Dust Collection System Gates Data,Rockler Circle Cutting Jig Instructions,Digital Electronic Tape Measure 75,Wooden Dowel Pin Sizes Java - How to DIY

This dust collection tour is to hopefully inspire you. Take a look at your own dust collection system and improve upon it if it needs it. So, in an effort to stay healthy in the shop I wanted to improve my dust collection situation.

I just knew I wanted a better solution for my shop and tools. Number one, there are other videos out there on the cyclone assembly. Secondly, the installation manual for the cyclone goes over the assembly process step by step.

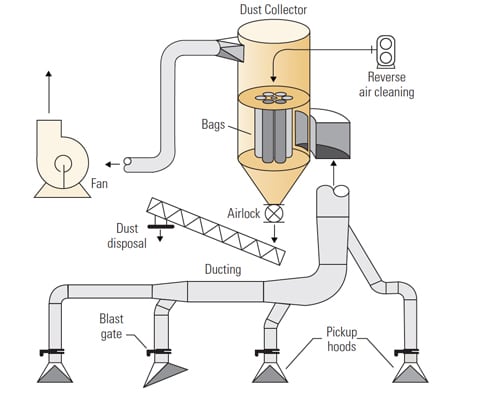

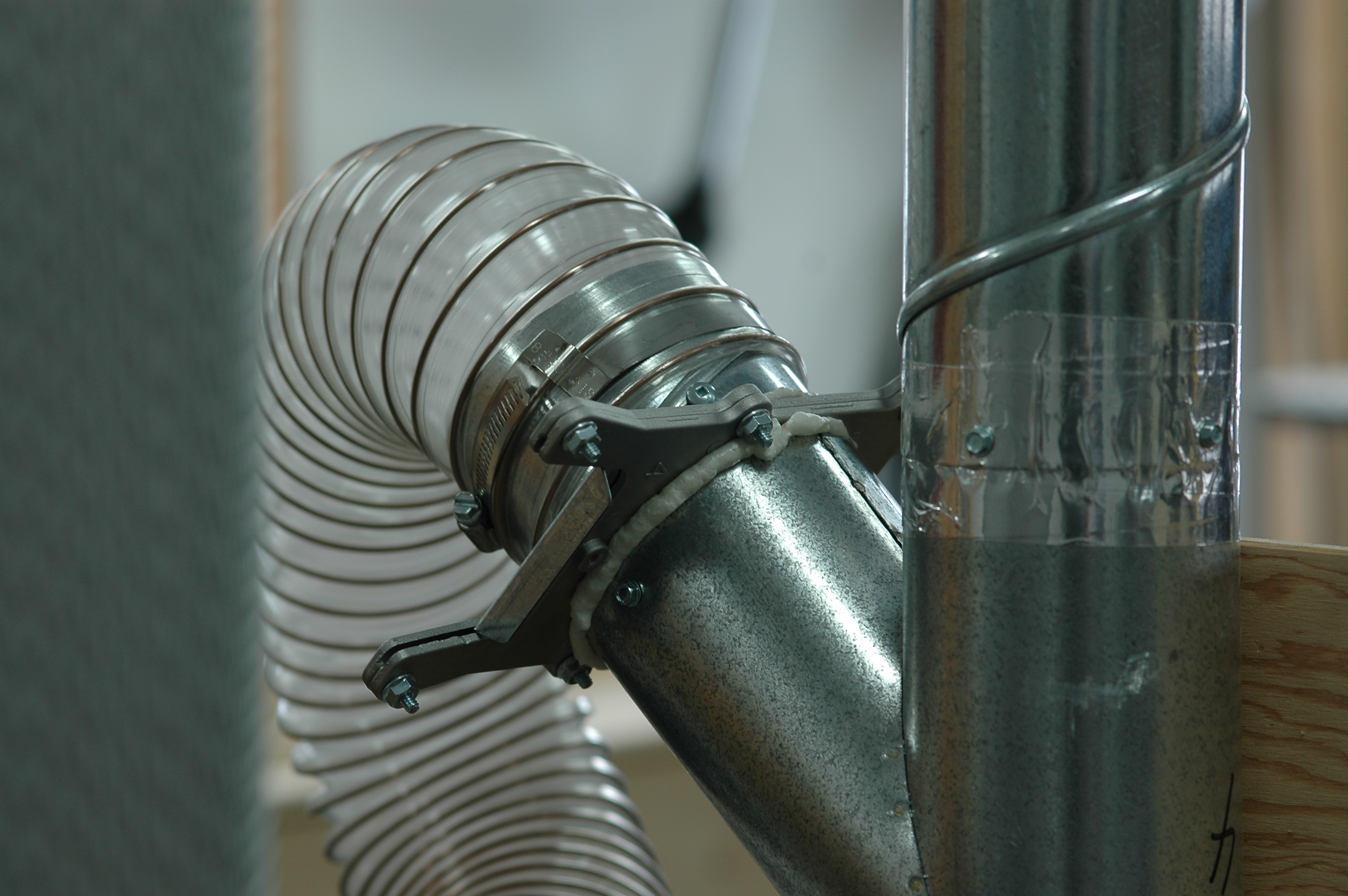

The installation of the pipes is a matter of connecting fittings into the pipes. The configuration will be different for everyone. Listed below are links some are affiliate links to the tools mentioned in this dust collection tour. The most important part of a dust collection system is the dust collector itself. I decided to go with all metal dust collection pipe this time instead of some metal and some plastic. For the main trunk line diagonal across my shop ceiling I went with six inch solid pipe.

I ended up having one main trunk line with two splits, meaning I used a wye fitting in two different locations to go towards other tools. I used more six inch solid pipe from those locations dust collection system gates data far as I could go.

Some instances I had to use another lateral to gain access to dust collection system gates data tools. The metal flexible pipe comes in six and four inch, both five foot lengths. A good place for the flexible metal pipe would be in an area where you might have to move the pipe slightly in one direction or another. For example, if you saw the video, you saw that I have a section of the metal flexible pipe over my lathe to move the dust hood I have installed around for different reasons.

Another good place might be an overhead port for a table saw, but only if you support the pipe with an arm or supported with a bungee from above. I think you get the idea. For each section of five foot solid pipe used I had to use either a coupling or a fitting of some kind to continue with the pipe.

In my previous setup plastic blast gates were dust collection system gates data. I had to repair several with tape and glue because they started separating.

