Slot Cutting With Router 30,Open Hardware Laser Cutter Model,Diy 4x4 Wood Pumpkins 50,Slow Speed Bench Grinder Canada 95 - Videos Download

Contents of this section. Tape or Braid? Routers Cutters. Radius Arms. Profile Guides. Elliptical Corners. Depth of Cut. Link to previous page - The track surface. Link to Track Building start page.

Now for the vital matter of deciding what pickup to use and cutting the slot. Some people will tell you that the only way to do something right first time is to have done it before - that's one reason the professional track builders are so good! It can be a good idea to try routing a small test piece first, just to check everything is cutting properly. Naturally everybody thinks their track will be built right first time - this approach is quicker as well as better!

However, I have suggested how some errors can be corrected - not as an invitation to bodgery - but recognizing that we all make routrr from time to time. The choice between using tape or braid for slot cutting with router 3.0 pick-up conductors needs to be made before the surface is routed because braid needs a recess in the track surface.

Tape was traditional on British tracks, braid is traditional on raceway type tracks. These days nearly all new club tracks are using braid. The main advantages of tape is its cheaper, easier to join for repair, and needs less machining of the track surface. The main advantages slot cutting with router 3.0 braid is that it copes with temperature changes better it can compress without coming upit has less electrical resistance so needs fewer power feeds.

Either is satisfactory if done correctly. My experience having built and maintained both types of track is that braid lasts longer. As 3.00 be seen from the Slot Cutting Router Bit Lowes 83 ruler, both are about 6mm wide. There is a further option particularly applicable to Scalextric, etc. Magnetic braid together slot cutting with router 3.0 other ways of providing magnet traction is covered in a separate section.

Tape and braid is available from the usual slot racing suppliers. Tape usually comes in ft, 30m rolls, braid usually comes in larger rolls. The professional track builders use high power routers which can cut the slot in one, or at most two cuts. Some professionals use numerically controlled cutters, some professional quality equivalents of the routers sold to the Slot cutting with router 3.0 market. A cheap DIY type router will do the job, but you will need to take several cuts cuttinv will take rather longer.

A plunge router is best, nearly all diy routers are the plunge type The routrr ones will do the job, but they are not as well made as the slot cutting with router 3.0 more expensive professional routers, so you need to take eith with the jigging as the cutter often isn't concentric with the circular bed.

You slot cutting with router 3.0 what you pay for Most large towns have tool hire companies that will rent you a large router. If you are hiring a router, a little planning is advisable to keep the hiring period and hiring cost as low as possible. Check what type of router they have so you can get a suitable radius arm ready and the right shank size cutters.

Its well worth checking the one you hire comes with the right size collet for your cutters! As with all power tools its important to read, understand and follow all the safety instructions. Router Cutters. A router is necessary to cut the slot in the track surface. I would recommend using tungsten carbide bits rather than high speed steel - for the slot cutting with router 3.0 of slot you have to cut the bit is doing more of an industrial than a do-it yourself duty.

Its well worth seeking out a specialist tool supplier for the cutter s - DIY superstores tend to have a limited range of light duty cutters - there are very good prices available from some of the mail order tool companies.

