Build A Steam Box For Bending Wood Model,Cnc Wood Carving Machine Australia Driver,Boat Gel Coat Stain Removal Oil,Best Bench Players In Nba 2021 2020 - Plans Download

Curves such as those of the Standup Desk below add visual interest. And steam bending creates attractive curved parts. Every wood species, and even individual workpieces of the same species, can react differently to steam bending. Start with these best practices and then let experience be your guide. Keep notes on species, thickness, bend radius, and steaming time, and always bend at least one more part than you need.

When cooled, the lignin hardens, fixing the wood in the new shape. Steamed wood compresses considerably but stretches little. For tight bends less than 4" radiusa steel tension strap with attached end blocks applied to the outside of the bend minimizes stretching [ Drawing below ].

Mild bends, with minimal stretching along the outside, do not need strapping. Parts incorporating convex and concave curves in the same plane require a two-part form to sandwich the workpiece [ Drawing below ] or special tension-strap hardware [ Sources ]. Tension-strap hardware also is available to form parts with bends in two planes. For best results, use air-dried lumber, with dehumidification-dried lumber a second choice.

The heat of kiln drying makes lignin less susceptible to build a steam box for bending wood model by steaming. Use kiln-dried lumber only for gentle bends. All temperate-zone hardwoods chart below steam-bend well and, in general, bend better than softwoods.

Steam-bending other temperate-zone species is possible, but limit their use to gentle bends. Among tropical hardwoods, mahogany gives acceptable results. The brittleness of highly resinous tropical exotics make them unsuitable for bending. Regardless of the species you use, careful board selection increases chances of successful bends. Choose straight-grained lumber without knots or other defects and avoid decay even slight spalting.

The greater the run-off angle, the more likely the piece will break when bent. Splitting wood from a larger straight-grained billet guarantees straight, parallel grain but is not always practical. Straight stock runs through a planer or jointer easier than bent pieces, so do as much sawing, surfacing, or shaping as possible before bending.

Surface irregularities can cause splintering, so remove rough saw marks. Holes or mortises distort or they cause the part to collapse or split; perform these operations after bending. Leave extra length at both ends for trimming.

Where a bend is near the end of the part, extra length also provides the leverage needed to anchor the bend. Cut stock for parts requiring tight bends so the annual rings lay flatwise against the surface of the bending form [ Drawing delow ]. For build a steam box for bending wood model bends, grain orientation is less important. Steaming takes about one hour per inch of workpiece thickness and parts must stay on the bending form for one hour, so unless you make more than one form, the steam box only has to accommodate one part at a time.

For efficient use of the steam boiler [ Sources ], a steam box should be only large enough to hold the part blanks with room all around for good circulation.

