carry on beyond it. When one of the members terminates at the shin , it is often referred to as a Tee lap or middle lap.

In a cross lap where both members continue beyond the joint, each member has two shoulders and one cheek. For a Tee lap, one of the members has only one shoulder. Dove Tail Joint In its basic form it is both simple and strong. Although there are many joint variations, the basic mortise and tenon comprises two components: the mortise hole and the tenon. The tenon, formed on the end of a member generally referred to as a rail, is inserted into a square or rectangular hole cut into the corresponding member.

The tenon is cut to fit the mortise hole exactly and usually has shoulders that seat when the joint fully enters the mortise hole.

The joint may be glued, pinned, or wedged to lock it in place. We use your LinkedIn profile and activity data to personalize ads and to show you more relevant ads. You can change your ad preferences anytime. Upcoming SlideShare. Like this document? Why not share!

Embed Size px. Start on. Show related SlideShares at end. WordPress Shortcode. Subhasritam Behera , student Follow. Published in: Engineering. Full Name Comment goes here. Are you sure you want to Yes No. Sahil Khan. Sadhana Nam.

Sheikh Rafia. No Downloads. Views Total views. Actions Shares. No notes for slide. Page 1 of 7 Welcome to Fitting and Carpentry Shop 2. Students are required to come in proper dress while attending the Workshop practical class.

They should wear full shoes. Without full shoes no one will be permitted to enter into the shop. Students are required to come on time as per the timetable.

They shall be marked late if they do not turn up within five minutes of the scheduled time. Those who come late, are to take permission from Prof. No one will be allowed if they are late by 15 minutes in any case. Students are required to follow the instructions given by the teacher concerned or instructor strictly. They should remain present in their place of working for the whole class unless otherwise instructed.

Students are required to handle only those machines allowed to them by the instructors. Under no circumstances any student should handle machines not assigned to him.

Students are required to complete the job within the time allotted to them. They should give their attendance by signing on Workshop Card immediately after coming to the class.

At the end of the class, write down the activities done in the Workshop Card and get your grades before leaving. Students are required to do the job by themselves.

Instructors would only help them in difficulty. Students should gather as much information about the machine tools; power tools, hand tools, gauges, processes and other details as possible from the instructors. In case of any dispute, misunderstanding or difficulty, they may meet the Prof.

After each class, they are required to submit the record one bound volume for entire semester when they report for next class. On completion all classes in a shop, all students are required to submit the record, workshop card and all jobs made by them for evaluation. Each class shop record should consist of the following: i. Task to be done ii.

Raw materials used. Tools used iv. Description of tools and job holding devices with neat v. Procedure 3. Task a Introduction to fitting and carpentry section.

Record Submission a What is fitting and what are its applications?

|

Best 80s Rap Albums Editor Graco Finex Gravity Feed Hvlp Spray Gun Number Woodworking Plans For Garden Bench Questions |

10_SB_OO4

11.12.2020 at 19:22:32

KickBan

11.12.2020 at 23:53:20

21

11.12.2020 at 19:33:30