So, using metal blast gates in this system is quite the treat. The metal blast gates I used are so much more rigid obviously, but one thing the plastic blast gates had that these metal ones do not is the self cleaning feature.

Self cleaning means the open hole would extend out past the housing of the gate in the closed position. So, when the gate was in the open position it would look like the gate was extra long.

This allows for the gate itself to push any dust or debris out and avoid any clogs. Gates that are not self cleaning run the risk of pushing dust and debris into the slot where the gate closes. This causes the gate not to close all the way leaving a small opening and not sealing.

Being a dust collection project and video, I thought it was only fitting to include FilterBuy. FilterBuy is the sponsor of this post and is definitely dust collection system gates data the business to clean the air just like my new dust collection system.

Give FilterBuy a look and tell them I sent ya. FilterBuy is a dust collection system gates data owned Grizzly Woodworking Dust Collection Systems Data business and all their filters are made right here in the U.

Plus, all orders are shipped free within 24 hours. Check them out here. When installing the solid pipeespecially by yourself, it can be tricky. I started by inserting the first pipe into the cyclone intake. On the other end of that dust collection system gates data pipe I screwed some wire to the ceiling in order to hold the pipe from falling. I did this for each piece I added including the fittings and did not tape anything other than a small piece here and there to hold things from coming loose.

Doing this allowed me to figure out the best route of dust collection for my tools and it also made it easy for me to change things around before securing everything permanently with wire to the ceiling. Because of the cyclone intake, the first pipe was lower than the rest of the pipe in the system. Clearvue actually suggests a five foot run of dust collection system gates data before any dust collection system gates data or turns for the best performance.

I would suggest trying to use more forty-five degree bends dust collection system gates data of any ninety degree bends. The more turns and bends you have in the system the less your system will work at full capacity. Both the solid pipe and the flexible pipe came in five foot sections, so in areas where I dust collection system gates data shorter pieces of solid pipe I had to cut it to length.

