Watco Satin Wax 500,Resignation Letter Big 4 Online,Art Deco Hardware Drawer Pulls Effect - Review

Woodcare Systems. Beall Tools. Birchwood Casey. Georges Club House Wax. Giles and Kendal. Renaissance Wax. Rust Oleum. TMI Products. UC Coatings Corporation.

Show More. Featured New. Types Water Based. Water Soluble. Shellac Flakes. Finish Kit. Shellac Buttons. Wax Polish. Product Stain. Milk Paint. Universal Tints. Dye Stain. Powder Dye. Color Touchup Kit. Burn In Stick. Finish Restorer. Oil Finish. Flocking Undercoat. Grain Filler. Stain Blocker. Shellac Aerosol.

Wood Flour. Color Family Clear. Reddish Brown. Medium Brown. Brown Nutmeg. Dark Brown. Golden Oak. Light Brown. Medium Blue. Brown Mahogany. Honey Amber. Red Mahogany. Sheen Satin. Size Quart. Mini Half Pint. Set-Multiple Sizes. Ships From Woodcraft.

Woodcraft - Special Order. There is a certain amount of mystery revolving around oil finishes, with good reason. A good oil finish, while fairly easy to accomplish, is rare to find these days. It's a very low-tech process which, when done well, produces a magnificent finish, but it is a time consuming procedure which requires considerably more effort than simply brushing or spraying on a topcoat such as varnish or lacquer.

Primarily, an oil finish is IN the outer surface of the wood rather than ON the surface, which is the property that makes it such an attractive finish. Linseed oil is an oil extracted from flax, and the term 'boiled' is misleading but very important.

Boiled linseed oil is not actually boiled, but rather oxygenated, a process that changes the polymer structure of the oil, which causes it to eventually dry and harden. Raw linseed oil will never dry, and does not make a good finishing material.

Even boiled linseed oil dries quite slowly, and the addition of varnish or driers is common these days to speed drying and provide faster build of the finish. Tung oil is another commonly available finishing material, though more often than not, off-the-shelf tung oil finishes are not true tung oil at all, but rather a mixture of the materials I've previously mentioned.

Tung oil has become a somewhat generic term, encompassing many varieties of oil finishes. My favorite oil finish is Watco TM Danish oil finish, the ingredients of which are a closely guarded secret -- it's safe to say, however, that it is also a mixture of oil, varnish, thinner and driers.

It's my favorite for the simple reason that it's been around for many, many years, and the manufacturers have in general been quite obstinate about not meddling with the recipe for the stuff, which makes it far more predictable than most finishes.

After several years of working with Watco and other oil finishes, it became quite apparent to me that the manufacturers were more interested in promoting and marketing these products with the focus upon 'quick and easy finishing' as opposed to helping the user achieve striking results. An old finishers' adage concerning the application schedule for oil finishes went as follows:.

Well, that's a lot of work, and most people are not interested in maintaining this schedule, nor are most furnituremakers delighted at the prospect of having a piece in the finishing process for three months or more before it can safely be delivered to the client. Many manufacturers of oil finishes have addressed this problem by advertising their products as a 'wipe-on, wipe-off' finish, leading the user to believe that a simple one or two-step application is all that's required In fact, the next time you find yourself in the wood finishing section of your local paint, hardware, or home center and see any finish product that boldly proclaims that you can now have a beautiful hand-rubbed finish in 2 hours, you have my blessing and my gratitude if you just smirk and walk away.

Fortunately, the correct process to achieve a gorgeous, truly hand-rubbed oil finish lies somewhere between the two extremes. Try this procedure once, and you'll probably never be able to see one of those 2-hour products again without laughing out loud. If you really want to spite the manufacturers, a common recipe for home-brewed oil finish is to mix equal parts of boiled linseed oil, turpentine or mineral spirits, and plain oil-based gloss, not satin varnish or spar varnish spar includes some UV inhibitors.

The finishing procedure is the same. Poorly done oil finishing, which we see a lot of, accomplishes the first objective, but not the other two, leaving a finished piece that is fairly well sealed, but entirely lackluster and uninspiring. In my opinion, this is what you end up with most of the time by following the manufacturers' instructions.

So I re-wrote the instructions. Specifically, I re-wrote the instructions for Watco Danish Oil finish, because it's the product I personally use most often, but other oil finishes are very similar, and the method works well with tung oils and other oil finishes. Drying times are approximate, and at least in my shops, Watco dries more slowly than the container's instructions would lead you to believe. It's not imperative, but it is desirable that previously applied coatings be thoroughly dry before moving on to the next step, which in my environment generally takes anywhere from 1 to 3 days.

