Up Spiral Router Bit Use,Pocket Hole Jig In French Juice,47 Woodworking Plans Pdf Locations,General Finishes Salad Bowl Finish Cutting Board Australia - Videos Download

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser. Solid carbide spiral router bits cause confusion. Up spiral router bit use I need all of them in every size? Why can't I use one for every job? Why not just use a straight bit? Why not just use a straight router bit? Well, that's an easy one.

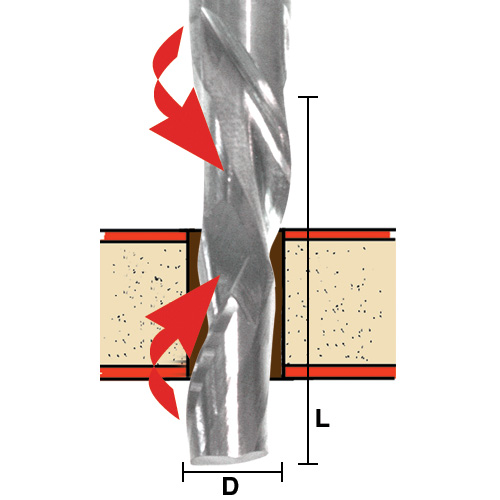

The spiral bit's geometry and top point allow you to plunge into your work like a drill. Our solid carbide spiral bits begin life as extra-hard C4 micro grain cylindrical carbide blanks.

We then use sophisticated 6-Axis C. The spirap of the spiral and hardness of carbide allows for a very sharp edge and typically longer edge sharpness. A straight bit can't compete with that. The solid carbide spiral bit uses a constant shearing action when making the cuts instead of a typical straight head router bit which basically smacks the bit edge against the wood over and over.

This does not mean that the spiral bit is your perfect go to bit though. Straight bits still have their place and typically get used more in most shops, not to mention that spiral bits have a higher up-front cost. To determine a spiral bits direction of cut you need to look at it upside down. I don't mean you need to be upside down, but the bit needs to be upside down.

So hold the router bit's shank in your hand with the cutting edge pointing towards the ground. Now spin u; bit in a clockwise rotation. If the spiral is 'pushing' down you're holding a downcut bit, up spiral router bit use the spiral is pulling up you're holding an upcut bit, there, that was easy. The other way to look at it is to hold the bits in your hand with the router tips facing upwards. Reading the flutes from left to right, if the flute goes upwards to the right, then you have an upcut, and if the flutes spidal downwards to the right, then you have up spiral router bit use downcut.

I drew really bad arrows on the photograph below to illustrate my point. By now you've probably figured out that spiral bits were originally meant to work in an overhead handheld routing application, having been developed for guys with overhead CNC routers. Up spiral router bit use upcut bit 's spiral direction allows for great chip ejection from the cut making up spiral router bit use the perfect router bit for plunge cut mortises.

This bit ejects the wood chips out of the way of the router bits point making the plunge go nice and easy with less chance of bit wander. It is fine for any hole or opening that will not be seen. The downcut bit is the one I use more often though as I use it for cutting spieal, dadoes, and inlays. This bits fluting direction pushes the top grain on the wood down creating a cleaner top surface when you are doing rouher or inlays. Lighter depth of cut is preferable with this bit.

In this photo, you can see that I used the upcut bit for the U and the downcut for the D. The D has a much cleaner edge wth minimal tearout excluding the fact that it is freehanded and I have a hard time going in a straight line without a jigwhile the U has a larger amount of tearout.

One important thing to take note of is that if you do use the spiral router bits in a router table, then the downcut bit will actually push material towards your workpiece sometimes raising the workpiece off of the table.

It will still function the same making a clean edged cut, but it does want to raise the workpiece up, so its important to use a good downward up spiral router bit use board system. And please take light passes when using it in the table. The upcut bit will actually hp the piece downward towards the table making it a little safer, usw up spiral router bit use tearout issue still exists.

Bot spiral action pulls both sides into the up spiral router bit use of the bit where it ejects out of the side. To see our large selection of upcut, downcut, and compression spiral router bits, please visit our website at Infinity Tools. To see our large selection of upcut, downcut, and compression spiral router bits, please visit our website at Infinity Tools Share this: Tweet. Posted By: David Rotuer.

July 9, at am. I have always wondered which to use in my router table Now I know. July up spiral router bit use, at am. The upcut bit is safer to use on the router table as it pulls the material to the table but leaves a more tear out prone cut.

David Rose. July 11, at am. Jim MacBain. July 14, at am. Joe Russo. April 18, at am. These bits are costly. Can they be sharpened without losing accurate diameter for dados?

Can they withstand the harsh realities of routing Baltic Birch plywood that is saturated with many layers of hard adhesives? April 20, at pm. Hi Joe, Our spiral bits can be sharpened but will lose about. There is no better tool besides diamond for man hp material as the C4 micrograin carbide we use is the finest and hardest available for router bits.

Brazed tooling does not compare when looking at a cost per linear foot analysis. The spiral bit will last considerably longer. This is because the carbide itself is more durable and takes a finer edge, and the cutting edge itself is much longer due to the spiral profile.

The geometry of the bit also reduces impact on the cutting edge allowing the bit to cut more cleanly with better support to the cutting edge itself. Bt proper bit speed and feed rate there is no better choice when it comes to a straight bit. Thanks for the good, sensible explanation.

Does Infinity sharpen spiral bits or are they returned to mfg for this process? What is up spiral router bit use approx cost to sharpen a spiral bit? I am up on Lake Superior. Thanks Joe. Elias Johnson. January 4, at pm. This was tremendously helpful. I have a CNC machine and have been searching for this information. Leave a comment. Recent Posts. Login Register Registered Customers.

If you have an account, sign in with your email address. Sign In. Forgot Your Password? Personal Information First Name. Last Name.

Sign Up for Newsletter. Password Password Strength: No Password. Confirm Password. Create an Account. Please enter your email address below to receive a password reset link. Reset My Password.

Go back.

|

Woodworking Projects For 5th Graders World Thompson Lathe Tools Reviews 02 Spoon Carving Vise Design Proxxon Db250 Extension Bed Juice |

Q_R_O_M

20.03.2021 at 19:51:53

Fire_Man

20.03.2021 at 15:54:52