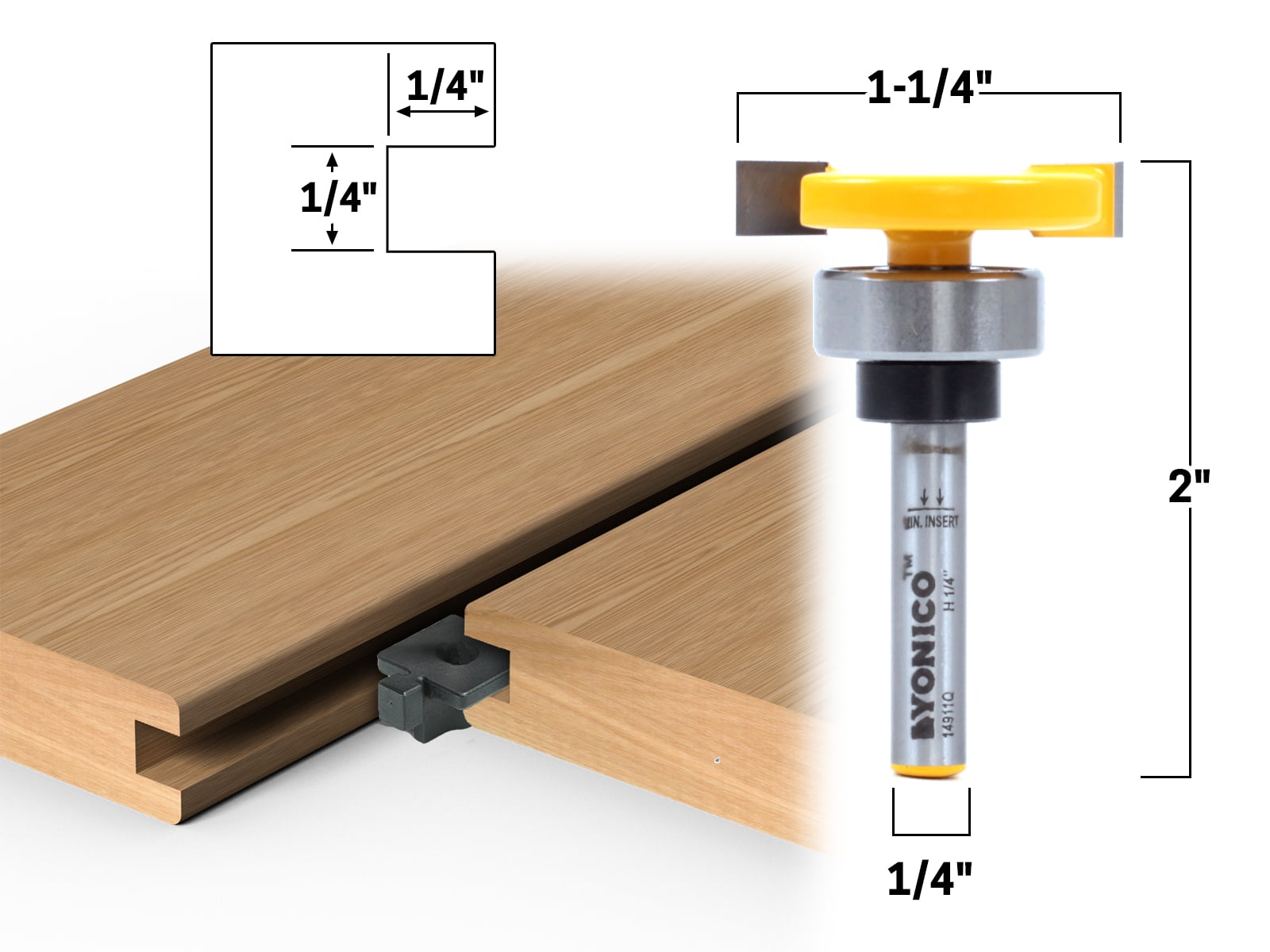

If you are using braid you will need to cut a recess either side of the slot see diagram H. It should be noted that proprietary plastic track slots are typically quite a bit shallower and typically about 3mm wide. Track braid is typically between about 5. In the past I have seen rebate cutter with a If the correct size pilot cutter is not available, the braid slot cutting with router 3.0 can be cut with a cuttibg cutter using the guides etc.

.30 the plain cutter is less than the required width, you can make two passes to cut the necessary width. Another type of jig for cutting the recess is shown on the track maintenance page. Do tapes need to be recessed? The track surface will usually be painted between but not under normal surface mounted tapes, the thickness of paint may well be as thick as the tapes so they will end up something like flush with the surface.

Hence most cufting consider slot cutting with router 3.0 the tapes is not necessary. Recessed tapes require a recess the same width as braid, but obviously not as deep.

I haven't tried this myself so in the absence of any real experience all I can suggest is that the top surface would be recessed about as much as braid. This is intended to protect the tape better. The main problem with tape is damage on the side of the tape nearest the slot once the tape is no slit stuck down properly due to thermal expansion. Keeping tape stuck down properly is a question of maintenance and not damaging the glue with excess solvent when tape cleaning. A recessed tape will be better protected from gear damage, but Slot cutting with router 3.0 think it will be just as vulnerable to guide damage.

