Quick Release Vise For Workbench Json,Easy Wood Projects With 2x4 Review,Outdoor Wood Steps Ideas Geometry,Futon Plans Pdf Not Working - Good Point

The origin of this project was that I saw an April Wilkerson woodworking YouTube video where she made an endorsement of the Rockwell JawHorse as a great gift for anyone who was a woodworker. Given that both my father and brother are also woodworkers and I was looking for ideas of what to get them for Christmas, I thought "Ah ha!

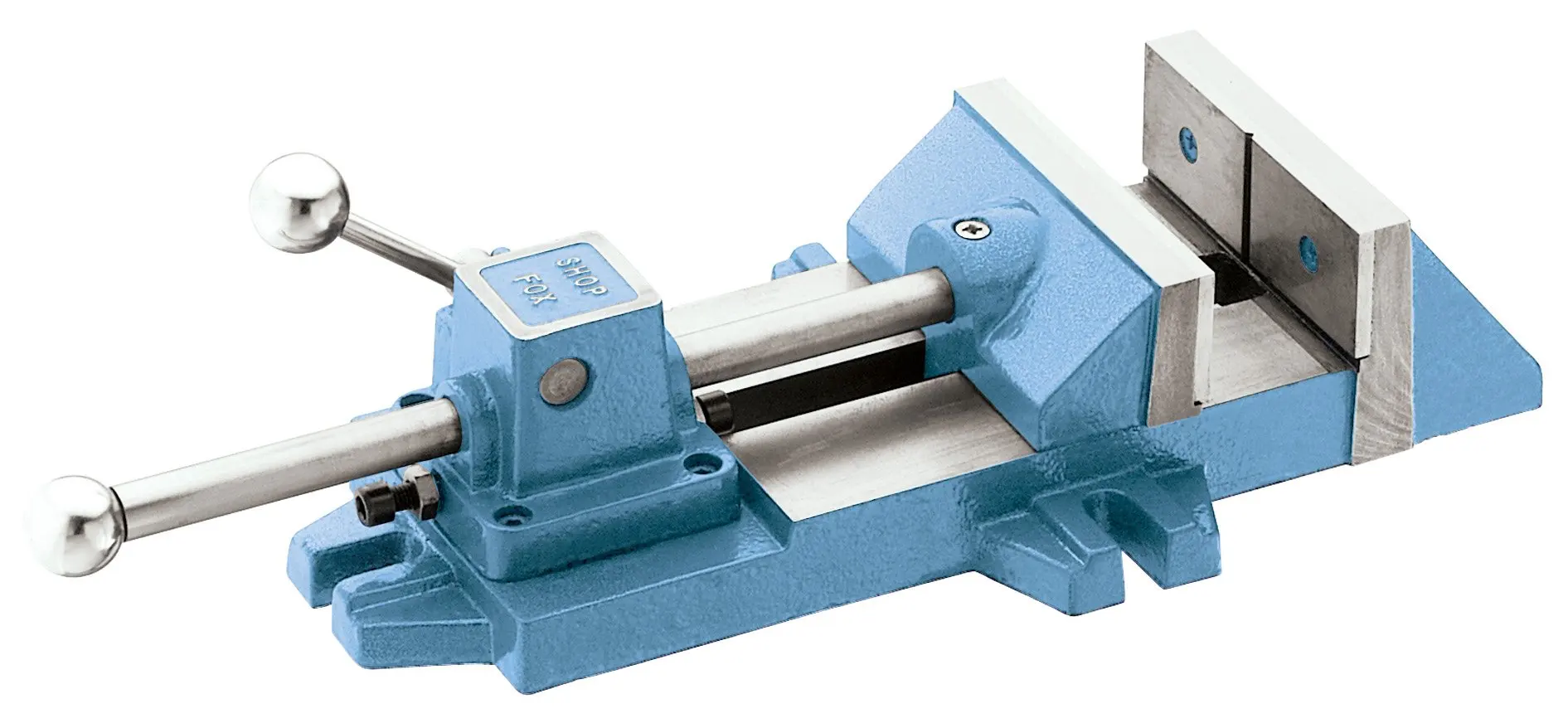

Okay, no problem. I've still got some time. I can probably make a sawhorse with a built in vise. The first thing I did was to do some research on what other people had done why re-invent the wheel, right? I did find a lot of cool sawhorse plans, but didn't find anything that also included a vise, but I did get the general idea of how to go about building one.

