Jet Air Filtration Review 5g,Crown Woodturning Tools Review 01,Slide Out Kitchen Drawer - How to DIY

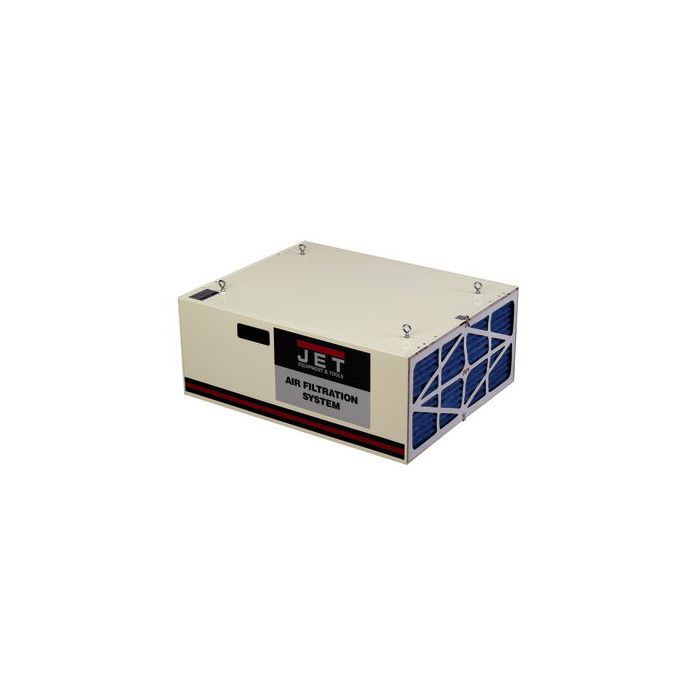

The powerful fan has three speed settings for , , or CFM. It has a similar remote control to the others and has timer settings for 1, 2, or 4 hours. The system is contained in a sturdy steel housing with 4 hanging eyes and a handle for easy transportation. The Powertec AF weighs It runs very quietly, which is something most users have commented on. This is a quality item and matches the other two smaller air filtration system in every aspect. It would be a tough call to say which one is the best.

Your decision will probably boil down to brand preference or the price. The standard Powertec warranty agreement stipulates a period of 1-year for the warranty and a day money back guarantee. The Shop Fox is in the same league as the other two cheaper options and is also a robust little machine in a tough steel housing. It has basically the same performance as the other two, albeit from a slightly less powerful 0.

The filters work in the same way with a 5-micron outer filter and a 1-micron inner filter. It has a remote control and has timer settings for 1, 2, or 4 hours. It also has hanging hooks and a carrying handle like the others. Changing or cleaning the filters is just as easy as Jet Air Filtration System Model Afs 1000b Review For any of the others and replacement filters are also easy to come by. It has a 2-year warranty — the same as what you get for the WEN and better than the Powertec 1-year warranty.

In a workshop that uses cutting, grinding and sanding equipment, dust in the air is inevitable. This is most common in woodworking shops where large amounts of sawdust and woodchips are released into the air as we work.

Shops that deal with stone have a bigger problem because many stone products release minute particles that contain crystalline silicone and the health effects from inhaling silicates is particularly dangerous. This is also true for contractors who cut masonry and stone on site. The main effects of dust or sawdust in the air is that they cause damage to the respiratory system, resulting from particles collecting in the lungs.

Breathing in any amount of dust over a prolonged period can cause irreparable damage to your lungs. Other health problems can be scratching of the eyes and, in some cases, skin irritation. Most woodworking shops will use dust extraction systems that are connected to the machine — usually dust collection bags attached to a vacuum system.

These systems are very effective and remove a lot of the wood-chips and sawdust released by the tools that we use. However, there is always dust that is not collected by a conventional dust extraction system. Small particles of 5-micron or less become airborne very easily and these particles are the most dangerous — causing the most damage to our lungs.

They are too small to see and will go by unnoticed unless they are in large volumes. This causes a fine mist in the air. Because most of the fine dust is not collected by regular dust extraction systems, a secondary air filtration system is of great importance.

Not only are particles in the air a cause of health problems, but they can also have a negative effect when applying finishes and paint to the final product.