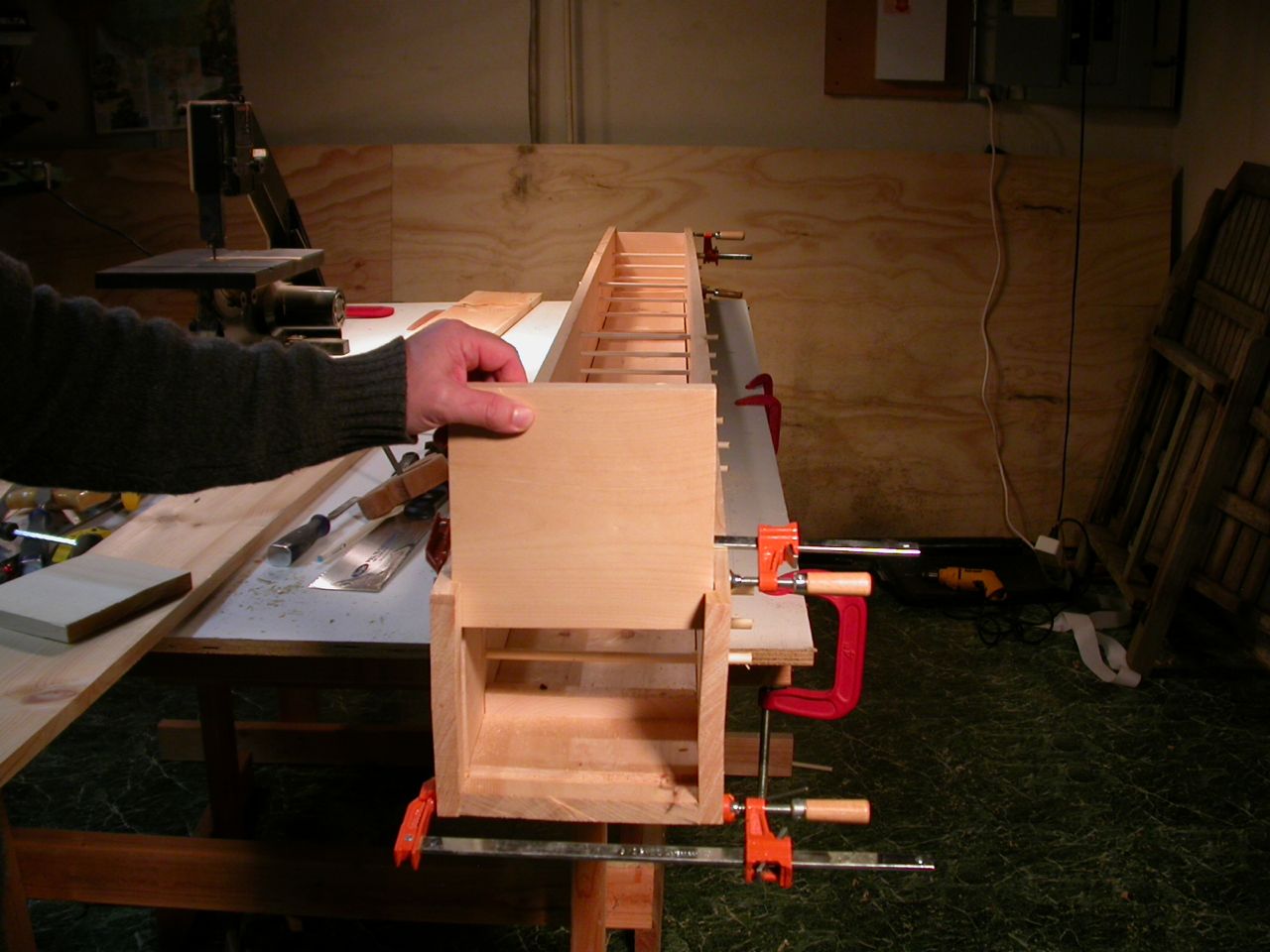

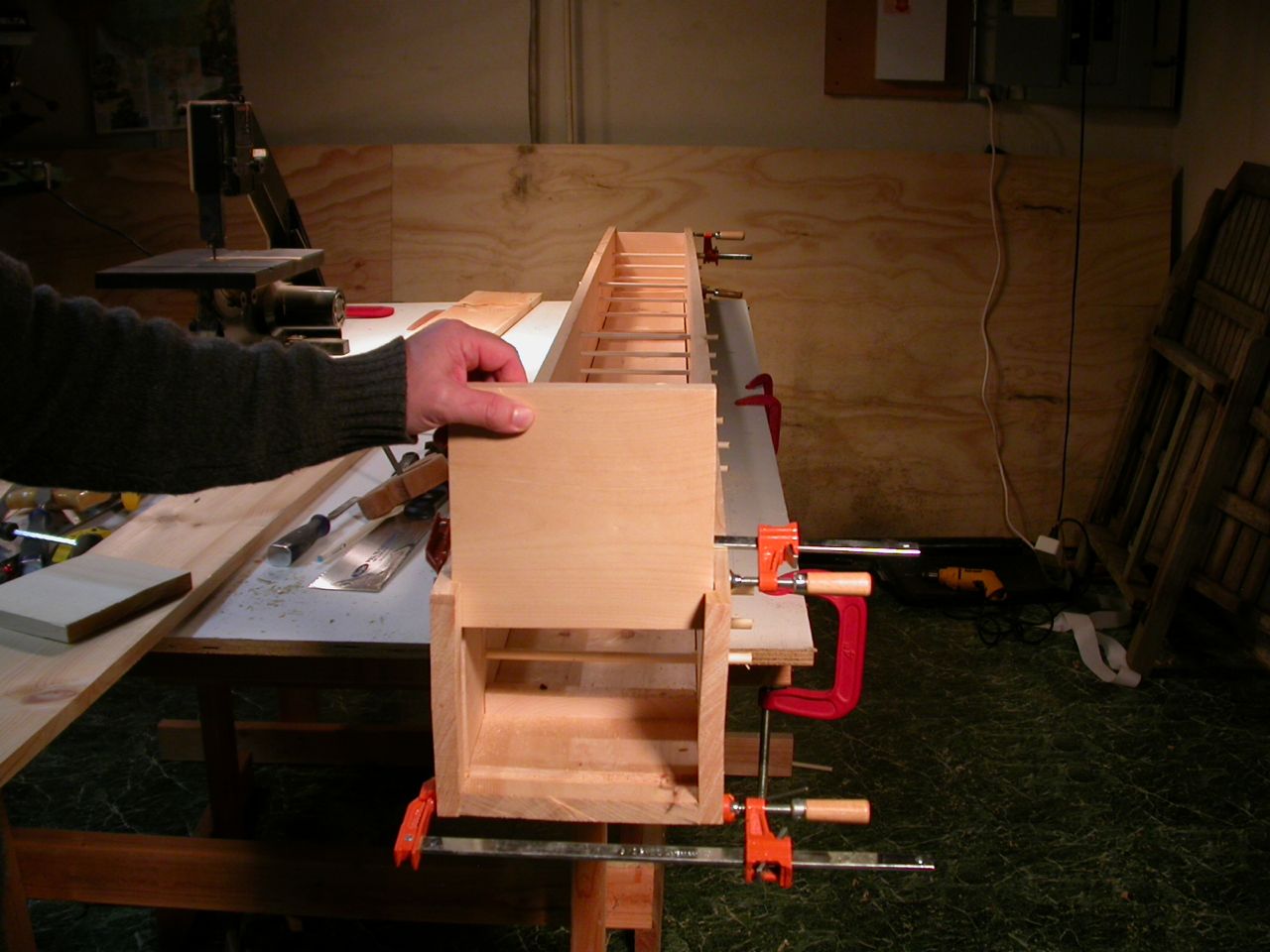

For tight bends on thick parts, increase box size to accommodate resteaming a partially bent piece. The steam box shown in [ Drawing below ] holds two leg blanks for the desk shown above and accommodates resteaming of a partially bent leg. Make bending forms from particleboard or plywood laminated to a thickness equal to the width of the bending blank.

Bending a workpiece puts considerable stress on the form, so when in doubt, more form width beats less every time. Bent parts retain most of their shape after cooling but to minimize springback, must be held to a form until completely dry.

The forms shown [ Drawing below ] are for the desk, shown in photo above. We made six drying forms to accommodate four leg blanks plus two extras. Securely clamp the bending form to a sturdy workbench. Have all clamps handy. Bending should be accomplished within build a steam box for bending wood model minutes after removing the blank from the steam box so you may want to rehearse your procedure.

Fire up the boiler. When steam steadily flows out of the drain hole, slide your blank into the steam box. Steam blanks for one hour per inch of thickness regardless of the width. Remove the part from the steam box and bend it [ Photos below ]. Working quickly, position the steamed blank between the anchor block and the end block on the tension strap assembly. Clamp the blank to the bending form and bending arm, applying clamps both vertically and horizontally. Begin to bend the blank around the form.

Thick parts, such as the build a steam box for bending wood model on the desk, require significant force so put your body into the bend or enlist a helper. Thick parts, build a steam box for bending wood model as the legs on the desk, require significant forcea so put your body into the bend or enlist a helper. Thick parts may not bend in one operation. When you feel too much resistance, remove the part from the form and re-steam it for 15 minutes. As the bend build a steam box for bending wood model completion, remove the bending arm clamps interfering with the bend.

