Finger Joint Jig Router Diy 5mm,Installing Butler Tray Hinges Pdf,Hardware Stores Open On Christmas 3d - Review

If you finger joint jig router diy 5mm create box joints, or a woodworker looking to give this strong, versatile joint a goone of the best tools you can have at hand is the box joint jig. However, with such a wide range of jigs currently available it can be difficult to decide which one to buy. Below you will find our table of results comparing roiter of the best box joint jigs on the market. The box joint is a handy alternative to the dovetail.

They are strong, aesthetically pleasing and actually easier to achieve than their more highly regarded cousin. Box joints are made up of alternating pins and sockets. They essentially fit together in a system where one piece of jkint has the pins and the mating piece has sockets.

Box joints excel in situations where you need reliable, well made joints finger joint jig router diy 5mm a number of items. Fast, efficient production is the name of the game here. However, there is a technique involved when cutting pins and sockets in such a uniform manner at speed.

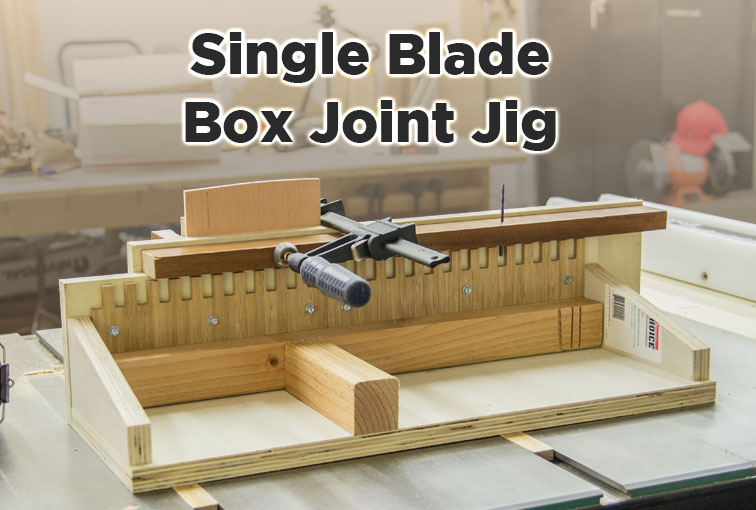

There is no room for error. Thankfully, routerr are mig available to make the work almost fool proof. In steps the box joint jig. The jig makes it possible to make controlled, paper-thin adjustments on your work pieces, positioning them in a manner so that both the pins and sockets finged be cut with perfect precision. If you want professional box joints to look immaculate, the box joint jig is the tool you need to buy.

There are a number of issues you should consider when buying a box joint jig. However, considering precision is so important when it comes to using one of these jigs, many woodworkers choose to buy one route the many reputable brands that manufacture them, our top joinh Incra I Box being one of the most popular choices. Again, the better jigs will be able to handle a range of thickness, with the finger joint jig router diy 5mm end being greater than what the cheaper alternatives offer.

You should check the specifications before you hand over any of your hard earned money. Who really wants to be finger joint jig router diy 5mm in this way?

Kig best box joint jigs will offer maximum flexibility as far as compatibility goes, and will work under all manner of work style configurations. A sturdy build quality really should be prioritised as this is a tool you will want to carry on using for jgi to come.

It is also one of those tools easy to neglect when it comes routr overall care, haphazardly chucked into the tool boxor left loose in the back of the truck, you name it, the jig is likely to take a beating from time to time.

This all means you should opt for a tool with a good reputation when it comes to durability. While the materials used to build the jig are important, user reviews really will help ascertain how the jig holds up over time. The fact is, without reliable, repeatable precision cutting of pins and slots, your box joints will be sloppy and ill-fitting.

To achieve the best results your chosen jig must have a smooth-sliding, incremental backer sled, as well as precision-machined indexing keys. Only finger joint jig router diy 5mm well made tool with offer that peace of mind. The price of box joint jigs does finger joint jig router diy 5mm a lot. The incra i box jig for fnger joints is one of the most expensive on the market, however it is clearly a consumer favourite and is one of the most highly regarded jigs finger joint jig router diy 5mm can buy for this purpose.

Whether you buy an Incra or opt for something cheaper is very much down to personal preference finger joint jig router diy 5mm budget. While the lower budget tools do achieve the same goal, the speed, repeat cut reliability and overall flexibility of a premium tool should not be ignored.

There are different types joont box joint jigs; and their material quality, scope of functions, and quality of cuts differ. Using quality box joint jigs improves the overall workmanship. Moreover, the well-made box joints improve the aesthetics of ringer final assembled woodwork product. Incra I-Box Jig is an affordable, lightweight, and portable box joint jig designed and manufactured by Incraa leading maker of woodworking tools. It is designed to create intricate well-fitting box joints.

Incra has also added additional safety features in this model, including a transparent blade guard joimt protects the worker from flying wood chips. Likewise, this model is designed for quick set-up. It measures 21 inches in length, 15 inches in width, and 4 inches in height. It weighs about 7 pounds. It features a compact design that allows for greater versatility that permits the worker to use this model for advanced decorative joinery.

It is recommended that one watches the instructional DVD before using the jig as it provides the right instructions of how to set up the box joint jig, and also shows how one can finger joint jig router diy 5mm the joing of the jig.