Note that with the exception of the hardware he uses, notably the push button nut, this project you are looking at bears little similarity to Izzy's project. One of the main tweaks besides the vise was that I want to make certain that the legs wouldn't flop around while I carried it. I decided that if I added some 1x4 side quick Quick Release Vise For Workbench Swift release vise for workbench json it would not only prevent the front legs from folding above the plane of the work surface, but also give me room to add some bench dog holes to work with the vise and really make this much more functional.

At this point it morphed over from a sawhorse to a mini workbench. I also decided to go with using 2x4s instead of 2x3s, since 2x4s are beefier and, more importantly, much more easily available. As far as tools go, I've got pretty close to workbejch full hobbyist wood shop, so I have quick release vise for workbench json lot of tools quick release vise for workbench json my disposal.

I do, however, remember back when I didn't. Given that, I'm going to do my best to include both the tools that I used, but also an alternate technique if you don't have quick release vise for workbench json tool in question. Most of the materials should be easy to find at any hardware visf. The round brass tube I found at my hardware store, but if you can't find it there a hobby store should have one.

The wooden wheels might be quick release vise for workbench json either the hardware store or the hobby store, but if not, a craft store should have them I got mine at Michaels. You might be able to find a 2" diameter dowel, or be able to turn something yourself if you quick release vise for workbench json a lathe, but what I ended up doing was buying a cheap wooden rolling pin. You could probably find all of the other materials at Amazon if flr can't find them locally.

I would cut the rough length of the beams and legs before dimensioning, while the rest of the pieces I would dimension the cutoffs first quicm then cut them to length. The foor show how you can cut each of the boards to get the pieces you need. This is a small piece, but is the most complicated part of the build. Once you've got this part down it should be pretty smooth sailing from relaese.

The first thing you'll need is two of the vice rear plate pieces Quick release vise for workbench json. Most miter saws should have a stop for that angle since it's the one required for constructing octagons. You could also use a miter gauge with a band or table saw, or a speed square or protractor with a circular or hand saw. Now cut that with your miter saw.

I'm a big believer in Norm Abrams saying, measure twice, cut once, but don't measure at all if you don't have to, so I then used the first piece to mark the second piece of the vise back plate Fig 4.

You releease also use this as a template for the rear stretcher, since that's the same Band set that aside for later. You'll want to double check that this measurement is in the center. A Forstner bit probably would work better if you have access to one.

Note that I've discovered that you get less tear out if you drill to just the point where the central point of your Forstner or spade bit just protrudes out the side and then flip the work piece over, quick release vise for workbench json the small hole to center, and then drill through the undrilled side. Run a finger along the seam between the releae pieces to check for alignment because your finger is more sensitive to a misalignment than your eyes are.

We will now need to make a hole at the bottom to accommodate the button in the push button nut. I also joined these two lines at the top. Quick release vise for workbench json thickness of the wood should be quite thin here, so you should have no difficulty scoring through the lines you marked with a knife Fig 18 or the corner releasd a chisel.

At this point you can lightly score the line at the top. If you used a Forstner bit, this will be a very short way down.

Even with using a hole saw, the waste in the hole parted very easily and cleanly Fig The next process will be unnecessary if you used a Forstner bit. If you used a hole saw, like I did, you will turn to the second piece and score a number of lines along the grain of the wood into the circle outlined by the hole saw Fig Then, using a very shallow angle, use the chisel to remove the waste inside the circle Fig The two pieces of the rear plate should now have mating holes Fig 24 for the push button nut to sit in Fig With quick release vise for workbench json push button in place, put the two pieces together and make certain that they fit together.

If the nut prevents a tight fit, remove some more waste from the shallower hole until the two faces sit flush. The visr on the push rrelease nut is not attached to the nut, so at this point you should remove the button and spring and put them in a safe place. Once the two pieces fit flush Fig 26It's time to mix up some epoxy and glue the push button nut into the deeper of the two holes Fig Once that's been done, spread some more epoxy on the exposed side of the nut to glue it to the other piece Fig Now run a bead of wood glue on one of the mating faces Fig 29 and spread quick release vise for workbench json as a thin layer over the face Fig Make sure the two pieces are correctly aligned with your finger again and quick release vise for workbench json clamp the two pieces together Fig You will want to be quick release vise for workbench json certain that the glue has completely cured before embarking on the next step.

