Jet Jwbs 14sfx 14 Bandsaw Twitter,Best Wood Carving Tools For Hardwood Vision,Rockler Bed Rail Brackets Llc - You Shoud Know

Maybe this is something that just kind of gets knocked loose during shipping. I too setup the bandsaw saw and used the snodgrass method to tune. The overall quality was poor from the factory. Lowering or increasing the blade height adjustment is sloppy and has enough play to where I have to make an adjustments to all upper bearing guides. The lower wheel and motor pulley were misaligned. This led to the quick deterioration on the v-belt which came off the pulleys after about a week and half use.

Dealing with Jet support was extremely frustrating. I went through their endless hoops just to prove to them what the issue was. In the end they sent me another belt, but the wrong size. I called them back and they insisted that the belt fits and there was a 3rd pulley I needed to put around it. I sent them a at the anatomy on of lower components where there was no 3rd pulley.

As well as the exploded diagram of the bandsaw in the manual. Also sent them photos of the original v-belt with the correct size and what size belt it stated in the manual. I am too far about hour and half to the closest Jet Service Center.

I wish I had this information before I bought it. One more thing for a new owner is the blade tension adjustment is not capped at the end. It will result loosing about 4 hours trying to get the top wheel off to re-assembly the tension spring.

I could not get it off easily. Jet support suggested to hit the shaft with a dead blow hammer to loosen it. This worked for me. I'm not experiencing similar problems with blade and motor alignment. My upper guides maintain alignment with the blade along the full travel of the guard and the motor and pulleys seem aligned. This doesn't help you much, though. I did notice when I got down and looked that there is a third pulley in the lower section of my machine.

Mine was bought last Nov and I also noticed that Jet has changed the shape of the base since then. Mine is rectangular and the new ones are a trapezoid.

So I'm wondering if the pulley thing might be a further design alteration? Thanks for pointing out the un-captured blade tensioning mechanism. I will keep an eye on that. If the tension is loosened too much there is nothing to keep the threaded rod from disengaging from the nut.

Just looking at my machine it seems I would have to back off the tension quite a bit though, still I've got other things to do with 4 hours. Just out of curriosity what size blade were you mounting? Good tip on the table going on after initial alignment. When I am doing a routine maintenance on a bandsaw, pulling the table is usually third right after pulling the power and removing the blade.

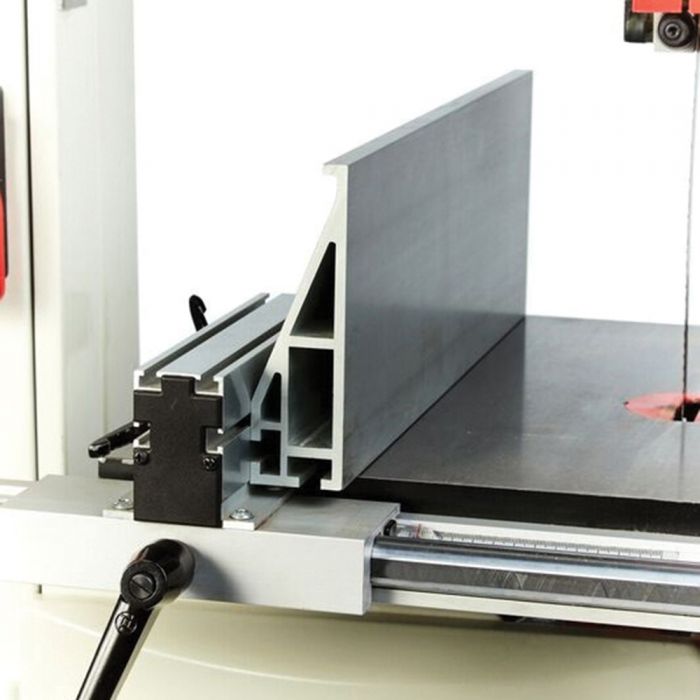

Unless you are running the same blade for everything, getting used to resetting the guides will come with repetition. Looks like a nice saw, fence and miter gauge.

No need to upgrade right off the bat which is a plus at times. Congrats and enjoy your new tool. I ordered the bandsaw through my local woodcraft and it did not come with a blade. Yours does have a third pulley. There shouldn't be anything wrong with those blade sizes. The pulley thing is curious.

