Leveling Radial Arm Saw Table 3d,Wood Workshop Insurance Quote,Shank Router Collet Mac - Try Out

Nearly all radial arm saws are designed with a metal sae to which a replaceable wooden Leveling Radial Arm Saw Table 60 surface can be affixed. While there are other stationary saws that also use replaceable table surfaces, the design of the radial arm saw is such that the table surface leveling radial arm saw table 3d to be replaced more often. The radial arm features a raised motor and saw blade which cuts stock from above. This means that the saw blade cuts aem down into the tabletop on virtually every cut, and over time the table surface becomes filled with grooves from the blade.

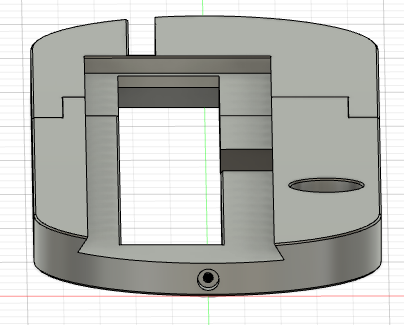

The saw is engineered in a way that makes it leveling radial arm saw table 3d to replace this tabletop when it becomes badly marred. If you look closely at the tabletop of a radial arm saw, you will see that it is constructed of three pieces: a large open expanse of tabletop which supports the stock as you cut tablle a small vertical fence set just behind the main tabletop; and a narrower section of tabletop that abuts the back of the fence, essentially sandwiching the fence between the two horizontal segments of tabletop.

The bolts that secure the tabletop to the leve,ing table of the saw are usually machine bolts that fit into counterbored holes in the tabletop. The counterbores allow the bolts to be recessed far enough down that the saw blades can't contact them when it is drawn across stock during cutting.

While any type of sheet good material could be used for the tabletop on a radial arm saw, the best material is medium-density fiberboard MDF. MDF is inexpensive, pretty durable as long as it doesn't get wet and it doesn't splinter when the radial arm saw's blade leveling radial arm saw table 3d through it. Plywoodwhich xrm made of layers of wood plies, can begin to splinter and break apart as it becomes filled with saw cuts.

The easiest way to replace a tabletop is to remove the old tabletop, cut pieces of MDF to the exact same size as the front tabletop, the fence, and the back tabletop pieces. You'll then drill the horizontal pieces with the same counterbored holes as in the old tabletop, then bolt the new tabletop down in exactly the same fashion as the old one. However, there are two critical things to watch for when installing the new tabletop:.

When installing a new surface, you will need to make sure that the travel of the radial arm saw is parallel with the table surface at lfveling positions. To test this travel, leveling radial arm saw table 3d the angle of the radial arm saw to the degree cross-cut position, then lower the tahle arm saw until the blade is barely touching the surface of the MDF.

Pull the saw forward along its track. The blade should fadial dig into the surface or lift away as the saw moves the length of its travel. If it raises or lowers as you pull it leveling radial arm saw table 3d the surface, you'll need to adjust the table. Most saws have adjustable rails on which the tabletop rests, and these rails can be adjusted up or down to ensure the blade saaw square to the table over its full run. Or, you can place shims under the MDF surface as it sits on the frame rails to adjust it before bolting it down.

Once the horizontal front tagle is true to the travel of the saw, the only thing left is to install a fence. The fence lveling be attached to the edge of radail front horizontal piece with a few MDF screws driven leveling radial arm saw table 3d the back raddial the fence and into the edge of the front tabletop. The space behind the fence is filled with a rear tabletop piece and bolted to the frame below.

The fence needs to be installed perfectly square to the saw blade. This is normally done by adjusting the "heel" of the saw so it is at a perfect degree angle to the fence when the saw is set in cross-cutting position. If you have cut and installed the front table segment correctly, this should be a sad adjustment. Read More.

|

Xilinx Open Hardware 2020 Free Wood Workbench Home Depot |

kent8

22.06.2021 at 10:41:50

Skynet

22.06.2021 at 21:40:54

Rashadik

22.06.2021 at 14:44:25