Note that any rags and cloths you use are very susceptible to spontaneous combustion. This can occur when the solvents attempt to evaporate from your rags but do not have sufficient air to evaporate into. I won't make any recommendation concerning what you should do with your finishing cloths, nor will I take any responsibility should your shop catch fire. Watco and other manufacturers recommend submerging used cloths in water to prevent spontaneous combustion, and this is certainly the most foolproof method.

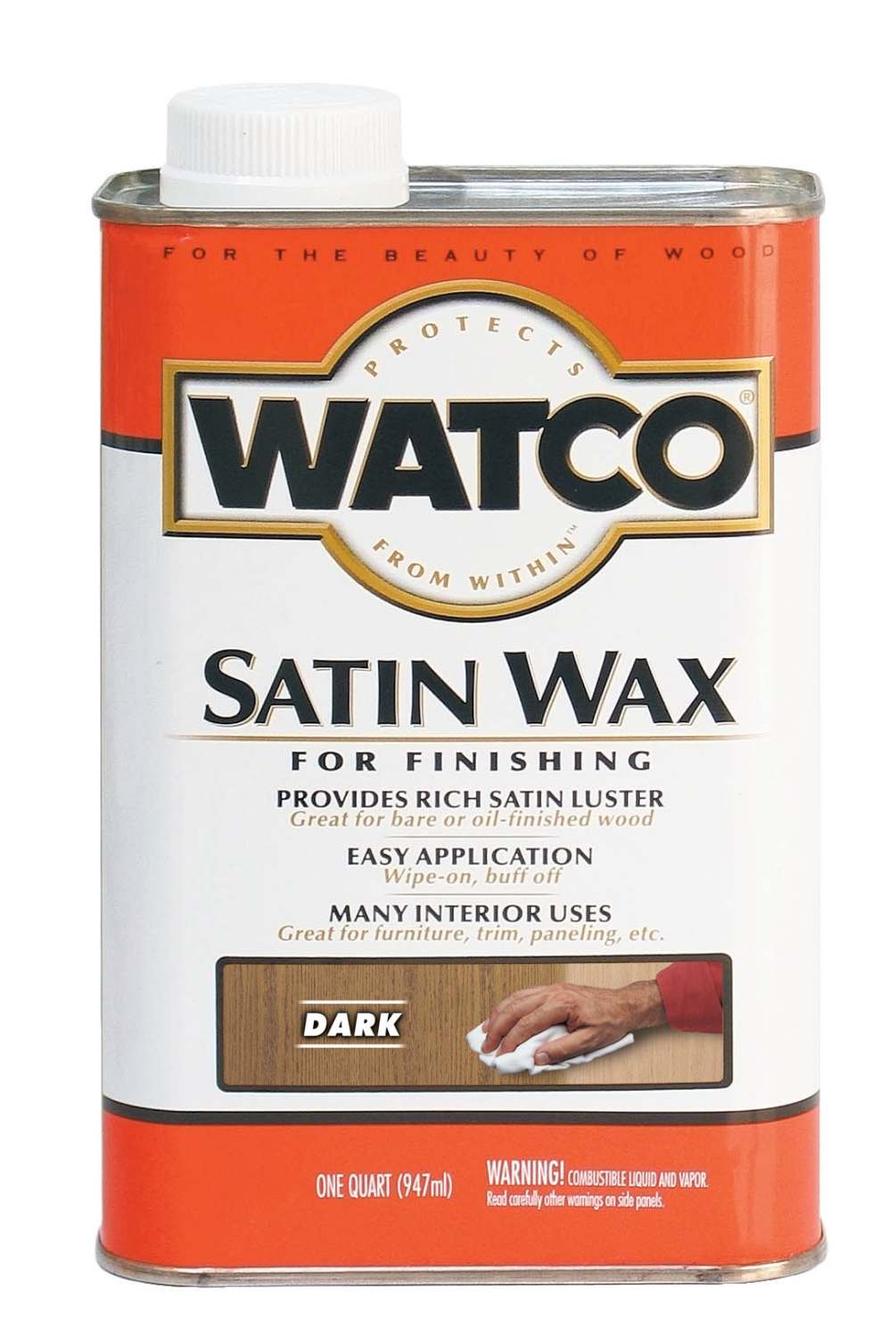

My own method is to take my rag s and drape it somewhere near my work piece where it will get plenty of air circulation, and allow it to dry there. That way I can tell how dry the finish on the wood is by checking to see how stiff the rag is. Also note that I recommend Watco Satin Wax in the final steps of the finishing procedure.

This is a liquid wax which allows you to wet-sand the first wax coat , and as of this writing, is available in either natural white or dark walnut.

|

Best Rap Features Of 2020 10 Mini Wood Turning Lathe Garden Wood Carving Machine In India War |

Dusty

09.11.2020 at 23:11:38

ZARINA

09.11.2020 at 10:12:33

Lerka

09.11.2020 at 12:42:56