Then draw the free end against the form with a one-handed bar clamp. Clamp the straight portion of the leg to the form and then add clamps along the curved section. Allow the part to cool for one hour and then quickly transfer it to a drying form. Clamp multiple thin strips at the bend to prevent surface splintering. Leave the part on the form for one week. Safety note! Steam scalds skin on contact. Opening the steam box releases a cloud of steam, so keep your face and any other bare skin away.

Wear heavy leather gloves when handling steamed blanks. Make sure the drain hole remains open. Do not pressurize the steam chamber: Pressurized steam is detrimental to successful wood bending and extremely dangerous. Source: Boiler: Steam-bending kit no. Sources: Spring steel strip. Tension-strap hardware for complex curves: S-bend unit no. Lee Valley Hardware,leevalley. Skip to main content. Steam Bending. Team up heat and moisture to add curves to projects.

Facebook Pinterest Twitter Text. Printer-friendly version. Read more about Wood Preparation. Not So Dangerous Curves Ahead.

Routing Ovals With an Ellipse Jig. Introduction To Cold-Bend Hardwood. Adding a riving knife to a zero-clearance insert. For more related content, subscribe to our newsletter! Keep small cutoffs from escaping at the bandsaw. Pegs provide positive grip on shop jigs. Head off scratches with a light polish.

Boom goes the accessibility! Tip of the Day. Turn your Workmate into a framing clamp. Build a steam box for bending wood model Subscribe Magazine Customer Service. Contact Us Advertise With Us. Facebook Twitter Youtube Pinterest Instagram.

|

Simple Small Wooden Box Plans Android Dewalt Flush Trim Router |

anonimka

06.02.2021 at 16:13:10

Bad_GIRL

06.02.2021 at 18:42:41

Aglayan_Gozler

06.02.2021 at 10:36:43