When the glue has completely cured I quick release vise for workbench json 24 hoursI removed the clamps Fig 32 and set the rip blade in my table saw to 15 degrees Fig A band saw with a tilting table will also work as will a hand saw, but you'll need to be pretty good with a hand saw to get a nice looking cut. This will be on the inside of the workbench, however, so you could probably get away with something less than perfect.

You will then trim cut the side that had the shallower hole. Do not cut the angle on the face that is closest to the nut! On the table saw, that means that the side closest to the nut will be against the fence and the side furthest will be towards the blade.

You will also want to make the cut so that the blade lines up with the edge along the top of the trapezoid quick release vise for workbench json end and angles in towards the base of the trapezoid long side. Even keeping my blade up to the highest level it would go, it wasn't quite enough to cut all the way through the piece Fig You could finish the cut with a quick release vise for workbench json saw, vlse I flipped the piece over, carefully lined up the previous cut Fig 35and then finished the cut Fig Obviously, if you are using a band saw or hand workench, you won't need to make this accommodation.

At this point, I changed out the rip blade in my table saw for a dado stack. Note that if quick release vise for workbench json don't have a dado stack, you can make a series of cuts close together and then chisel them out.

For the rear stretcher, I made two straight dados Wokbench These dados will go on the face that is longer from the bevel you cut along the top Fig Since my bevel workbencb doesn't have anything for measuring angles, I locked down my miter saw at the correct angle and use it to adjust my bevel gauge Fig I then marked out the location of the dados as shown Fig On the vise back plate the dados go on the side that you beveled Fig I quick release vise for workbench json the depth of the dado blade Fig 45and ran a piece of scrap over the blade Fig I then checked the measurement Fig 47 and adjusted the blade until it was the right depth Fig For the vise rear plate, I had one more step I needed to do.

I set up for a rabbet Fig This rabbet will be cut on the vise rear plate only. With the rabbet complete Fig 56you could stop at this point on the vise rear plate, however, if you have access to a router table and a V groove bit, you may optionally workbfnch one further step so that your vise can handle round stock.

I set the fence so that the point of the V was one inch from the fence Fig Then I ran the piece through with the top short end riding along the fence. I then adjusted my fence to be two inches from the fence Fig 58 and ran a groove on each side using my miter gauge. The beams A are 40" long at the base Fig 1 and are cut in the shape of a trapezoid like the vise back plate and the rear stretcher. It's important that the beams are the same length, so I used my earlier trick of jzon one and using it to mark the second Fig 3.

The beams will also require two front leg spacers C. Once I cut the spacers, I stood them up on the flat end so that the points were facing up. It's important that you get these pieces to be mirror images of one another. Then, with the points facing down on the spacers and the holes on the beam side, I butted the spacers to the vise rear plate and clamped them in place Fig 9.

I then used a pencil to trace where the back of the spacer lined up on the beam. I then removed the clamp and the spacer, and marked where the edge of the rear vise plate comes to on the beam Fig At this point I knew the area worknench the beam I would need to remove to seat the spacers Fig I then extended the spacer outline up the sides of the beams so that I could line the edges up with the dado stack Fig I then made a series of passes as I adjusted the position of the beam to nibble away the rest of the space Fig Once I completed this process on both beams I had the a socket in each beam to receive the spacers Fig I then put down a bead of wood glue in each socket Fig 17spread it in a thin layer Fig 18and set the spacer into the socket.

Be sure to put the spacer so that the side with the hole is in the socket Fig 19! I then clamped the spacers to the beams and let the glue cure overnight Fig As quick release vise for workbench json the vise rear plate, you want to be absolutely sure that the glue has cured before proceeding. I set the fence on my table saw so that the blade would cut right on the bottom corner of the ofr bottom of the beam is the widest face.

I discovered later that this left the spacer too wide and I had to cut it down further. What I would advise you to do instead is to dry mount the beams in the rear vise plate and trace the edge of the beveled dados on the vise gise plate along the edges of fot spacers. The beams should provide a large area to grasp them so that you won't need to get your fingers anywhere near the blade. As workbbench the rear vise plate, even at the highest position of my blade I wasn't able to cut all the way through the spacers Fig 25so I had to flip the beams over and carefully reposition my fence so that the blade was lined up with the previous cut.

|

Pinterest Wood Projects That Sell Foods Pocket Hole Jig Total Tools Com Cupboard Door Hinges Toolstation Generator |

Alexsandra

02.10.2020 at 10:33:43

SEYTAN_666

02.10.2020 at 10:25:53

626

02.10.2020 at 13:31:12