First, I would measure what length I needed, make marks around the pipe and then connect those marks to create a line I could follow with my jigsaw. I would start the cut with a hacksaw just in one small area.

As soon as the blade made it through the metal, I finished the cut with a jigsaw using a metal cutting blade. Using my leg vise on my outfeed table, I opened it just enough to hold the pipe. Besides that, I could spin it in place as I held the jigsaw and to also manage the pipe while cutting it.

I did this for the metal flexible pipe as well. Each tool drop was a little different because of different configurations. Branching from the main trunk required a lateral fitting, which is common.

After the lateral is where things can get convoluted. For example, at the center of my shop I have two drops coming down, but a total of five ports. One drop is simple, a straight run through dust collection system gates data blast gate onto a sole tool, the jointer. The second drop is leaving a lateral connected to a true six inch wye. That wye is connected to two Clearvue transitions one six to two fours with blast gates.

These transitions are designed to allow a connection to a single tool with two four inch outlets or two tools with four inch ports each. From these transitions I connected clear four inch flex hose to the tools. In this case it was my down draft table and my router lift. In most cases I tried to install them as close to the dust collector or cyclone as possible.

Keep in mind the direction of the blast gate when installing them. I wanted to make sure from where I stand at the tool I could reach up dust collection system gates data over to pull on the lip of the gate. The lip is only bent one way, so making sure how you will interact with the gate is important before taping it in place.

The screw can be placed on either side. As I mentioned when installing the pipes I started out by temporarily using wire and a little bit of tape to hold things in place.

When it came time to secure everything permanently, I started by taping the joints and seams closest to the dust collector. I then worked my way out towards the tools. As I stated in the video, the X-Carve already had a good dust collection setup with Inventables dust shoe. I was using a shop vac and that seemed to work just fine. Adding the cnc to the cyclone meant convenience and also freeing up the floor space my shop vac was claiming.

The X-Carve is connected to the same Clearvue transition as my planer, which has a four inch to two and a half inch reducer. When using the X-Carve I open both four inch ports on that transition to avoid starving the cyclone for air. The planer has a blower in the ejection port, so the chips have a little extra help getting back to the cyclone. I have no issues with either of these tools and dust collection.

Each four inch port has a clear flexible hose attached at the transition. As one of the messiest tools in my shop dust collection system gates data than the lathe, my miter saw improved the most in terms of dust collection.

Mainly because this miter saw station is my newest addition to the shop. I designed it with dust collection as a priority. It features removable outer panels, which allow you to cut ninety degree cuts without removing them and forty-five degree cuts by removing the panels. These panels allow for maximum dust collection and as the video shows, it works great.

To check out the project plans for the miter saw station click here. I have a six inch flexible metal pipe attaching the dust box to the main trunk line of the system. The six inch metal blast gate is between the flexible metal dust collection system gates data and a six inch stovepipe take off.

In turn that is connected to the dust collection system gates data saw station dust box. With an open six inch port there, it is moving some air.

This port is extended from the miter saw station dust collection system gates data a six inch flexible metal pipe.

Having the twenty one foot expandable hose and floor sweep allows me to dust collection system gates data up after dust collection system gates data the lathe, but also around the shop.

Hands down. Reasons I like it is because it dust collection system gates data so much storage. It also has two tools integrated into it, which are the router and downdraft both with dust collection.

From the drop next to my jointer is the dust collection system gates data for my outfeed assembly table. This gives me two four inch dust collection system gates data at the outfeed assembly table and two four inch ports for the table saw. At this location is the router and downdraft connections.

Both are connected with clear flexible four inch hose at the tool on one end and the Clearvue transition at the other end. When using either of these tools I will open both blast gates to allow the cyclone proper air flow. Side note, I thought about hot glueing a strip of wood to both gates to make it more convenient to open the gates at the same time.

|

Table For Sewing Machine Online 500 Laguna Bandsaw Accessories Mod Scrap Deck Wood Projects Pvt Ltd |

sauri

17.01.2021 at 21:29:43

Sabishka

17.01.2021 at 12:23:12

PENAH

17.01.2021 at 23:36:36