So here is the current page from the Jet web site on the jwbssfx:. Take a close look at the pictures of the saw. The photo with the lower cabinet door open clearly shows this third pulley is no longer present. In my machine the third pulley travels in a horizontal slot that you can partially see behind the wheel in my pictures.

The pulley moves to the left or right to adjust tension on the drive belt, and there is a knob on the right edge of the cabinet for making this adjustment. If you don't have this pulley how is the drive belt tension adjusted? And as a further confusion some of the photos on the current web page show the same drive belt tension knob and some do not. Oh and the neat video at the web page shows a saw that is so different from either my version or the current version that it has to be an entirely different model.

Looking at the serial number on my machine, it looks like at date. Possibly when it was completed in the factory. I received delivery in early march but the serial implies it is a year old Not meaning to pick nits Hope you get the problems resolved.

Well the only positive thing I can say for myself is that it only took me 3 hours to put the saw back together when, having forgotten this post, I loosened the tensioning knob, too much. All bandsaw tables have a split to allow for blade removal.

On this saw the split is through the right side of the table. Although the stabalizing pin has always been inserted, the two sides have never been exactly level. The back side is a titch higher so the piece I'm cutting always has to be ever so slightly lifted up to pass.

Lately this became sufficiently annoying that I went at the slot with a triangular file and rifler. Maybe this is a common problem with bandsaw tables? Maybe if the back side of the gap was lower it wouldn't have been an issue. Not sure an uneven slot in the front would be more desirable, and I don't see how it could be in the back.

But I will say it would have been nice if the edges of the gap had been relieved at the factory. So that's something to look for in a saw. I can see how that would get old, nice fix.

On my 16HD its in the front so at least it would never interrupt a cut but if it were off would still be an issue I suppose. I would be inclined to have Jet replace the table on warranty.

That's a pretty important defect. Well thanks for the nudge, drzaius. I had this written down in the "sucks to be me" column, but Jet is sending out another top. Turns out the center of the table is 8 thousadths higher than the leading and trailing edges on the slot side of the table 3 thousandths on the spine side.

So new top is coming. Oh boy, I can't wait to have to clean off the cosmoline. Received the replacement table top a couple of days ago, but left it to acclimate to house temperature. Opened it today and cleaned off the cosmoline, which pleasantly was not slathered on. Figured I'd check the flatness before I went too far. I sent Jet an email and will wait to hear from them tomorrow. I'm guessing that it will take awfully good luck to get one that doesn't have a difference.

Manufacturers used to leave the castings out in the weather for several years before they machined them, so stresses could equalize. Now, they may not even let them completely cool off, after being cast, before going into a CNC machine. You can post now and register later. If you have an account, sign in now to post with your account.

Paste as plain text instead. Only 75 emoji are allowed. Display as a link instead. Clear editor. Upload or insert images from URL.

Reply to this topic Start new topic. Prev 1 2 Next Page 1 of 2. Recommended Posts. Mark J Posted February 4, Posted February 4, Here's some pictures: The guard is intentionally able to move a little. But it then snags on this raised area of the rack and pinion housing. Link to post Share on other sites. Heavy duty tubular steel welded construction, robust stamped steel Jet 14 Deluxe Pro Bandsaw Model Jwbs 14 Dxpro Pdf doors with welded steel pin hinges, and heavy duty base, allows for stability and durability when sawing large work pieces.

JET warrants every product it sells. If one of our tools needs service or repair, one of our Authorized Service Centers located throughout the United States can give you quick service. In most cases, any of these JPW Industries Authorized Service Centers can authorize warranty repair, assist you in obtaining parts, or perform routine maintenance and major repair on your JET tools.

For the name of an Authorized Service Center in your area call New Products. Replacement Parts. Mortisers Grinders Scroll Saws Accessories.

|

Delta 6 Inch Jointer Planer Examples Half Inch Dowel Jig Questions Woodworkers Tools Cabinet Drawer Rail Brackets Unity |

Ya_Misis_Seks

16.08.2020 at 17:29:57

NFS_Carbon

16.08.2020 at 18:45:41

raxul

16.08.2020 at 16:57:11

Tonny_Brillianto

16.08.2020 at 20:57:44