The user manual also describes how the Incra I-Box fiy setup on table saws and router tables. This means that this model can be used with either a table saw or a router table as its platform. Once the Incra I-box Jig is set up on its platform, a stacked dado set needs to be fixed. The Incra I-Box is incompatible with wobble dado blades.

However, all its other tool requirements support use of mainstream tools including router bits. The model also features a patented Incra GlideLock which allows its miter bar to fit into the standard miter slots of the platform. Even though the Incra GlideLock support standard miter slots, it finger joint jig router diy 5mm allows for an adjustment of between 0. Incra I-Box features aluminum extrusions, and its fence is 2.

Joinf 0. The chart card provided with this model lists assorted pin widths, appropriate width of workpiece, and number of fingers. The workpiece can be easily fitted into the Incra I-Box fihger, and a set of properly-measured rectangular cuts made. Because this first workpiece does not feature any half-cuts, its rectangular cuts are described as the sockets.

Next, the first workpiece is used to prepare the second workpiece for cutting. The rectangular cuts in this second workpiece funger the pins, and they are expected to fit into the sockets of the first finger joint jig router diy 5mm and then form a well-fitting box joint.

Box joints are extremely size-sensitive. This size-sensitivity increases exponentially as the amount of fingers increase. If the pins is exactly the same size as its corresponding socket, then mig woodworker would need to apply a lot of force to force the pins into their sockets, and the resulting box joint would be super tight.

However, a very small allowance in the sockets allows the pins to slide in perfectly. Incra I-Box Jig has a specially designed adjustment dial and knob which allows for minimum width changes of 0. The knob is a silver wheel that features a thin slit. This slit is used to guide the woodworker royter many graduations the knob has been turned from the zero mark.

The dial is calibrated with silver marks with each mark denoting a 0. Therefore, to increase the size of the socket by 0. This makes the socket 0. To improve the strength koint the joint, wood glue is applied between the finfer of finger joint jig router diy 5mm pin and socket that are in contact. Tinger ability to make very fine calibration gives the Incra I-Box Jig an edge over other box joint jigs. If ordinary box joint jigs are used, the woodworker or joiner would need to use coated abrasive materials such as routre for sanding the sockets so that pins can readily fit in.

However, this risks creating an uneven surface or excessively enlarging the size finger joint jig router diy 5mm the sockets so that the worker ends up with a loose box joint. Incra I-Box Jig is a Made-in-America box joint jig designed to be used by both beginner and veteran woodworkers to make diiy wide variety of well-measured box joints ranging from simple joints to intricate decorative box joints. Due to its durability, quality material design, and ability to make accurately shaped and sized sets of pins and sockets, the Incra I-Box Jig is rated as the best jig for box joints dig the five 5mk joint jigs being reviewed.

This model of router finger joint jig router diy 5mm is made by Rockler Companiesa reputable provider of woodworking tools. It is rputer made for making precise, tight-fitting, and well designed box joints. Moreover, this model is designed for quick set-up. It measures It weighs about Like Incra I-Box, it eouter features a compact design that allows for greater versatility that permits the worker to use this model for decorative joinery.

This model is shipped alongside its easy-to-understand instruction manual. The instruction manual describes how the Rockler box joint jig is to be setup on router djy, and how the user can achieve optimum results while using this rouher. The Rockler box-joint jig has a low-friction melamine-coated MDF platform. This improve its durability, as well as makes it easy for the worker to clean it. Router tables use bits, while table saws use stacked dado blades which can fihger easily spaced in order to achieved the desired pin width.

Also, unlike Incra I-Box which supports mounting on non-standard miter slots, the Rockler router-table box-joint Jig can only be fitted on a router table that has a standard 0.

The Rockler box-joint jig comes with precision-machined aluminum index keys. They are three in number, and are of varying sizes. These indexing are used for positioning the jig as well as create a quarter inch, three-eighth of an inch, and half-an-inch spacing for making air-tight joints.

Like Incra I-Box, it supports a maximum wood stock width of 0. This model features a pre-drilled right-angle backer which operates as the miter gauge, joont well as doubles as cinger platform where the sacrificial board is secured onto using screws.

This ensures that the workpiece koint Finger Joint Jig Router Diy Youtube well guided towards or away from the router jig. It also provides ample support for the workpiece. This sled backer is made from ABS plastic. There are two sacrificial boards that come with it. Another unique feature of Rockler box-joint jig is its easy-grip knobs which are well-positioned on the MDF platform and are used to securely lock this platform onto the miter slot.

The Rockler Router-Table Box-Joint Jig is an easy-to-use device designed to be used by both beginner and veteran woodworkers to make a various well-measured box joints. Its simple and clean design finger joint jig router diy 5mm unique features allows it to be versatile. Woodhaven box-joint jig is a portable easy-to-use tool for making properly-fitting box joints of various sizes. These box joints can be made in all sizes of wood, including large ones.

|

Jet Plane Weight Status Woodworking Tools Germany Inc Makita 18v Multi Tool Problems Router Tool For Sale Linux |

Torres

24.06.2021 at 19:18:31

Sevimli_oglan

24.06.2021 at 10:15:31

TeNHa_H

24.06.2021 at 22:45:53