In the US, indoor air quality regulations are a legal requirement for employers in two states — New Jersey and California. Despite the lack of federal legislation for air quality in the workplace, labor law does state that all workers have the right to a safe and healthy working environment. By default, this means that if the air in the workplace poses a health risk to your employees, you are in contravention of the law — no matter what the state laws are.

This is why any workshop that produces dust Jet Air Filtration System Model Afs 1000b Review Union needs an air filtration system that is capable of removing dangerous particles from the air. This means that it needs to have the correct filters, normally removing particles of up to 1-micron in size. To give you an idea of what this is, 1 micron is 0. For most shops, a 1-micron filtration system is fine for solid matter particles. An HEPA filtration system will remove particles of 0.

Your workshop air filtration system needs to clean the air in the shop times per hour. This means that the entire volume air in the area needs to pass through the air filtration system at least six times every hour. An air filtration system uses a fan to draw air through the filters and release it back into the atmosphere as clean air without any harmful particles.

To do this you need to calculate the volume of your shop Length X Width X Height , you then multiply this by the number of times you want the air to be cleaned and divide your final answer by Installing an air filtration system is not complicated. Larger units may require a V circuit and may also require heavier mountings as these will be heavier machines.

Generally, people prefer to hang the air filtration system from the ceiling and most of the smaller models have eyes or hooks to make this easy to do.

Placing the filtration system too close to a wall or workbench will obstruct the airflow. This will provide the best air circulation around the room. Maintenance of your air filters is critical to ensure that the system works properly.

Air filtration systems have filters that are designed for cleaning and are usually very accessible and easy to remove and replace. This can be done by using compressed air or a vacuum cleaner. You should check these filters to see how often they need cleaning, maybe with every third work session.

A filter can be cleaned many times, but at some point, they need to be replaced. Outer pre-filters need to be replaced more often. Air filters are not expensive and are usually very easy to get.

If you buy an air filtration system from a reputable brand, you should never have a problem obtaining replacement filters. The International Air Transport Association says in a briefing paper that the filters are "effective at capturing greater than 99 percent of the airborne microbes in the filtered air. But Teague's proposed design takes things a step further, creating an invisible germ isolation unit with "blades" of air. The company is calling it "AirShield," and it functions similarly to those warm or cool air curtains you may have noticed while walking into airports or retail stores.

While those are typically meant to keep cool or warm air inside to control the temperature in a space—or keep bugs and smoke out—the AirShield concept creates a barrier around each set to disrupt the normal flow of air. That creates a de-facto shield for coughs, sneezes, or any other particulate matter, immediately directing it downward and out of the cabin to the HEPA filtration units. Enter those overhead jets, which also go by the awkward name "personal air gaspers.

To take advantage of that concept, Teague had to play around with the shape and position of the air jets, eventually engineering a "grill" of 3D-printed nozzles that technicians can simply retrofit over the existing air gaspers. Your typical single-deck airplane also features an underfloor area for the ambient air, so as the AirShield system directs blades of air downward—along with any particulate matter—the HEPA filtration system can carry the discarded air to the floor, forcing it outside the airplane.

In a side-by-side computational fluid dynamics analysis, Teague found the concept "effectively redirects respiratory emissions to the floor. In the 3D simulation, the system looks at two rows of seats on the starboard side of a single-aisle aircraft. AirShield has a constant flow rate of 0. A single breath from a passenger's mouth is represented by a velocity of 15 meters per second.

Under these conditions, a single breath was effectively cast downward. Of course, this is the company's own data, so take it with a grain of salt. However, compared to some of the other concepts we've covered, AirShield looks like it really could be a breath of fresh air. Type keyword s to search. Today's Top Stories. Navy Destroyers Encountered Mysterious Drones.

|

Porter Cable Pocket Hole Jig 560 Yamaha What Products To Clean Hardwood Floors Make Finger Joint Jig Router Table Kit The Weekend Woodworker Cost Meaning |

gagash

30.04.2021 at 16:58:18

160

30.04.2021 at 14:43:28

elnare

30.04.2021 at 10:20:36

DunHiLL

30.04.2021 at 11:43:45

18_USHAQ_ATASI

30.04.2021 at 16:44:57