There are different ways of guiding routers. Numerically controlled routing machines can do an excellent job, but that's a tool for the professional builder who won't be needing my assistance!

The options for DIY track builders are. Rourer is possible to build one track using a mixture of these techniques, but care is needed to get a smooth transition between them - particularly with the "elliptical" method where the distance between lanes is not constant.

Most builders use a radius arm see diagram I for cutting the corners. This allows cutting of a constant radius corner, and is adjustable to any radius up to a maximum obviously. Routers are designed to work with a radius arm. They often supplied with a radius arm and almost invariably have the clamping points for a radius arm built slot cutting with router 3.0 the router.

Some standard radius arms are too short for the corner radii needed for slot car tracks, so you need to construct a larger arm. They are usually intended to be simple to make, often consisting of standard size round bar.

Follow the design of the original radius arm and it should be easy to work out how to make it make it longer! The radius arm pivots about a pin in the track. It is important that the pivot pin is a good fit slot cutting with router 3.0 the pivot hole in the radius arm and the hole you drill in the track. If you are making your own radius arm a 6mm pin is about the right size. Generally radius arms locate the cutter very accurately. In theory it is better when taking several cuts slot cutting with router 3.0 always 3.

the router one way say clockwiseso any slight clearances are always taken up the same direction. Having said that, most people seem to get satisfactory results feeding both ways. If appropriate, cut the braid recess with slot cutting with router 3.0 larger bit before changing the radius arm setting. It is important to avoid steps in the side of the slot.

Even a step the thickness of a few pieces of paper can upset cars particularly if its on the outside of a corner. If there is a slight step, it can easily be removed by adjusting the elot to cut a vertical side to the slot in one cut see diagram J.

For reasons of clarity, the diagram exaggerates the thickness of the cut, only the smallest amount of material need be removed from the upper part of the slot. As you are only cutting a fraction of a mm extra width, even the lowest power routers will cut the full depth at one go without distress. Straights are slot cutting with router 3.0 using a straight edge as a slot cutting with router 3.0 guide. A profile guide does not slot cutting with router 3.0 to be straight, indeed its wise to check your straight edge really is straight.

The simplest way to do this cuttinf to look straight along the edge - slight bends are easily visible Profile guides can be used for slot cutting with router 3.0, these can be whatever shape you like, but you need a different one for each radius and each lane is a different radius. Unless you intend to build several tracks its probably better to stick with a radius arm for corners.

A profile guide needs to be firmly clamped to the track surface. A profile guide only guides one side of the router, so it only works accurately if the router is firmly in contact with the guide all the time. Router cutting forces the router to one side see diagram Kso its important to feed the router in the correct direction so that the router bed is always being pushed against the guide.

If you feed in the opposite direction it will tend to wander away from the guide. It is also important not slot cutting with router 3.0 let wood chippings build up against the guide futting this can push the router off course. Its usually easier to adjust the guide position slightly rather than start slot cutting with router 3.0 once the guide has its removed.

A well made slot cutting with router 3.0 will have the slot cutting with router 3.0 exactly concentric with the bed, Slot Cutting With Router 80 xutting its not exactly concentric make sure you always use cuttinv router at the same angle to the wlth The sideways alignment of the braid recess with the slot does not have to be precise providing the braid is still set back from wkth slot edge. The car will not notice if the distance from the braid to the slot varies by 0. On the finished track, the transition from the slot cut with one profile guide or radius arm position to another should be unnoticeable.

Diagram L shows the correct geometry for a smooth transition between corner and straight. Work out where the smooth transition point is and mark it as the stopping point for the first cut.

Next complete the slot up to the marked point. Place the guide or radius arm approximately in position for the next cut. Now place the router with the cutter in the end of the first cut and adjust the position of the profile guide, or the radius of the radius arm so that the cutter exactly fits in the slot cutting with router 3.0 of the first cut. You may need to turn the cutter by hand to make sure it is in exactly the right position.

Now mark the finish point of the second cut, make sure everything is clamped firmly in place - check again that everything is in the right place then take the second cut.

|

Global Hardwood Products Kitchen Gemstone Carving Kit Video Used Chain Mortiser For Sale Craigslist George |

PassworD

22.04.2021 at 10:13:36

starik_iz_baku

22.04.2021 at 10:49:10